Shape error analytical system and method

An error analysis, analysis type technology, applied in special data processing applications, measuring devices, instruments, etc., can solve the problems of a single form and cannot display each point intuitively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

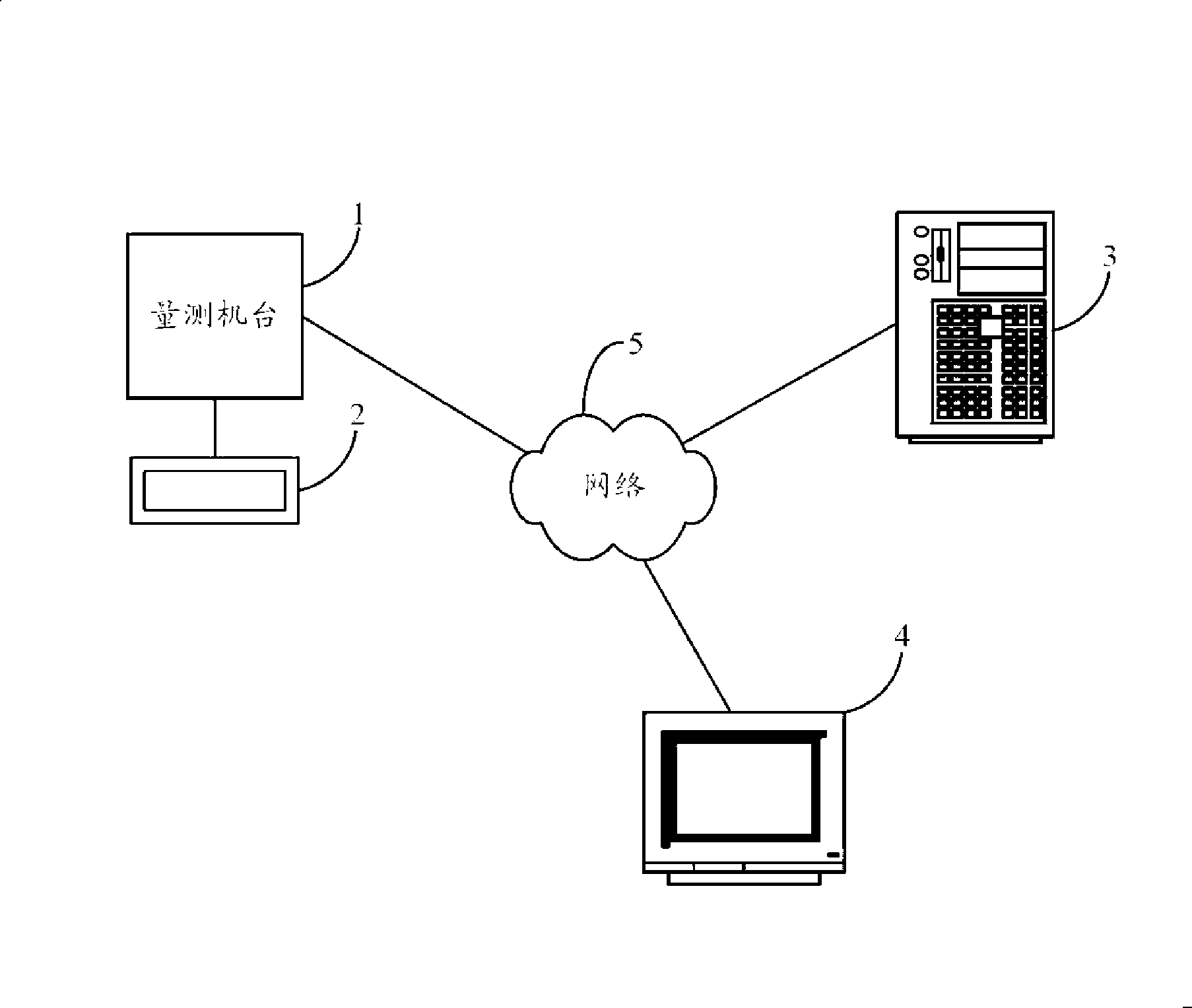

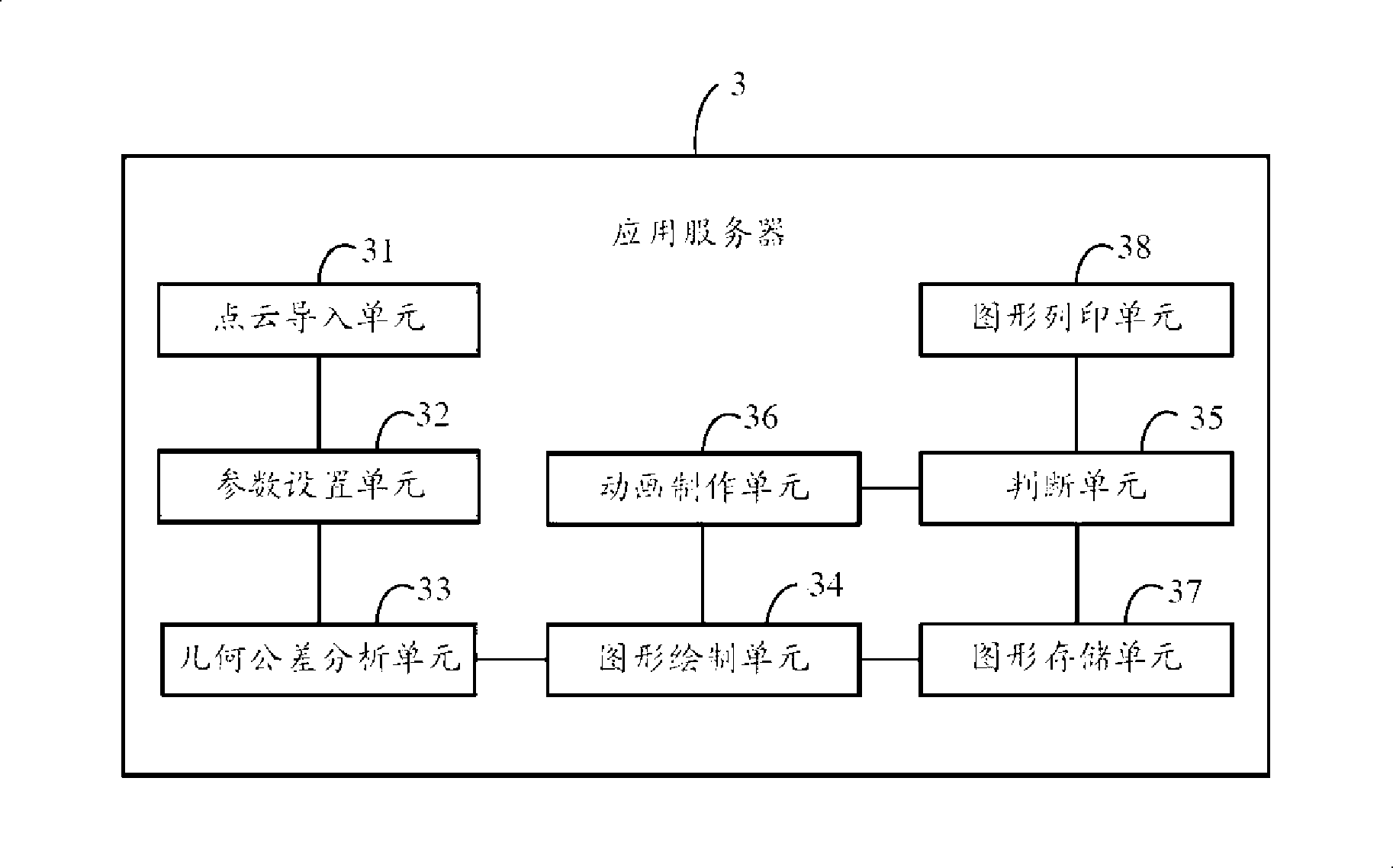

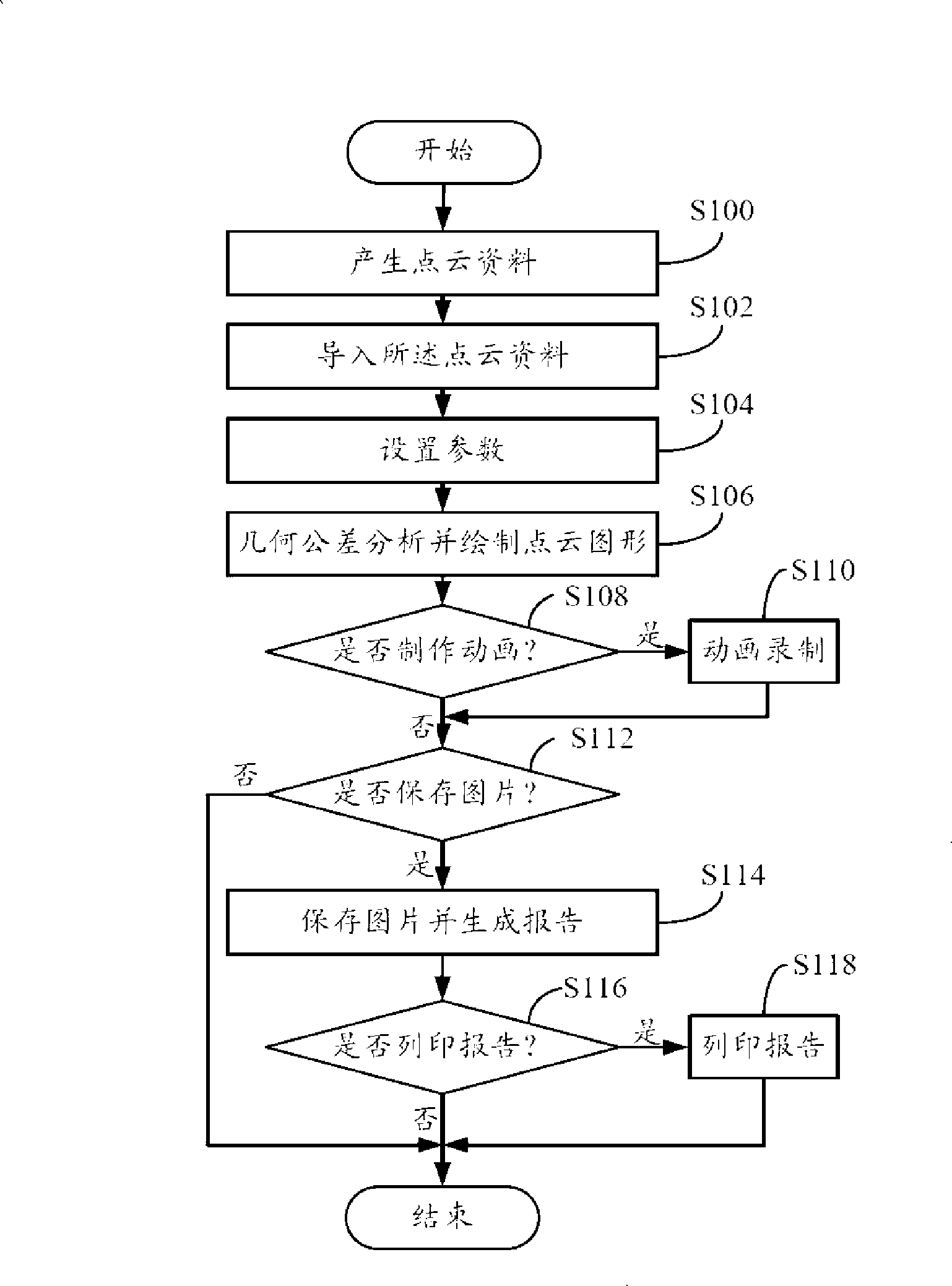

[0014] Such as figure 1 Shown is a hardware architecture diagram of a preferred embodiment of the shape error analysis system of the present invention. The system includes a measuring machine 1, at least one workpiece 2, an application server 3, at least one application terminal 4 (only one is shown in the figure), and is connected to the measuring machine 1, the application server 3, and the application terminal 4 network5. Wherein, the network 5 may be an enterprise intranet (Intranet), the Internet (Internet) or other types of networks.

[0015] The measuring machine 1 in this embodiment can be an image measuring machine or a laser scanner. The measuring machine 1 is used to scan the measured element on the workpiece 2 to obtain point cloud data of the measured element, and the point cloud data is stored in a point cloud file. The point cloud file can be divided into CSV (Comma Separated Value, comma separated value) file, TXT (text) file and QVS file according to its st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com