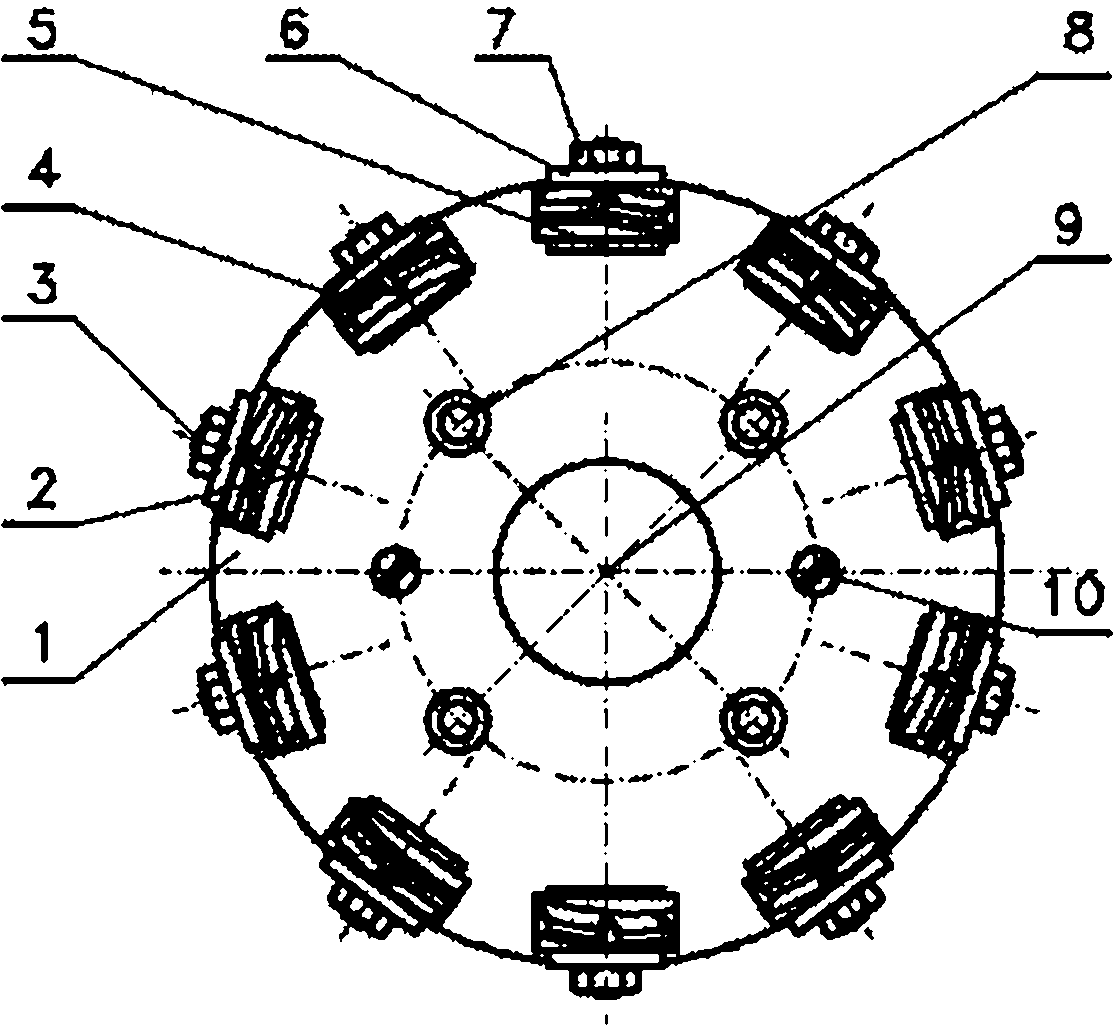

Method for processing cycloid-involute spiral bevel gears and solid cutter

A technology of a spiral bevel gear and a processing method, which is applied to components with teeth, metal processing equipment, gear teeth manufacturing tools, etc., can solve the problems of difficult processing, complex structure of the cutter head and spindle, and poor rigidity of the double cutter head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

