Supercavitation gas-liquid multi-phase water spray propeller

A water jet propulsion, vapor-liquid technology, applied in ship propulsion, propulsion components, ship components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

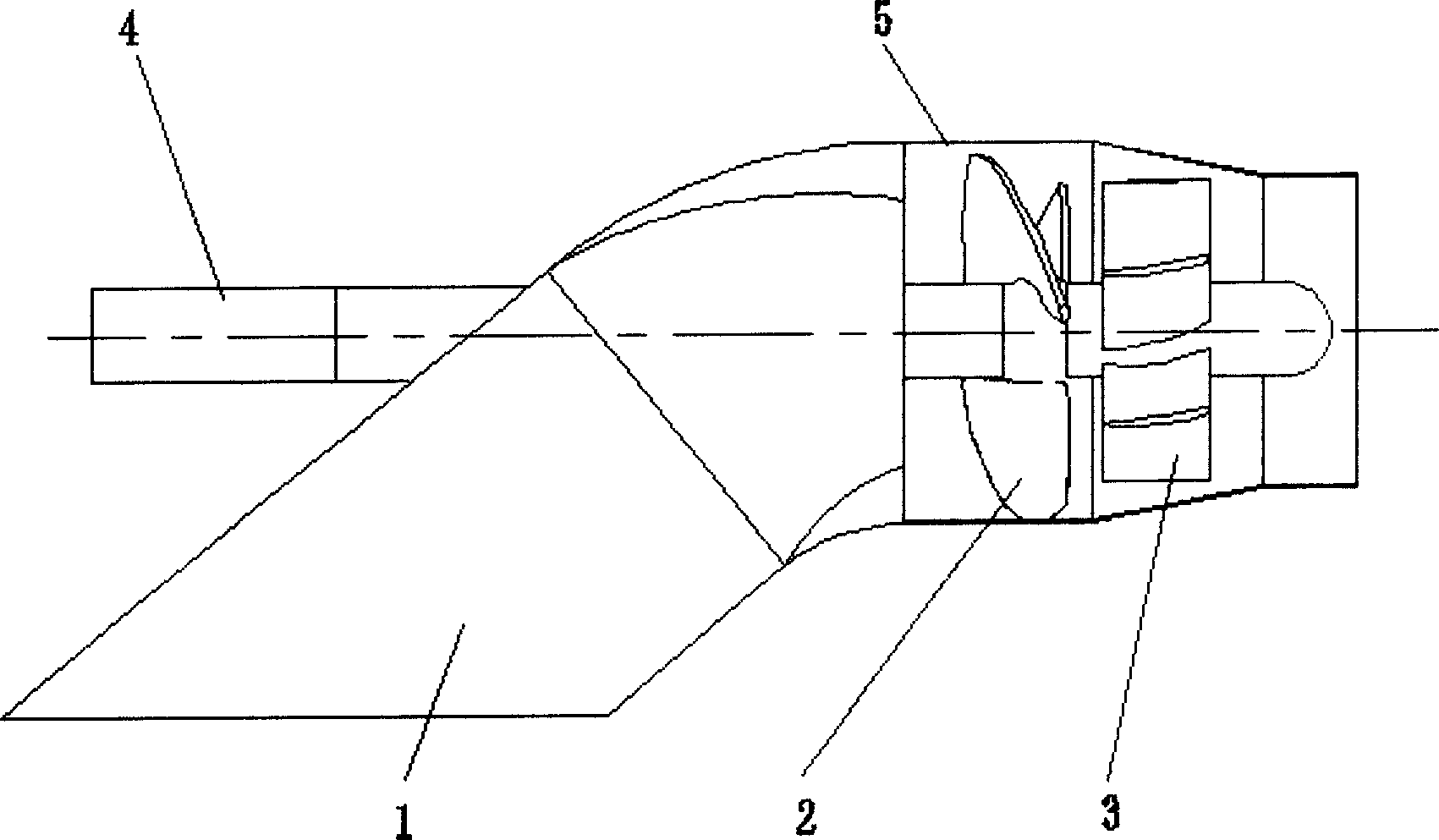

[0026] The same as the general water jet propeller, the supercavitation vapor-liquid multiphase water jet propeller drives the impeller of the pump stage to rotate through the motor, and converts the rotational mechanical energy into the mechanical energy of the liquid flow. Its basic structure is as follows: figure 1 As shown, it is composed of a water absorption chamber 1, a supercavitation impeller 2, a guide member 3, a shafting 4 and an impeller chamber 5.

