Involute gear with concave and convex ring surfaces and method for designing and machining involute gear

A technology of involute gears and design methods, which is applied in the direction of belts/chains/gears, gear teeth, mechanical equipment, etc., can solve the problems of reduced load capacity, unstable transmission ratio, increased transmission error, etc., and achieve low processing costs , Improving the smoothness of motion and the effect of high tooth surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, the present invention is described in further detail:

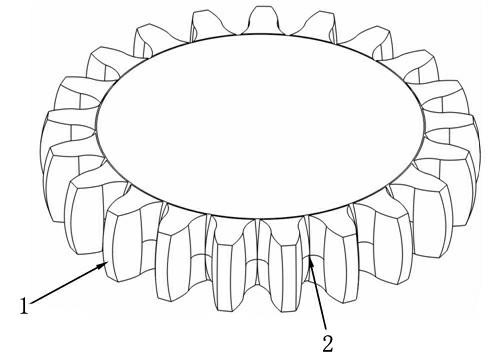

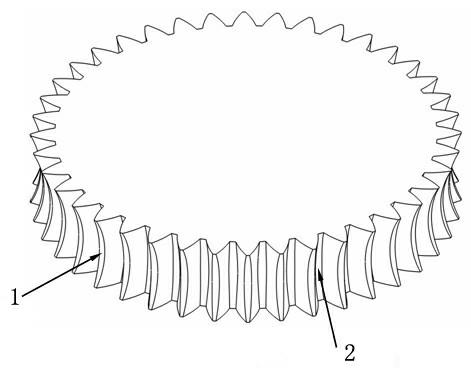

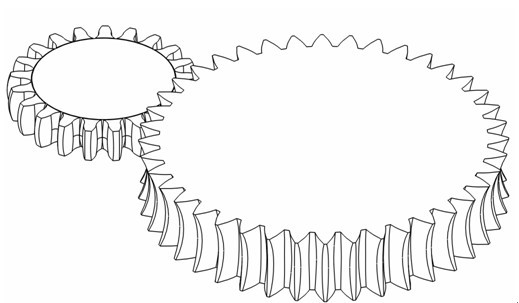

[0040] Such as figure 1 , 2 Shown: A toroidal involute gear is divided into two structural forms: convex toroidal involute gear and concave toroidal involute gear, which is characterized in that the curved surface of the tooth top and the curved surface of the dedendum are convex toroidal or concave toroidal A part of the surface, while the torus is formed by a circular arc rotating 360 degrees around the gear axis. The tooth profile curve of the end section of the gear tooth is an involute, which can realize a constant transmission ratio transmission. The tooth shape is distributed symmetrically about the midpoint of the tooth width. In each section along the tooth width direction, the thickness of the indexing circular tooth of the convex toroidal involute gear gradually decreases from the middle of the tooth width to both ends, while the thickness of the tooth to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com