Production method of ultra-thin high-permeability oil filter paper

A production method and technology for oil filter paper, applied in the field of papermaking, can solve the problems of poor solvent resistance, water resistance, and folding resistance, and achieve the effects of good filtration and absorption performance, good acid and alkali resistance, and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

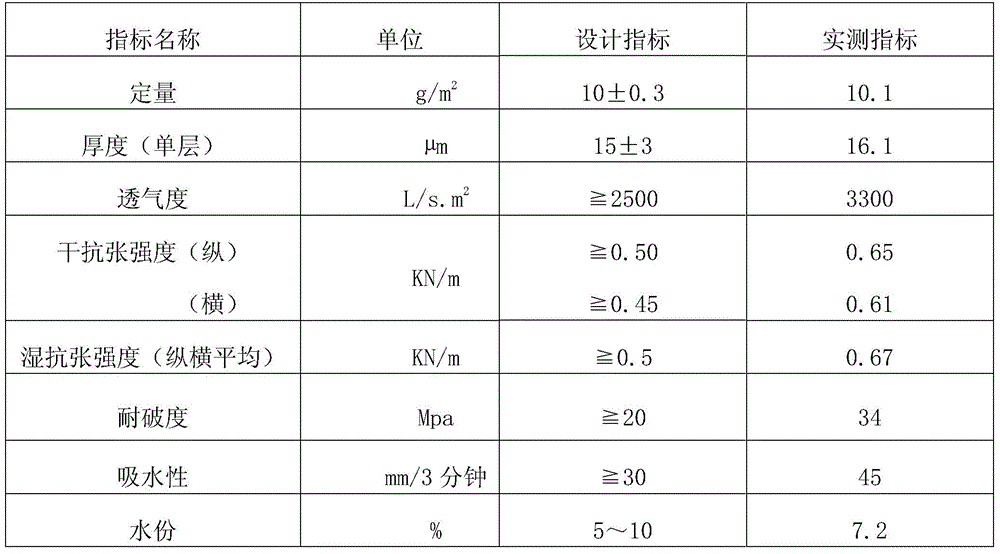

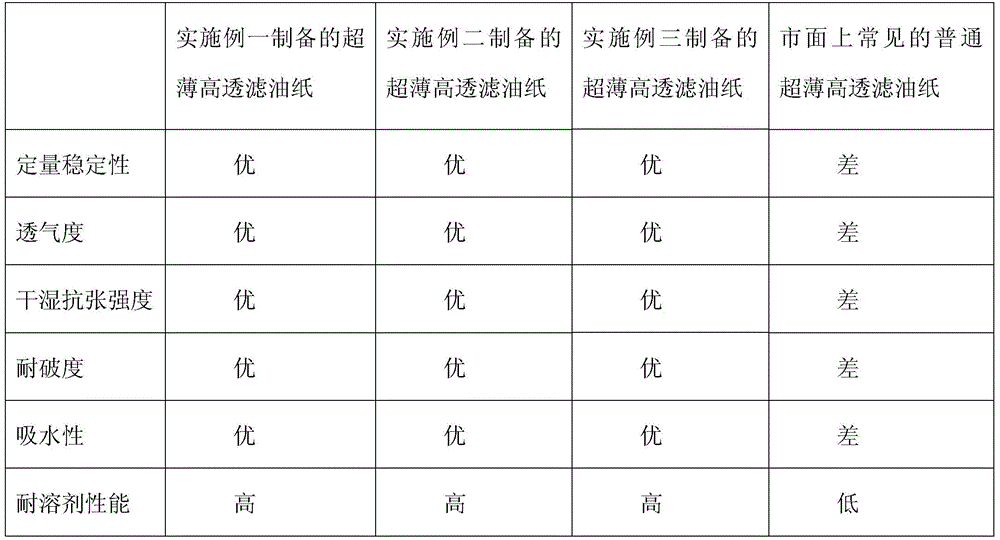

Examples

Embodiment 1

[0021] This ultra-thin high-permeability oil filter paper is made of the following raw material proportions by weight: 60 parts of hemp pulp, 30 parts of chemical fiber, 3 parts of wet strength agent, and 1 part of bamboo charcoal powder.

[0022] Preferably, hemp pulp is Manila hemp pulp.

[0023] Preferably, the chemical fibers are rich and strong fibers.

[0024] Preferably, the wet strength agent is polyester amide.

[0025] The production method of above-mentioned ultra-thin high permeability oil filter paper, comprises the steps:

[0026] The first step, beating treatment, first take the hemp pulp and add it to the Dutch beater, beat with a medium knife for 40 minutes, then add chemical fiber, beat with a light knife for 15 minutes, the beating concentration is 3.0%, and the wet weight is 20g. After the beating is completed Obtain the pulp, and then output the pulp to the stock tank;

[0027] The second step is to add additives, add wet strength agent to the pulp in t...

Embodiment 2

[0032] This ultra-thin high-permeability oil filter paper is made of the following raw material proportions by weight: 65 parts of hemp pulp, 35 parts of chemical fiber, 4 parts of wet strength agent, and 2 parts of bamboo charcoal powder.

[0033] Preferably, hemp pulp is Manila hemp pulp.

[0034] Preferably, the chemical fibers are rich and strong fibers.

[0035] Preferably, the wet strength agent is polyester amide.

[0036] The production method of above-mentioned ultra-thin high permeability oil filter paper, comprises the steps:

[0037] The first step, beating treatment, first take the hemp pulp and add it to the Dutch beater, beat with a medium knife for 40 minutes, then add chemical fiber, beat with a light knife for 15 minutes, the beating concentration is 3.2%, and the wet weight is 23g. After the beating is completed Obtain the pulp, and then output the pulp to the stock tank;

[0038] The second step is to add additives, add wet strength agent to the pulp in ...

Embodiment 3

[0043] This ultra-thin high-permeability oil filter paper is made of the following raw material proportions by weight: 70 parts of hemp pulp, 40 parts of chemical fiber, 5 parts of wet strength agent, and 3 parts of bamboo charcoal powder.

[0044] Preferably, hemp pulp is Manila hemp pulp.

[0045] Preferably, the chemical fibers are rich and strong fibers.

[0046] Preferably, the wet strength agent is polyester amide.

[0047] The production method of above-mentioned ultra-thin high permeability oil filter paper, comprises the steps:

[0048] The first step, beating treatment, first take hemp pulp and add it to the Dutch beater, beat with a medium knife for 40 minutes, then add chemical fiber, beat with a light knife for 15 minutes, the beating concentration is 3.5%, and the wet weight is 25g. After the beating is completed Obtain the pulp, and then output the pulp to the stock tank;

[0049] The second step is to add additives, add wet strength agent to the pulp in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com