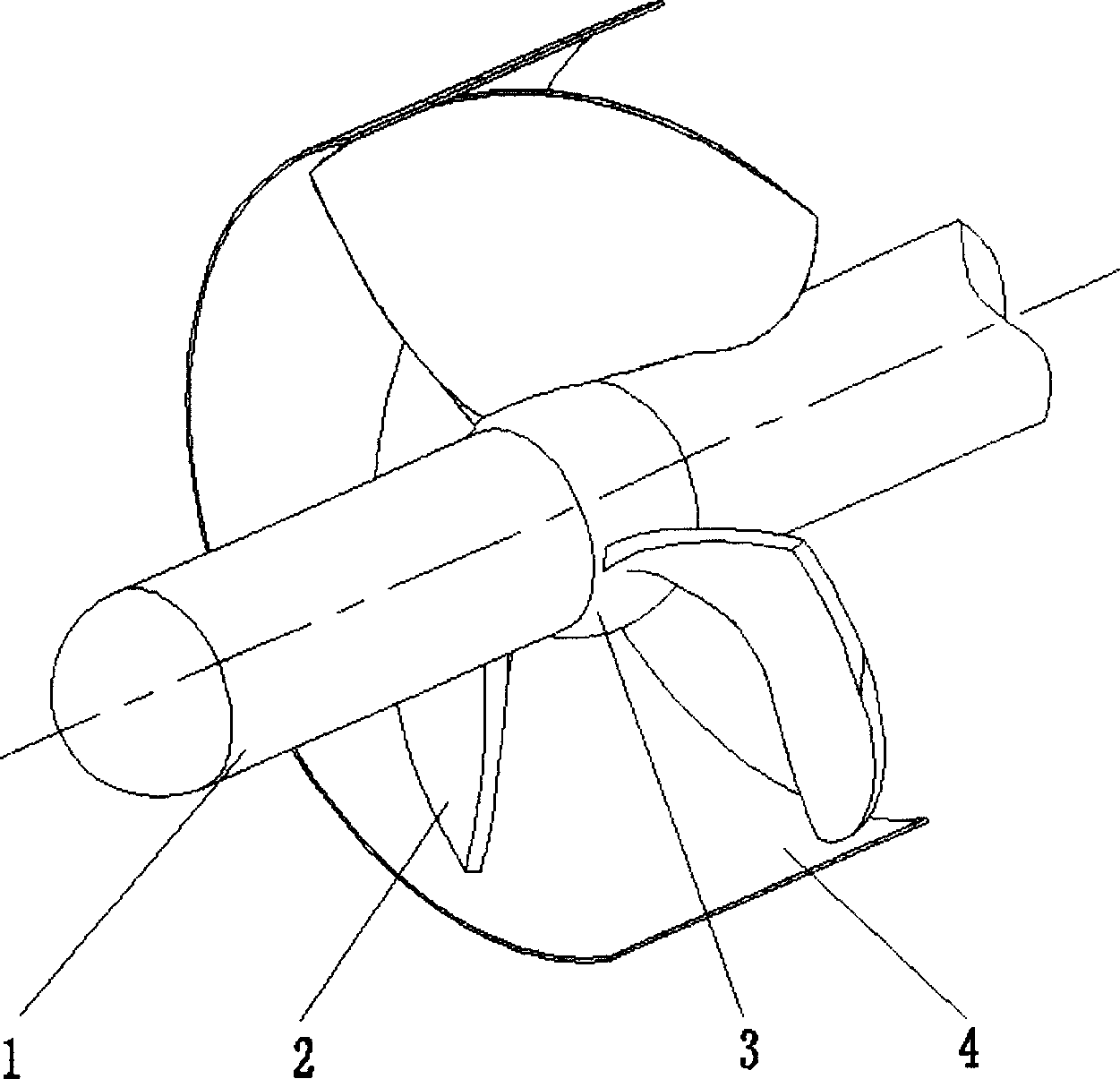

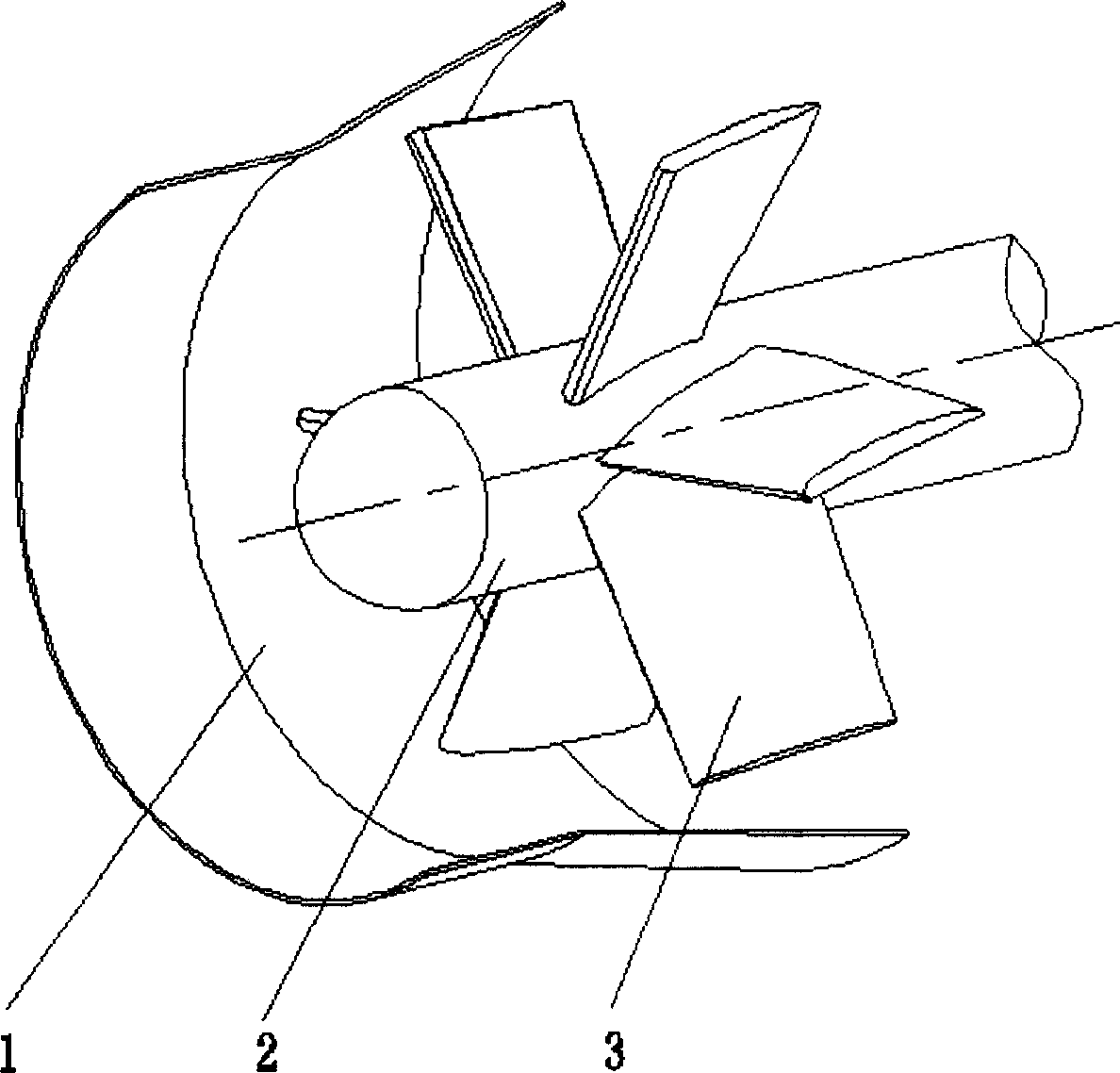

[0027] figure 2 It is the supercavitation impeller structure diagram, the main components are shaft 1, Tulin supercavitation blade 2, supercavitation impeller hub 3 and impeller chamber housing 4. image 3 It is a structural diagram of a kinetic energy converter, and its main components are a converter housing 1 , a shaft 2 and a converter blade 3 .

[0028] Under the rotation of the impeller, the liquid flow enters the supercavitation impeller through the water suction chamber. When the water body passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com