Method for aligning, online detecting and correcting of gearwheel

A technology of large gears and sliding tables, applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve problems such as time-consuming and laborious, low accuracy of in-position detection and correction, and difficulty in aligning large gears , to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

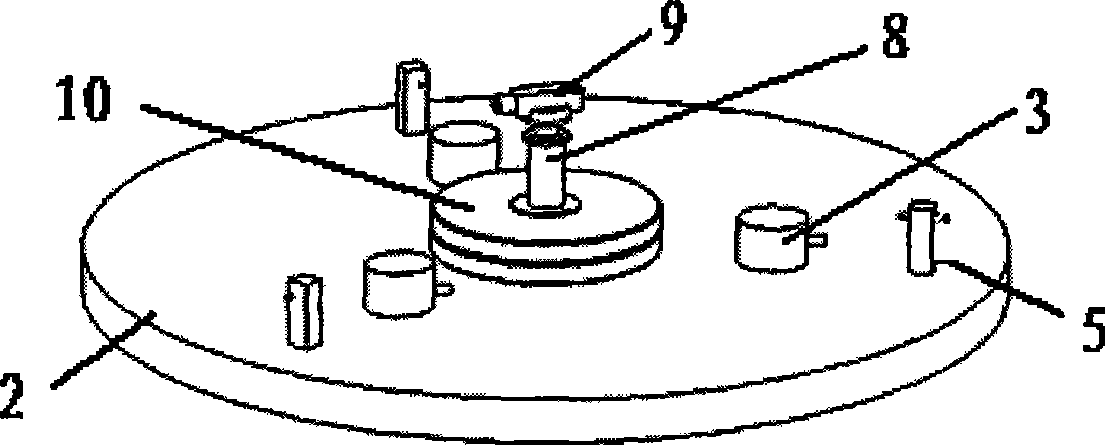

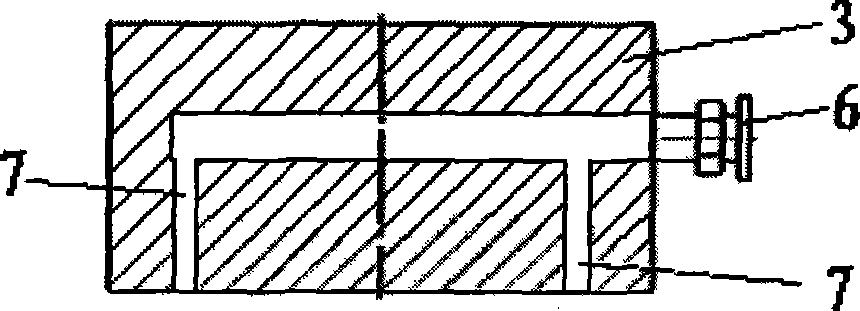

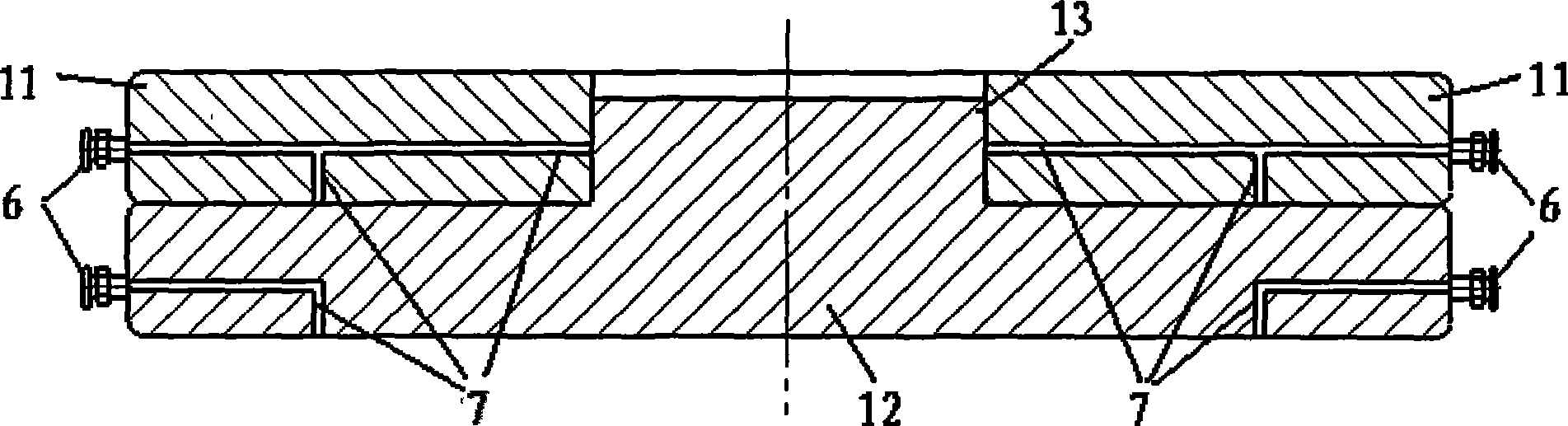

[0028] Such as figure 1 , the structure of the large gear alignment, in-position detection and correction device used in the method of the present invention is that on the upper surface of the workbench 2, a number of air bearing sliders 3 and fine-tuning devices 5 under static pressure are evenly arranged around the same axis, Such as figure 2 , each air bearing slider 3 is provided with a connected air inlet 6 and an air outlet 7, the air inlet 6 is arranged horizontally, and the opening of the air outlet 7 is downward; the setting radius of the fine-tuning device 5 is greater than the radius of the workpiece 1 The fine-tuning device 5 is provided with an adjustment screw, and an air-static air-floating turntable 10 is installed on the axis of the workbench 2. The air-floating turntable 10 is connected to the optical theodolite 9 at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com