Multi-point symmetric vibration progressive composite and precise forming system for metal plate

A metal sheet, precision forming technology, applied in the field of metal sheet multi-point symmetrical vibration progressive compound precision forming system, can solve the problems of slow processing speed, low forming surface quality, uneven strain, etc., and achieve surface quality and forming efficiency Effects of improvement, stress condition and forming conditions improvement, strain rate and forming quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

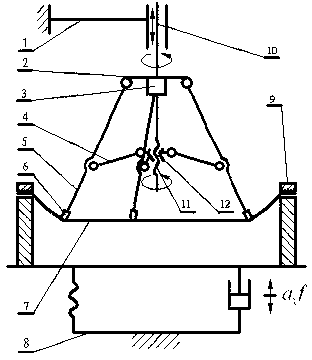

[0020] (1) On the one hand, the main shaft installed on the bed can drive the tool head bracket to rotate around the axis of the main shaft; on the other hand, it can drive the tool head to rotate along the main shaft axis to realize the main movement of sheet metal forming.

[0021] (2) The retractor is installed inside the tool head bracket, and is hinged to the middle of each tool head bracket through a connecting rod.

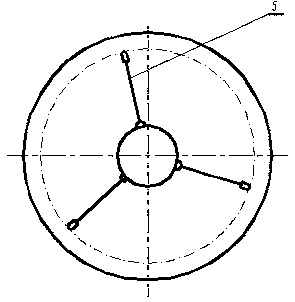

[0022] (3) The nut can move up and down under the drive of the motor, and the tool head bracket is driven to expand and contract in the radial direction through the connecting rod, so that the tool head can move between different levels along the axis of the main shaft while the tool head is rotating. Give.

[0023] (4) Installed under the lower mold (worktable). During the forming process, the exciter vibrates at a certain frequency and amplitude, and applies alternating impact loads to the forming area to realize multi-point progressive compound precision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com