An anti-involute obtaining method for a gear

An acquisition method, an involute technology, applied to components with teeth, belts/chains/gears, special data processing applications, etc., can solve problems such as low reliability, short gear life, and large contact stress at contact points. Achieve the effect of reducing difficulty, improving carrying capacity and relaxing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

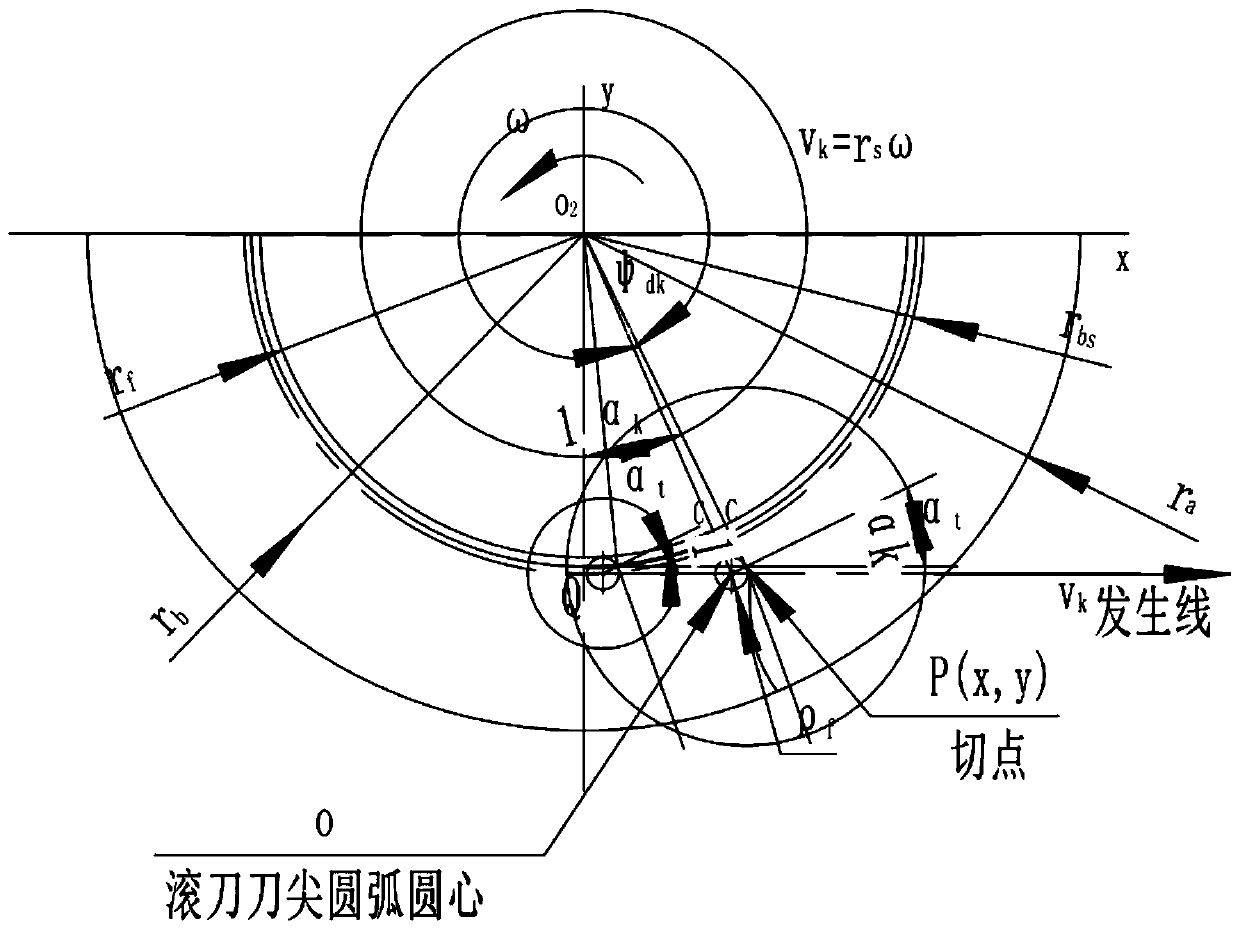

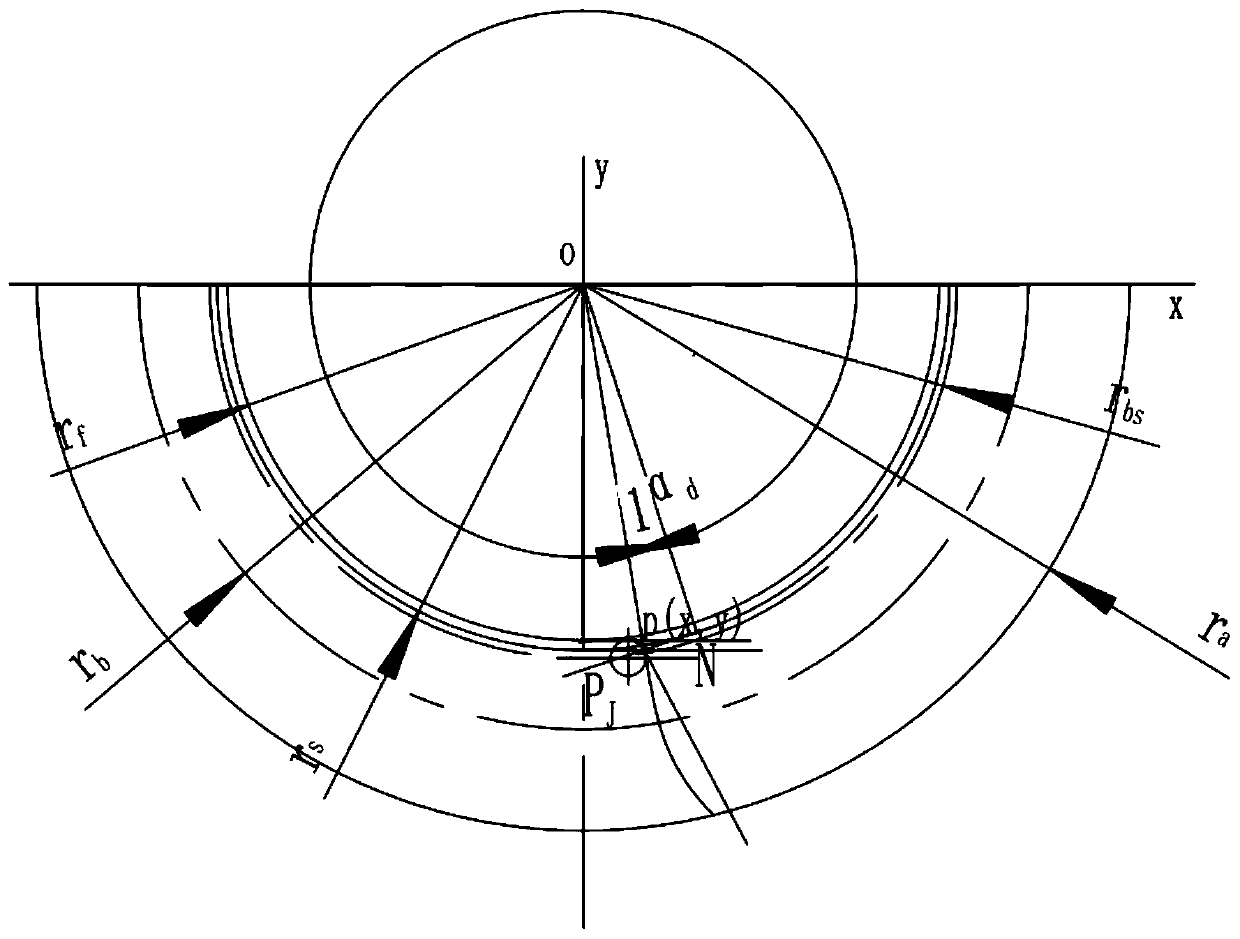

