A Proportional Valve Online Zeroing Method

A proportional valve and zero-adjustment technology, which is applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve problems that affect the smooth production and unstable operation of proportional valves, so as to save adjustment and test time, reduce Maintenance workload and reduction of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

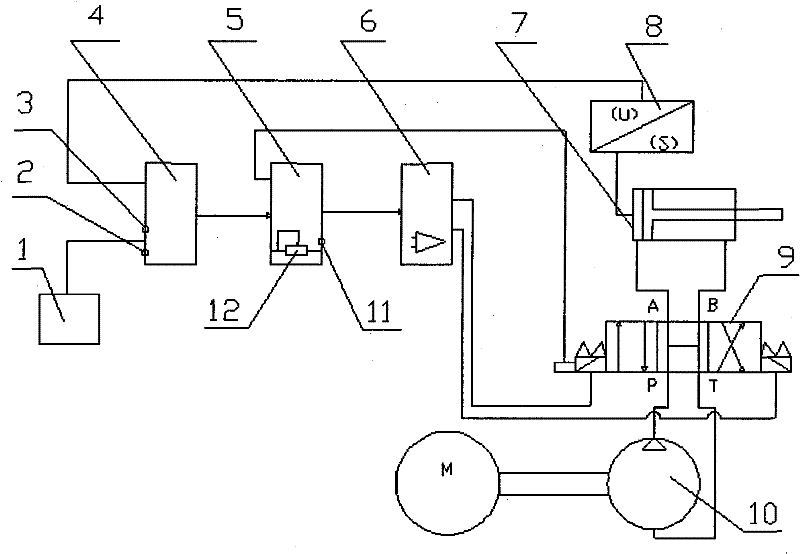

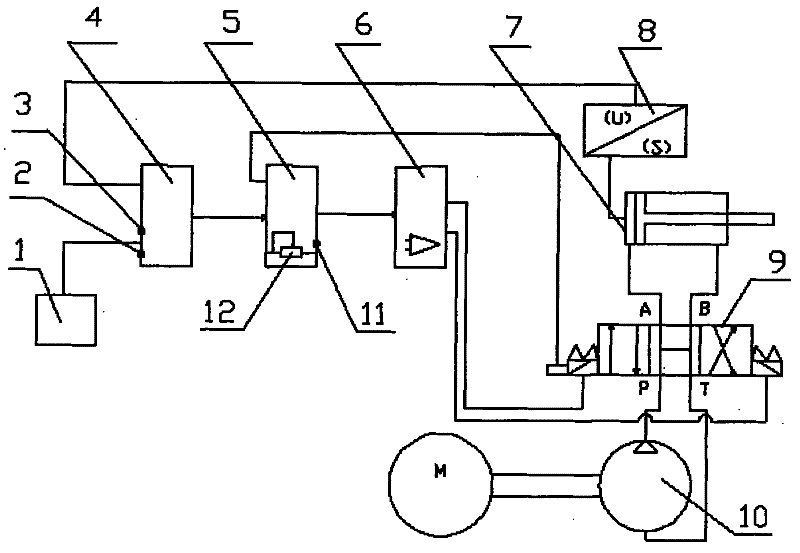

[0016] Below, the present invention will be further described in conjunction with the accompanying drawings.

[0017] It can be seen from the drawings that the entire proportional valve feedback control system is mainly composed of the continuous rolling system programmable logic controller (PLC1), proportional amplifier board I4, proportional amplifier board II5, power amplifier 6, hydraulic cylinder 7, sensor 8, hydraulic valve 9 And hydraulic pump 10 constitutes. The proportional amplifier I4 is mainly responsible for the position control of the cylinder rod of the hydraulic cylinder; the proportional amplifier II5 is responsible for the position control of the proportional spool. Measuring point II2 and measuring point I3 are respectively set on the proportional amplification board I4, measuring point III11 is set on the proportional amplification board II5, and a zeroing resistor 12 is arranged inside. The sensor 8 is responsible for feeding back the received cylinder ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com