Partition scanning method for thin-walled part additional material manufacture

A technology of additive manufacturing and scanning method, applied in the field of additive manufacturing, can solve the problems of large temperature gradient, warping deformation, large stress of forming thin-walled parts, etc., to improve strength, reduce shape error, and simple control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0046] A partition scanning method for additive manufacturing of thin-walled parts, mainly comprising the following steps:

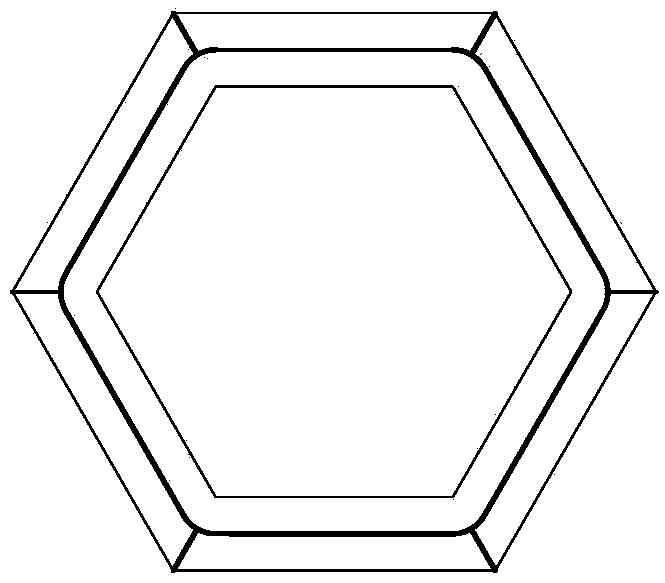

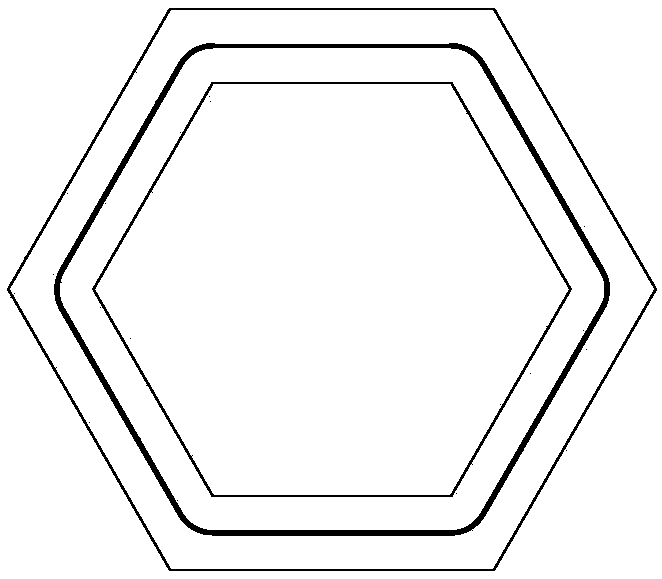

[0047] (1) According to the layered contour data of each layer slice obtained by layered slices of the thin-walled parts to be processed, calculate the central axis transformation of the boundary of each solid area; figure 1 , 4 , The thin solid line shown in 8 is the slice outline, and the thick solid line is the central axis of the boundary of the solid region;

[0048] (2) For the transformation of the central axis of each solid area boundary, according to the size of the area affected by the central axis edge, the central axis edge with less influence is cut; for example figure 2 , 5 , the cutout central axis shown in 9;

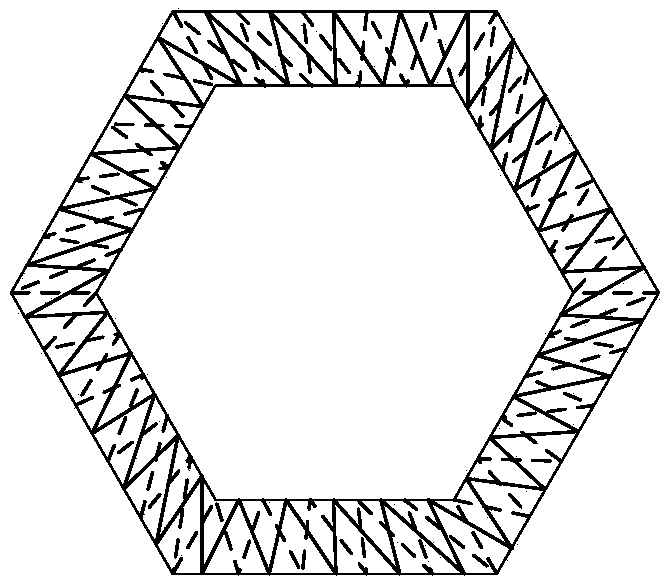

[0049] (3) Determine whether to divide the solid area into multiple main areas and connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com