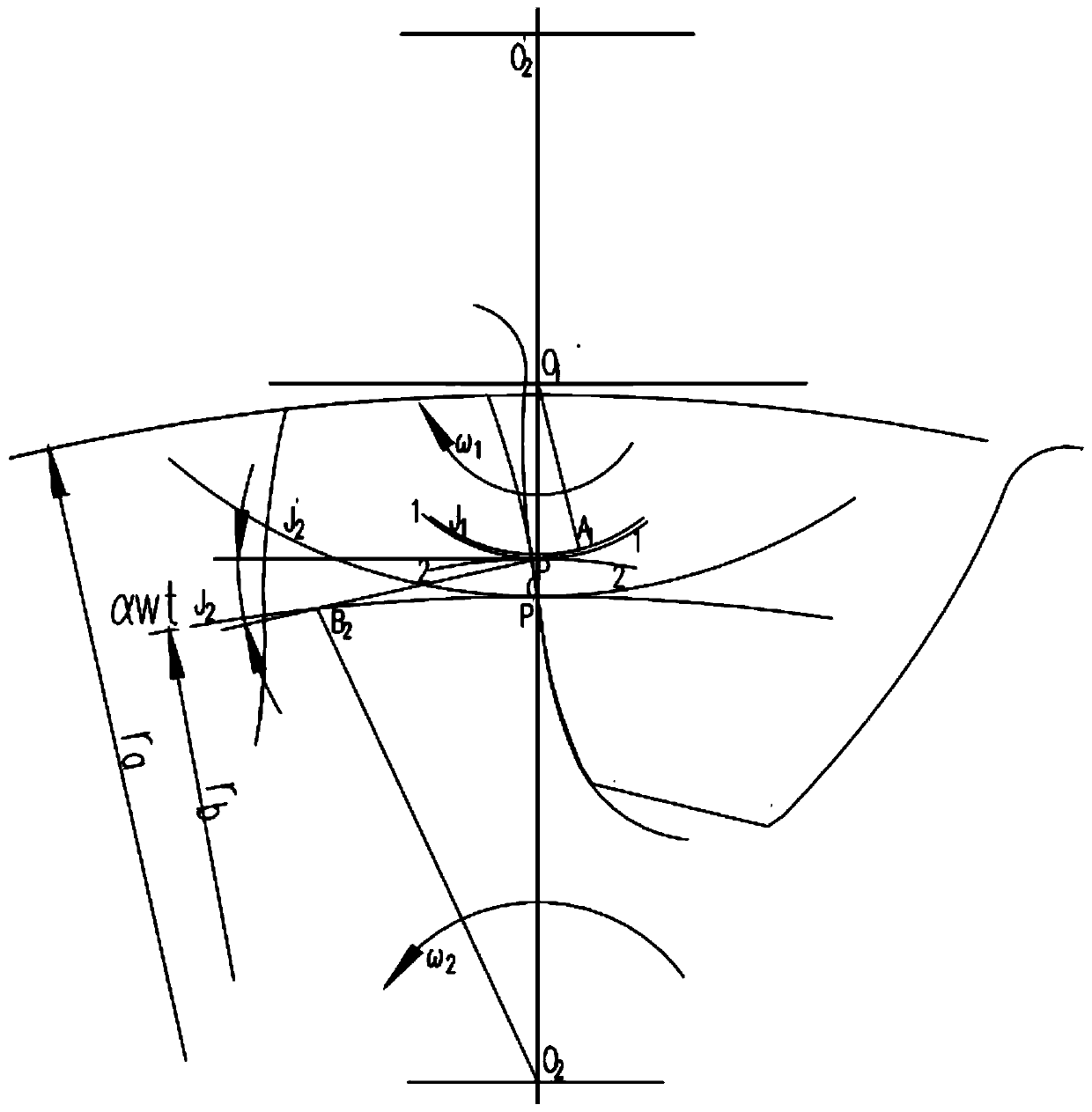

[0034] Such as Figure 1 to Figure 7 As shown, the acquisition method of the present invention includes the following steps:

[0035] 1): Based on the base circle of the gear, the function relationship of the reverse involute is obtained;

[0036] It is known that when the hob or slotting tool is cutting outside the base circle, the occurrence line of the involute is formed along the base circle, and when the hob or slotting tool extends into the base circle, the The direction of the starting point changes, take the starting point as the tangent line of the base circle, connect the starting point and the center of the base circle and extend it, it can be proved that the connecting line and the tangent line are perpendicular to each other, forming a plane Cartesian coordinate system, let the tangent line be the x line, connect The center line is the y line, and the origin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com