Method for making printed angle rectangle section steel pipe

A technology of rectangular steel pipe and sharp corners, applied in the field of manufacturing rectangular steel pipes with sharp corners, can solve the problems of large twisting moment, large welding energy consumption, poor welding quality, etc., and achieves easy adjustment operation, uniform current density, and forming error. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The method of the present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

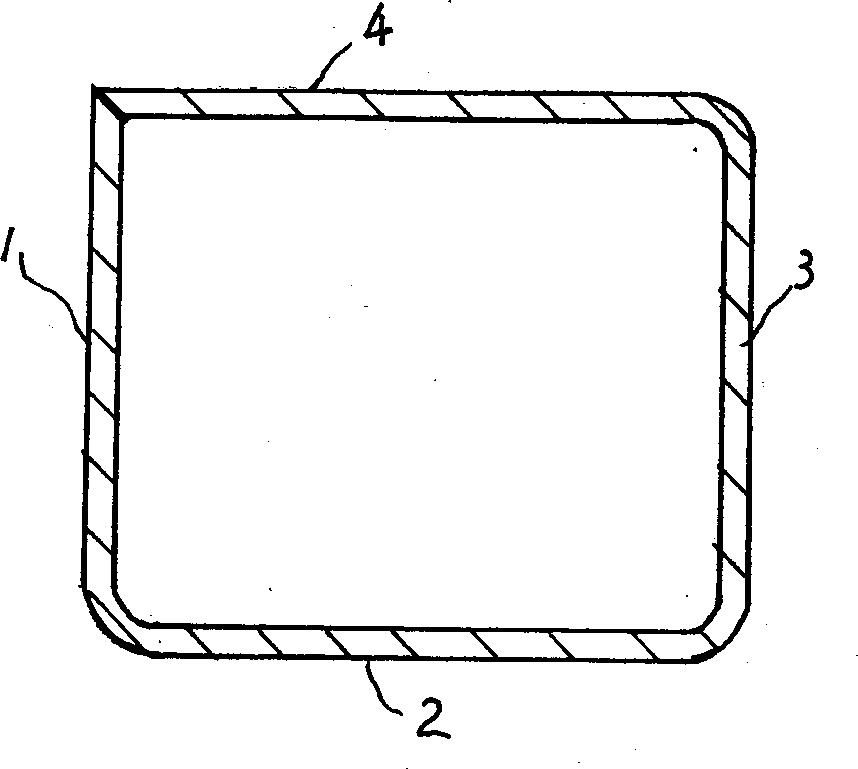

[0010] Made as figure 1 The process of the pointed rectangular steel pipe shown is as follows:

[0011] a. Determine the required strip width and the specific dimensions of each side according to the cross-sectional geometric dimensions of the rectangular tube.

