Involute gear hob of asymmetric tooth profile with equal modulus

A technology of involute gears and asymmetric teeth, which is applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

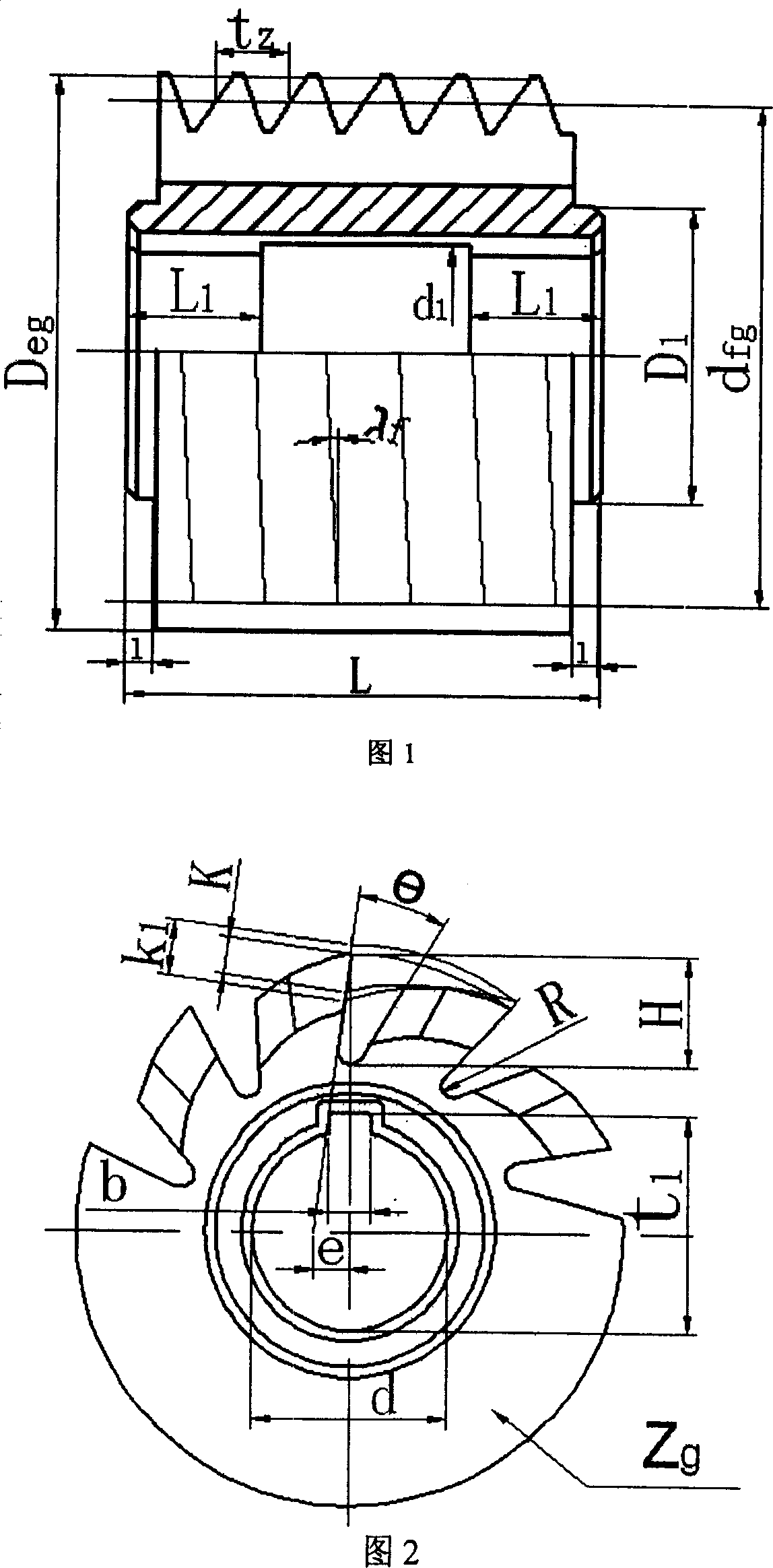

[0038] In Figure 1, firstly, according to the parameters of the processed asymmetric gear, the basic size and normal tooth profile size of the hob are obtained, and then the axial tooth profile size t is calculated z , t z = t n / cosλ fg =10.210 / cos2.78°=10.222, sub-circle helix angle λ f ,λ f = sin -1 (nm n / d fg ) = sin -1 (1*3.25 / 66.85)=2.78°, where, d fg - Divide the circle diameter for the hob. Thus the axial dimension of the hob can be determined.

