Non-full-symmetry involute gear, gear cutting hob special for same, and machining method of non-full-symmetry involute gear

An involute gear, incomplete technology, applied in the direction of gear tooth manufacturing tools, gear tooth manufacturing equipment, metal processing equipment, etc., can solve the small curvature radius, affect the tooth root bending strength of the gear, and reduce the tooth root of the intermediate idler gear bending strength etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

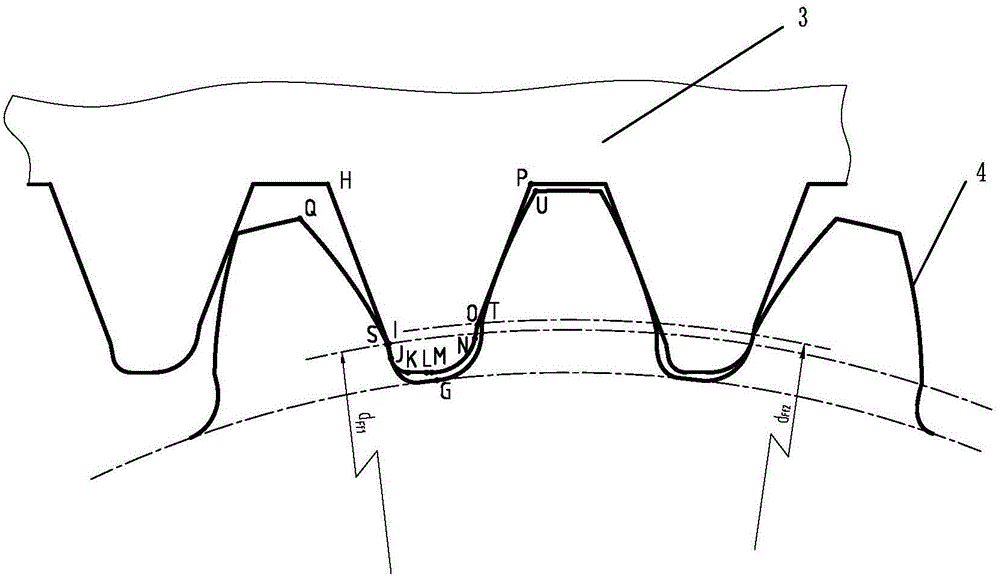

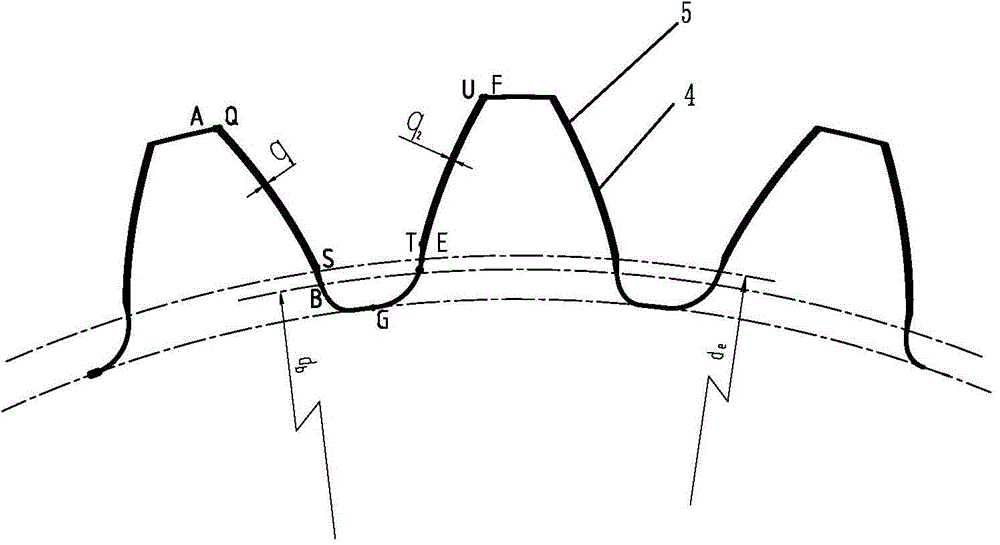

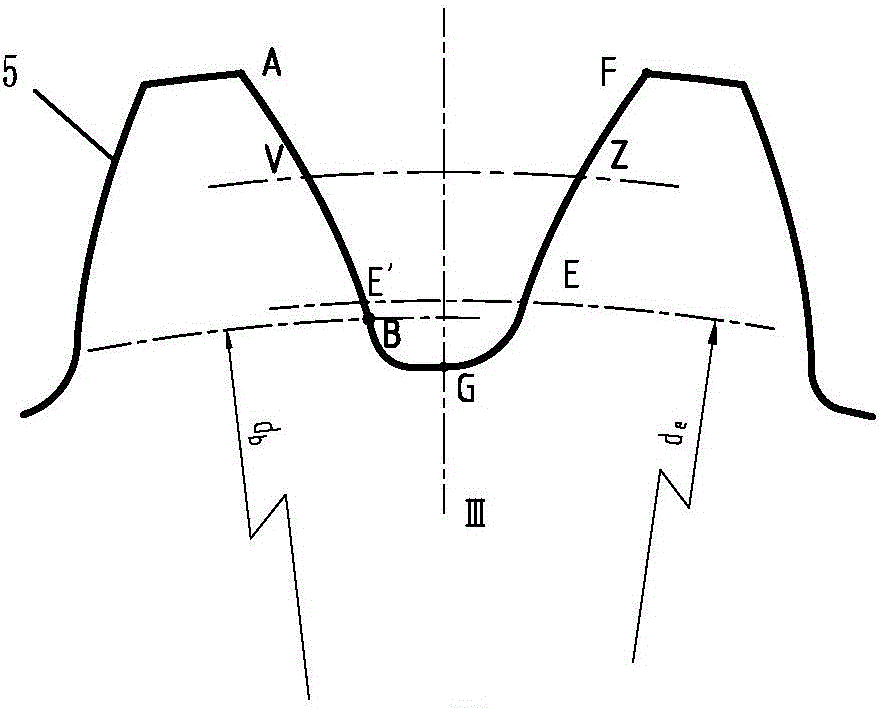

[0034] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, a kind of non-completely symmetrical involute gear processing method of the present invention comprises the steps:

[0035] The first step is to prepare a gear blank 4 that can be used for gear hobbing;

[0036] The second step is to select the special gear cutting hob 3;

[0037]The third step is to use the special gear cutting hob 3 to hob the gear blank 4, and the tool segment where the straight line segment HI of the tooth profile 1 on the left side of the special gear cutting hob 3 is hobbed to form the involute segment QS of the end face tooth profile QSG on the left side of the gear blank 4 , where the straight line segments IJ, KL and arc segment JK of the left tooth profile 1 are located, the tool segment hobbing gear blank 4 left side forms the dedendum curve SG of the end face tooth profile QSG; the right tooth profile 2 straight line segment PO The right side of the hobbing gear blank 4 of the tool segment where i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com