Design calculation method for reverse involute gear transmission meshing

A technology of involute gear design and calculation, applied in the direction of calculation, components with teeth, belts/chains/gears, etc., can solve the problems of short life of gears, low reliability, large contact stress at contact points, etc., and achieve improvement Effects of carrying capacity, relaxing error, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

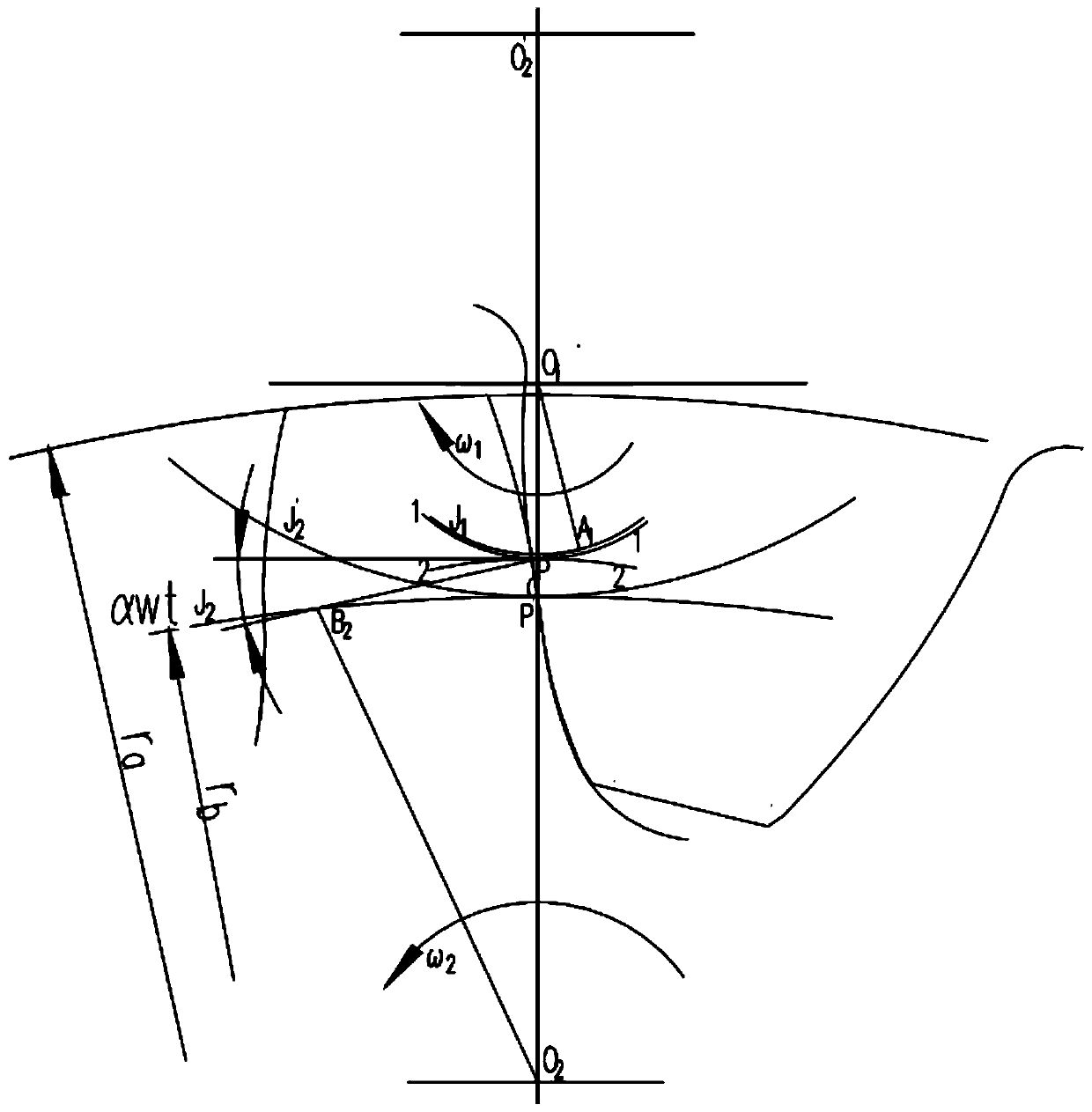

[0473] Embodiment 1: large transmission ratio gear transmission calculation, such as Figure 15 and Figure 16 shown

[0474] The first gear of 6T53 automobile gearbox adopts the improved design of dotted line gear. Transmission input torque 1516Nm (output torque 7200Nm), installation center distance a=123, required transmission ratio i=4.5~5, material selection 20CrMnTi carburizing and quenching, material characteristic coefficient ΔE=8.84×10-6 characteristic system, allowable bending stress [σ] F =420Mpa, allowable contact stress [σ] H =730Mpa, the other parameters are selected according to the standard. According to the calculation, actually determine the pinion z 1 = 8, large gear z 2 =38, modulus m n =5.75, pressure angle α n =22.5°, helix angle β=7°. See Table 1-1 for specific calculations.

[0475] Table 1-1 Point-line gear transmission design calculation table

[0476]

[0477]

[0478]

[0479]

[0480]

[0481] Table 1-2 Gear parameter table...

Embodiment 2

[0489] Embodiment 2: the gear transmission calculation (as Figure 17 shown)

[0490] Steyr drive axle spur gear, center distance a=193, transmission ratio i=1, modulus m determined according to transmission output torque n =5.25, pressure angle α n =20°, the number of gear teeth z 1 = z 2 =35, helix angle β=15°. Adopt the improved design of point-line gear, calculate and determine the modulus m n =6.5, pressure angle α n =22.5°, helix angle β=15°, number of gear teeth z1 =z 2 =31, the tooth width 36 remains unchanged. The calculation process is shown in Table 2-1.

[0491] Table 2-1 Calculation table for gear transmission design with the same number of teeth (i=1)

[0492]

[0493]

[0494]

[0495]

[0496]

[0497]

[0498] Table 2-2 Gear parameter table (dotted line gear i=1)

[0499]

[0500] Table 2-3 Gear parameter list

[0501]

[0502]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com