A gear shaving tooth profile error prediction method

A tooth shape error and prediction method technology, applied in the field of gear processing, can solve the problems of reducing the efficiency of the shaving process, relying on sharpening technicians, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] It should be noted that the specific embodiments described below are only used to explain the present invention, but not to limit the present invention, and the present invention is not limited to this embodiment.

[0067] This embodiment provides a method for predicting tooth profile error of shaving gear, which mainly includes the following two steps:

[0068] Step one: Prediction model of tooth profile error:

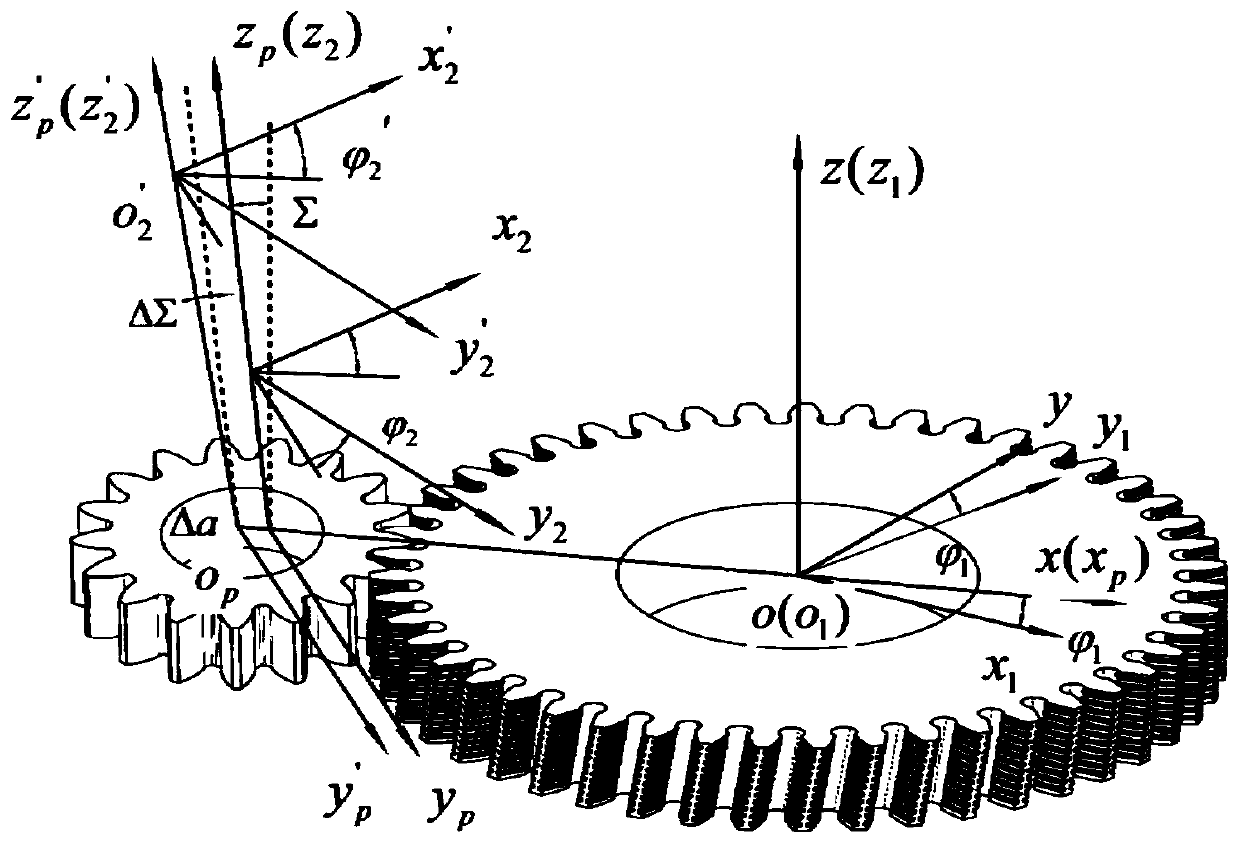

[0069] S1: Coordinate transformation with installation error of shaving gear

[0070] In order to facilitate subsequent derivation, a coordinate system for gear shaving processing is established with installation errors. figure 1 Shown. Among them, S(o-xyz) and S p (o p -x p y p z p ) Are two fixed coordinate systems in space, S 1 (o 1 -x 1 y 1 z 1 ) And S 2 (o 2 -x 2 y 2 z 2 ) Are the moving coordinate system of the fixed connection between the gear shaving cutter and the workpiece gear. According to the space geometry, the conversion relationship between the coordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com