A Design Calculation Method for Reverse Involute Gear Transmission Mesh

An involute gear, design and calculation technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as low reliability, short service life of gears, large contact stress at contact points, etc., to achieve The effect of reducing difficulty, relaxing error, and improving carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0474] Embodiment 1: large transmission ratio gear transmission calculation, such as Figure 15 and Figure 16 shown

[0475] The first gear of 6T53 automobile gearbox adopts the improved design of dotted line gear. Transmission input torque 1516Nm (output torque 7200Nm), installation center distance a=123, required transmission ratio i=4.5~5, material selection 20CrMnTi carburizing and quenching, material characteristic coefficient ΔE=8.84×10-6 characteristic system, allowable bending stress [σ] F =420Mpa, allowable contact stress [σ] H =730Mpa, the other parameters are selected according to the standard. According to the calculation, actually determine the pinion z 1 =8, large gear z 2 =38, modulus m n =5.75, pressure angle α n =22.5°, helix angle β=7°. See Table 1-1 for specific calculations.

[0476] Table 1-1 Point-line gear transmission design calculation table

[0477]

[0478]

[0479]

[0480]

[0481]

[0482] Table 1-2 Gear parameter table ...

Embodiment 2

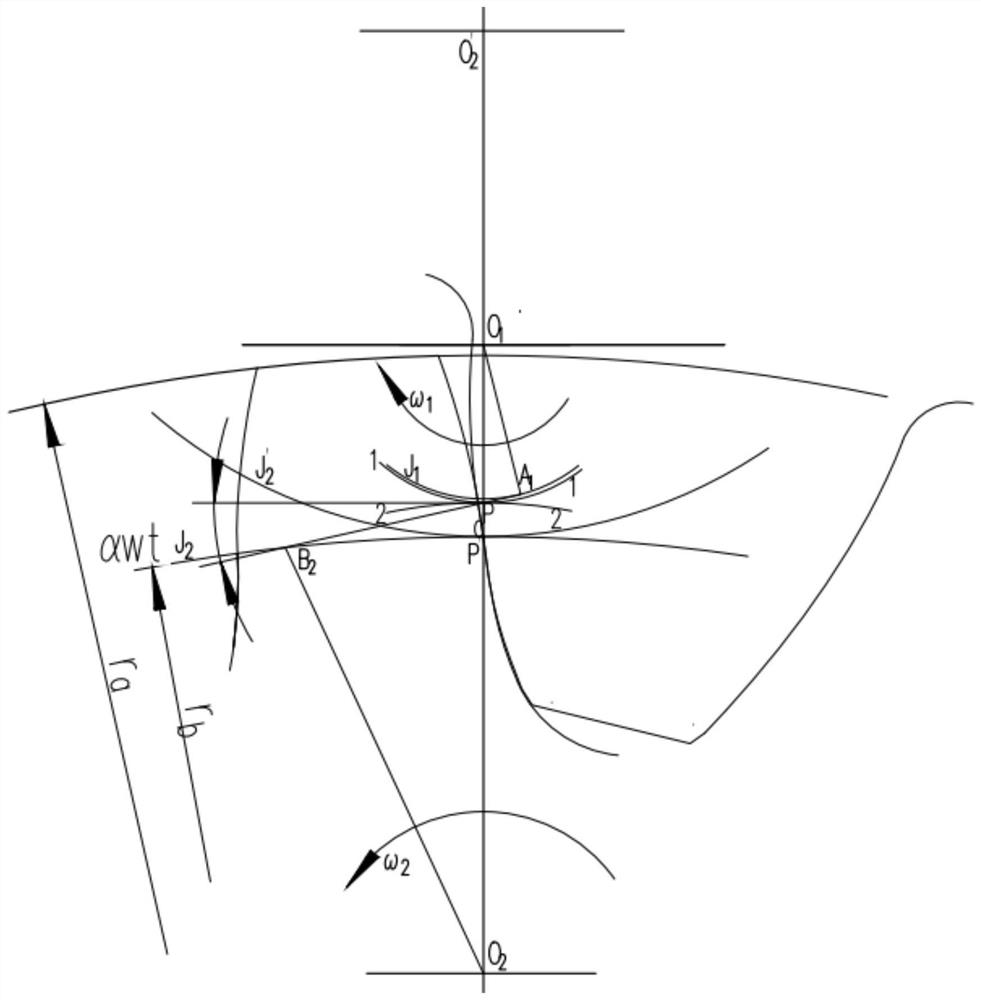

[0489] Embodiment 2: the gear transmission calculation (as Figure 17 shown)

[0490] Steyr drive axle cylindrical gear, center distance a=193, transmission ratio i=1, modulus m determined according to transmission output torque n =5.25, pressure angle αn=20°, number of gear teeth z 1 =z 2 =35, helix angle β=15°. Adopt point line gear to improve design, calculate and determine modulus m n =6.5, pressure angle α n =22.5°, helix angle β=15°, number of gear teeth z 1 =z 2 =31, the tooth width 36 remains unchanged. The calculation process is shown in Table 2-1.

[0491]Table 2-1 Calculation table for gear transmission design with the same number of teeth (i=1)

[0492]

[0493]

[0494]

[0495]

[0496]

[0497]

[0498] Table 2-2 Gear parameter table (dotted line gear i=1)

[0499]

[0500] Table 2-3 Gear parameter list

[0501]

[0502]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com