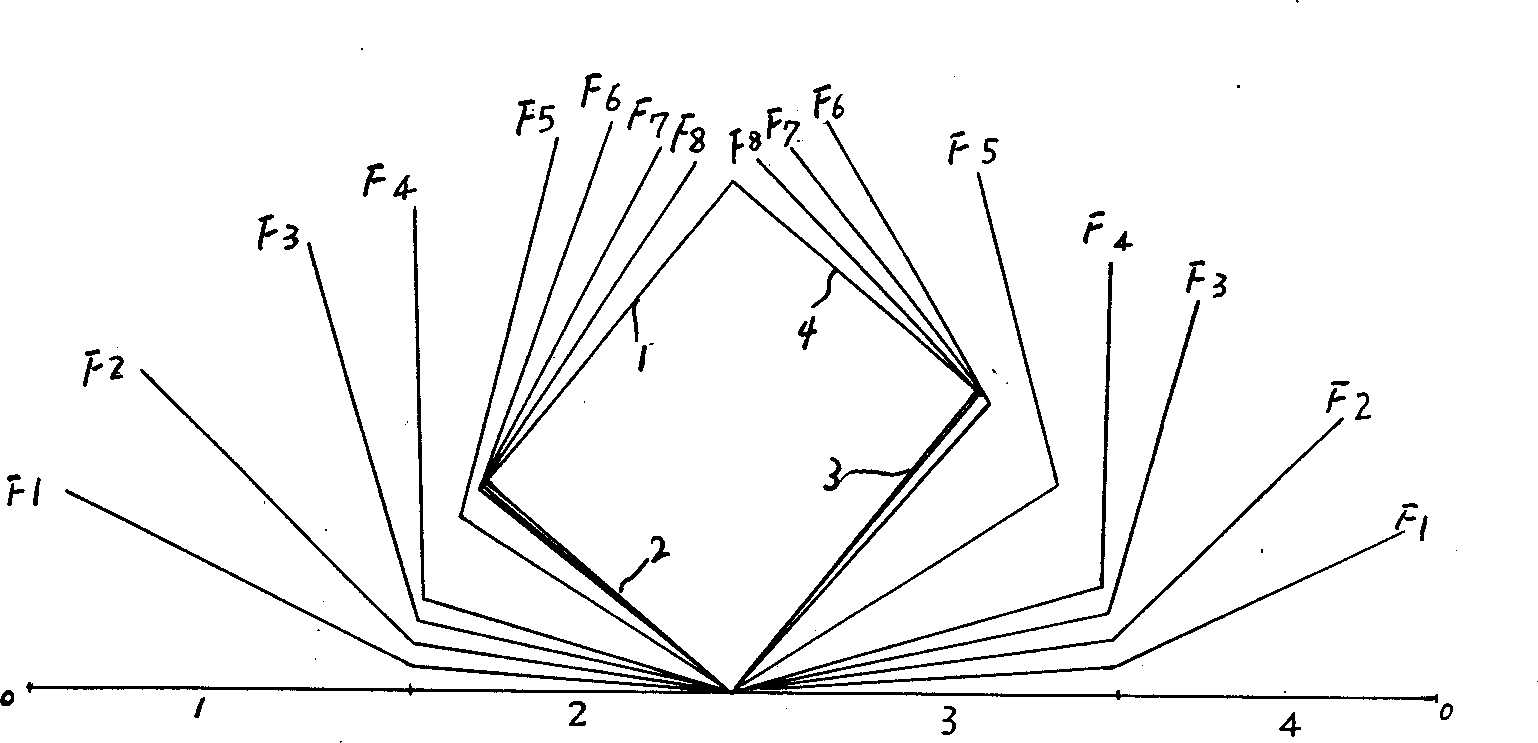

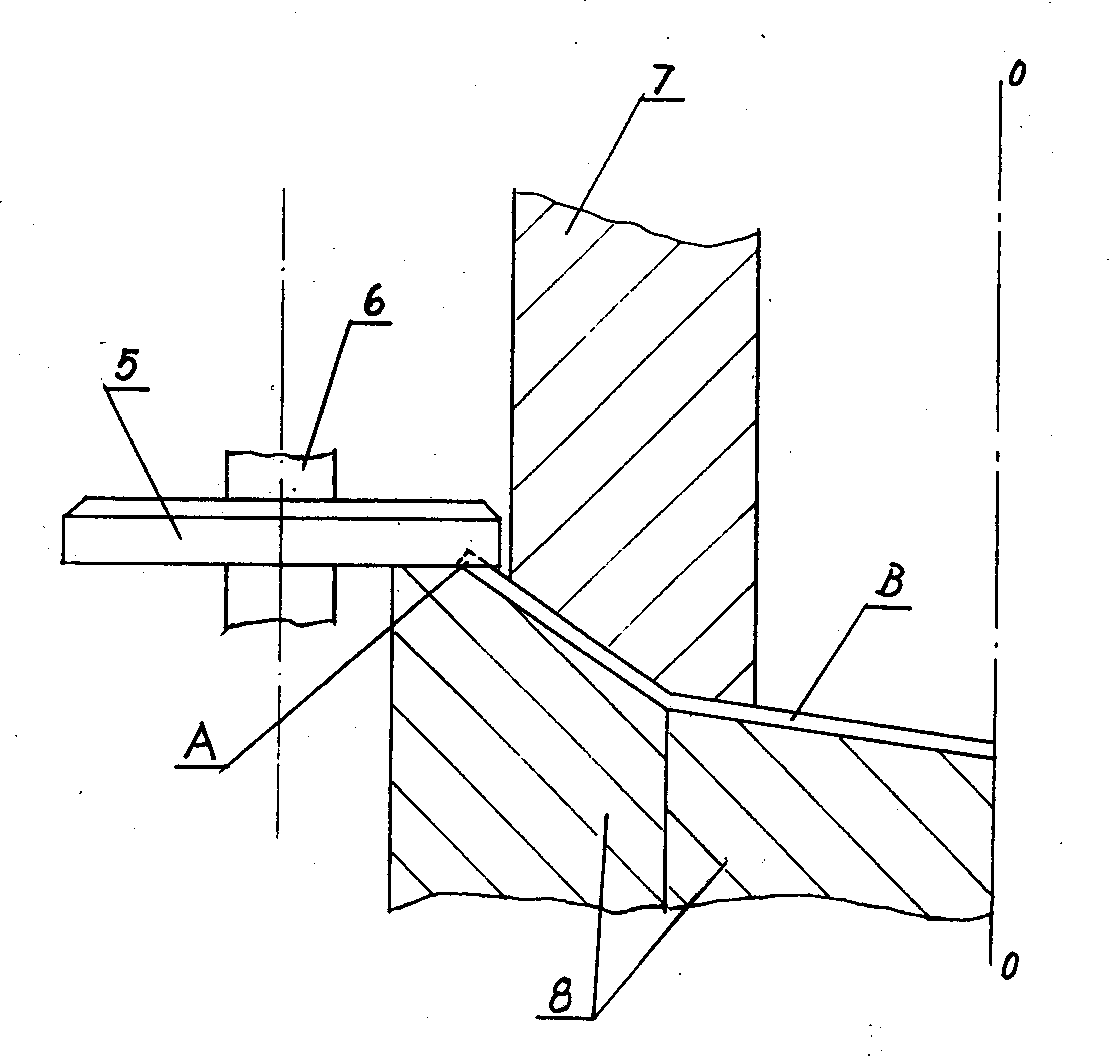

[0012] b. If figure 2 As shown, determine the node positions of the rectangular tube side (2) and side (3), adjust the position of the rolls in each pass so that the roll centerline (that is, the rolling centerline (0-0)) and the side (2), side The nodes of (3) coincide.

[0013]

Deformation pass

Edge (1) and Edge (2)

angle of

Edge (2) and Edge (3)

angle of

Edge (3) and Edge (4)

angle of

Edge (4) and Edge (1)

angle of

F1

159°

172°

159°

F2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com