Method for altering steel slag into grain slag

A technology of steel slag and water slag, which is applied in the field of harmless treatment of metallurgical waste steel slag, can solve the problems of high cost and increased process, and achieve the effects of low cost, improved reaction degree and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

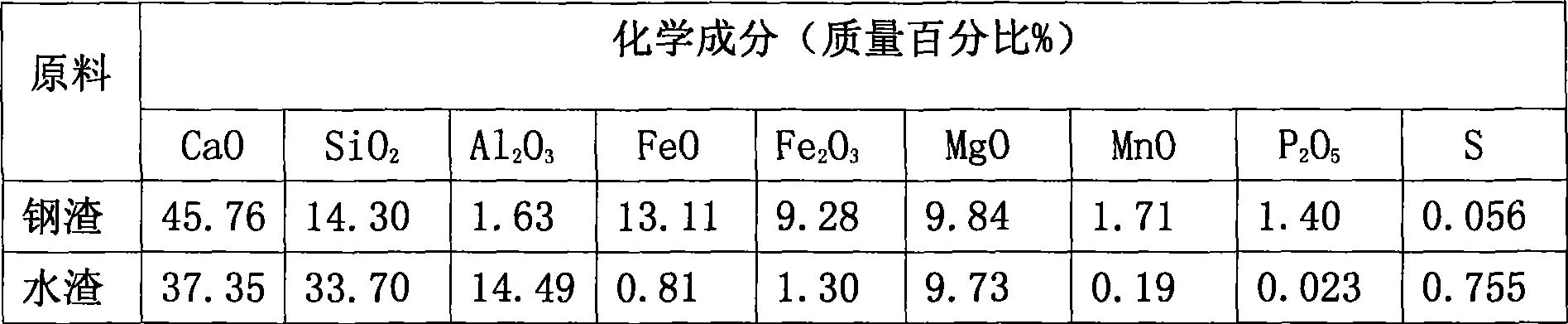

Method used

Image

Examples

Embodiment 2

[0024] Embodiment 2 of the method of the present invention: adding dry steel slag into liquid blast furnace slag at the slag ditch 1m away from the main iron ditch of the blast furnace. The dry powdered steel slag after iron selection is used above, and the particle size of the steel slag is less than 0.1mm. Steel slag is directly and evenly added to the liquid slag in the slag ditch through a feeding device protected by refractory materials. The weight of steel slag added is 25% of the weight of blast furnace slag, and water slag is obtained after cooling. Water slag was detected, and the stability was qualified.

[0025] Take 30 parts by weight of water slag after water quenching process, mix with 70 parts by weight of 325 cement, and add 25 parts by weight of cement at the same time to make a clean slurry test block. The 3-day compressive strength is 5.2MPa, the 7-day strength is 22.3MPa, and the 28-day strength is 40.3MPa. The stability is qualified. The stability is q...

Embodiment 3

[0026] Embodiment 3 of the method of the present invention: Add dry steel slag into liquid blast furnace slag at the slag ditch at a distance of 1.5m from the main iron ditch of the blast furnace. The dry powdered steel slag after iron selection is used above, and the particle size of the steel slag is less than 0.088mm. Steel slag is directly and evenly added to the liquid slag in the slag ditch through a feeding device protected by refractory materials. The weight of steel slag added is the weight of blast furnace slag, and water slag is obtained after cooling. Water slag was detected, and the stability was qualified.

[0027] Take 30 parts by weight of water slag after water quenching process, mix with 70 parts by weight of 325 cement, and add 25 parts by weight of cement at the same time to make a clean slurry test block. The 3-day compressive strength is 18.0MPa, the 7-day strength is 28.6MPa, and the 28-day strength is 53.7MPa. The stability is qualified.

Embodiment 4

[0028] Embodiment 4 of the method of the present invention: Add dry steel slag into liquid blast furnace slag at the slag ditch at a distance of 4.5m from the main iron ditch of the blast furnace. The dry powdered steel slag after iron selection is used above, and the particle size of the steel slag is less than 1 mm. Steel slag is directly and evenly added to the liquid slag in the slag ditch through a feeding device protected by refractory materials. The weight of steel slag added is 70% of the weight of blast furnace slag, and water slag is obtained after cooling. Water slag was detected, and the stability was qualified.

[0029] Take 30 parts by weight of water slag after water quenching process, mix with 70 parts by weight of 325 cement, and add 25 parts by weight of cement at the same time to make a clean slurry test block. The 3-day compressive strength is 18.0MPa, the 7-day strength is 22.5MPa, and the 28-day strength is 53.7MPa. The stability is qualified.

[0030...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com