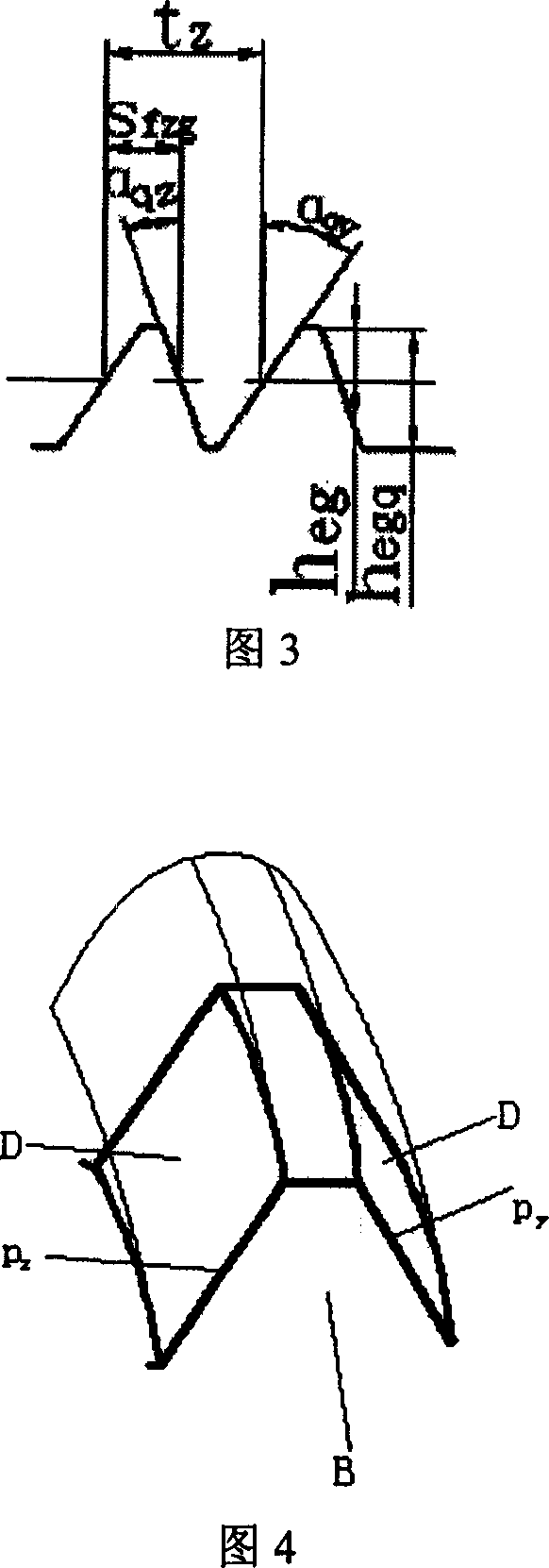

[0039] In Fig. 2, the first shovel amount K, K=πD eg tgα e / Z g =(3.14*75 / 10)tg(10°~12°)=4.15~5.01, take K=5; second shovel back quantity K 1 , K 1 =1.5K=1.5*5=7.5; take the flute angle θ=25°; chip flute depth H, H=h g +(K+K 1 ) / 2+1=7.6375+12.5 / 2+1=14.8875, take H=14.9; other pillow block or keyway size can be selected according to the modulus.

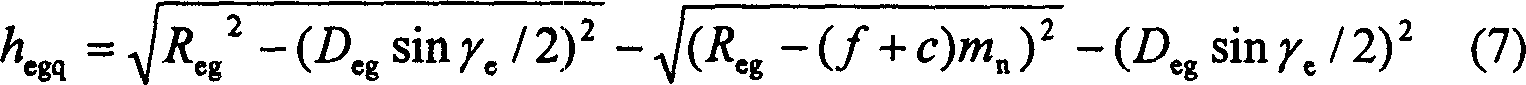

[0040] In Figure 3, from the previous formulas (5), (6), (7), (8): α qz =34.45°, α qy =20.19°, h eg = 3.61, h egq =7.72. S fzg = S fng / cosλ fg =5.1 / cos2.78°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com