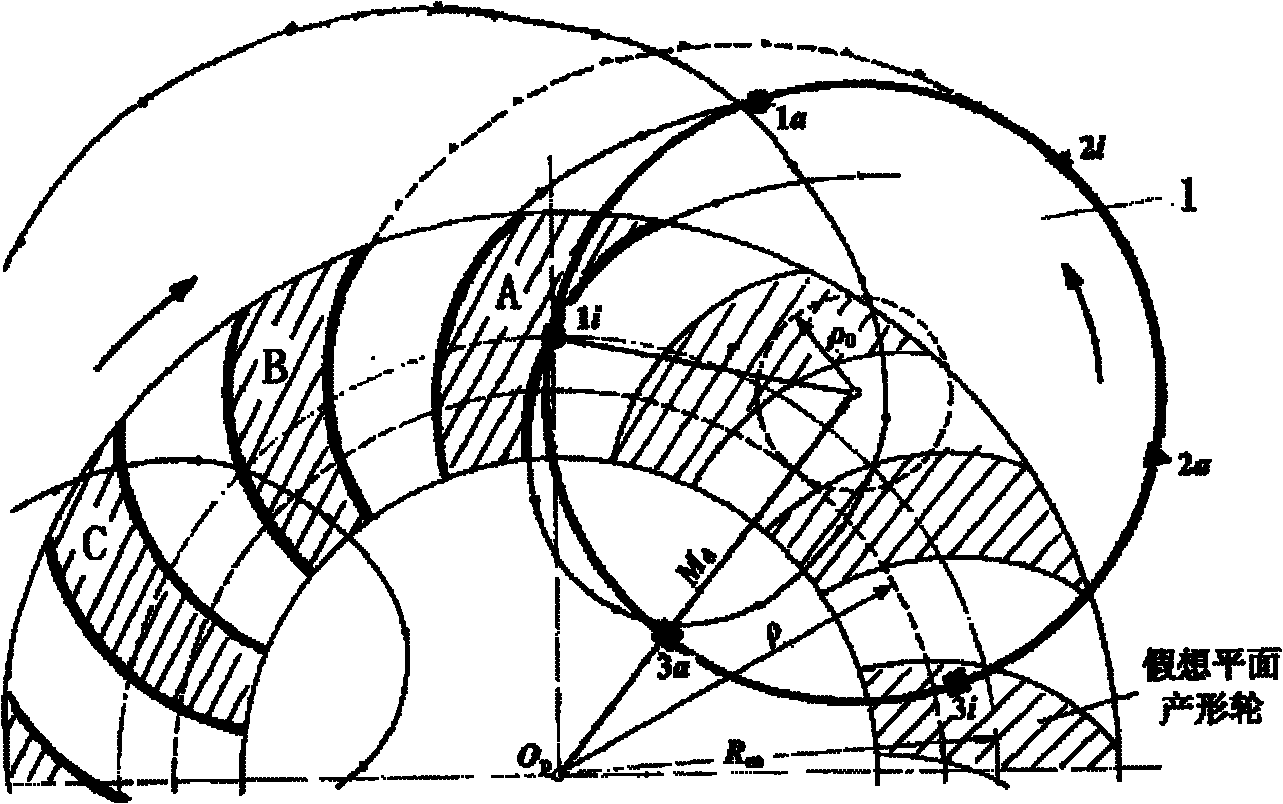

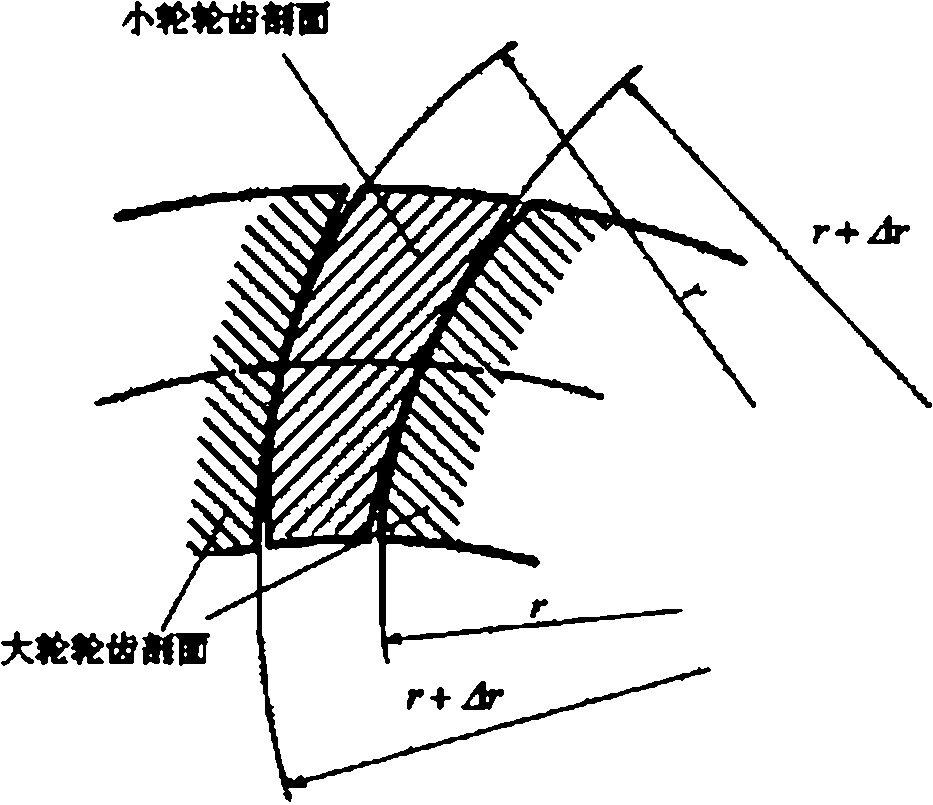

Method used

Image

Examples

Embodiment approach

[0076] As a preferred embodiment, the actual parameters of the cycloid-involute spiral bevel gear are:

[0077]

[0078]

[0079] The processing parameters of the large wheel are determined according to the helix angle of the midpoint of the convex surface of the large wheel is ψ:

[0080] N C = N sin Γ = 54.7448

[0081]

[0082] S = A 2 + r C 2 - 2 A r C sin ( ψ - v ) = 316.97 mm

[0083]

[0084] q=ψ+η=61.3152°

[0085] The helix angle of the concave surface of the big wheel is:

[0086] R = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com