Global calibration for stereo vision probe

A probe and probe tip technology, applied in the field of global calibration system, can solve problems such as camera frame distortion error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

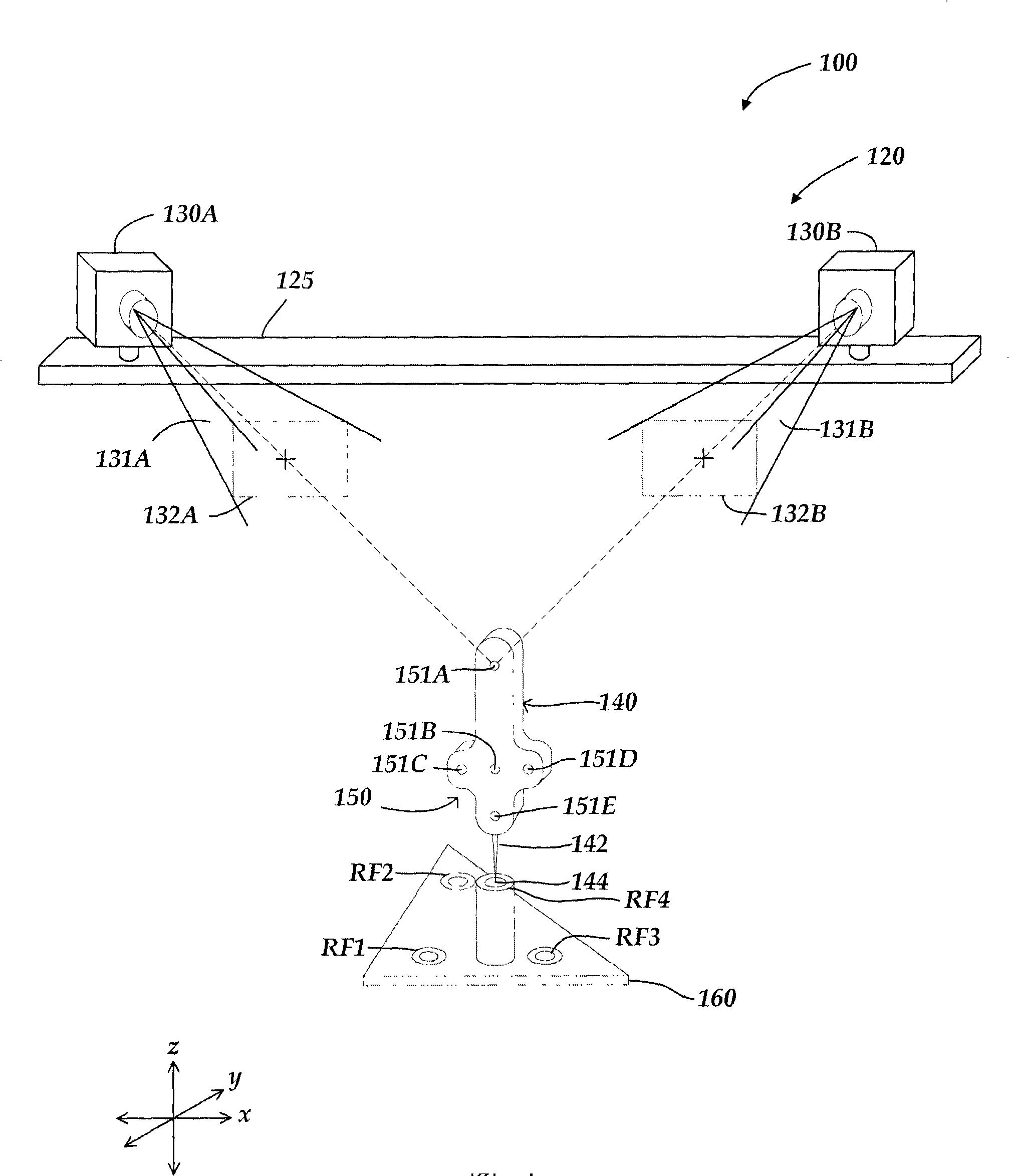

[0023] figure 1 is a schematic diagram of a first exemplary embodiment of a multiview touch probe system calibration arrangement 100 . Since this particular embodiment employs a typical two-camera stereo vision configuration, this configuration is interchangeably referred to as the stereo vision touch probe system calibration configuration 100 . The calibration arrangement 100 includes a stereo vision touch probe system 120 and a portable calibration fixture 160 . The stereo vision touch probe system 120 includes a mount 125 , two cameras 130A and 130B and a touch probe 140 . The body of touch probe 140 includes a marker pattern 150 comprising a series of individual markers 151A-151E imaged by stereo vision cameras 130A and 130B. Each individual marker 151A-151E may include an IR LED s or other light sources or any other type of marker that can be reliably imaged by a stereo vision camera. The end of the touch probe 140 also includes a stylus 142 having a probe tip 144 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com