Quantifying liquid-discharging structure with middle exhaust pipe

A technology of exhaust pipe and liquid discharge pipe, which is applied in fixed measuring chamber, chemical instrument and method, feeding device, etc., can solve the problems of inability to stably discharge liquid, inability to discharge gas from lower container, difficult to realize, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

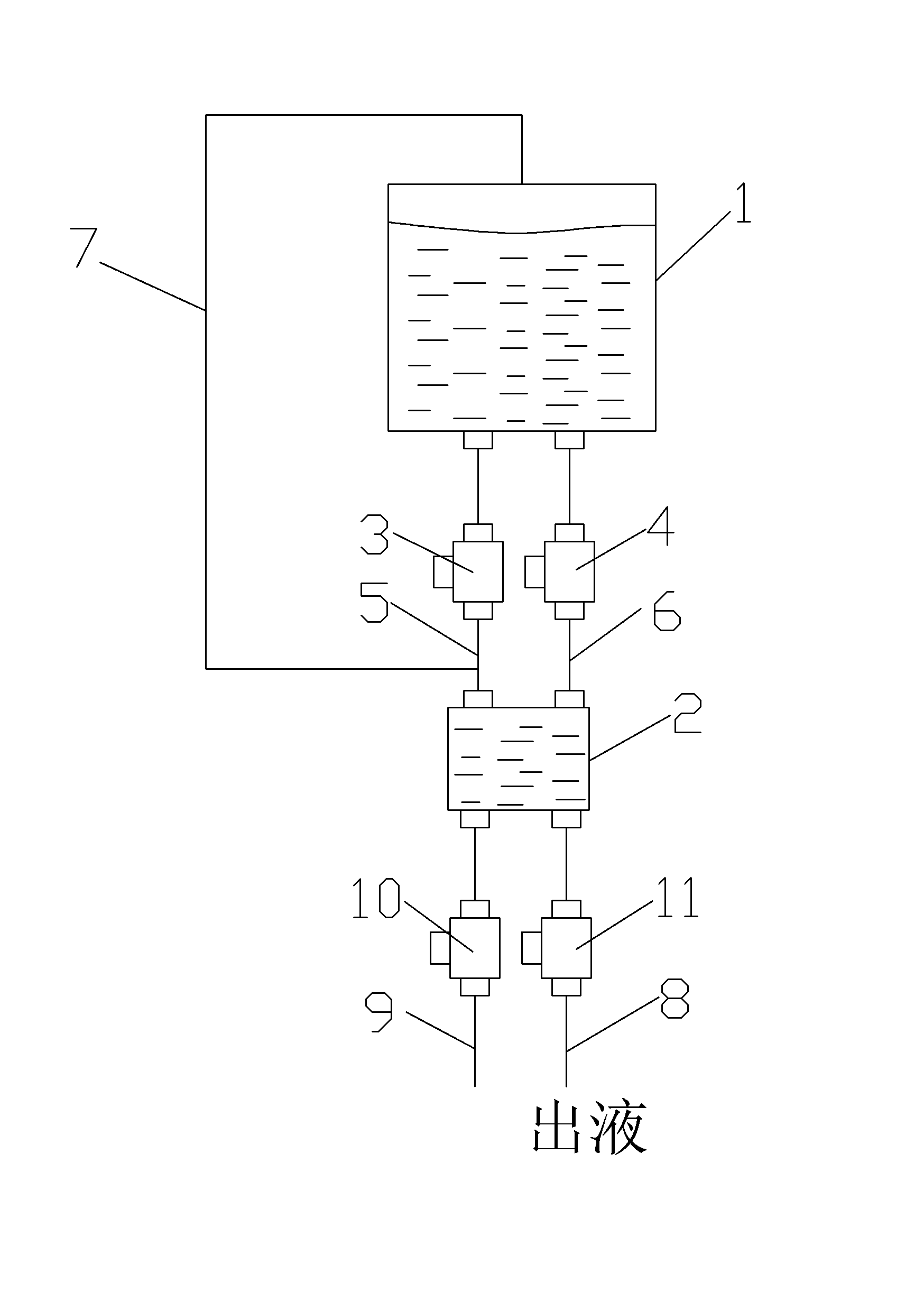

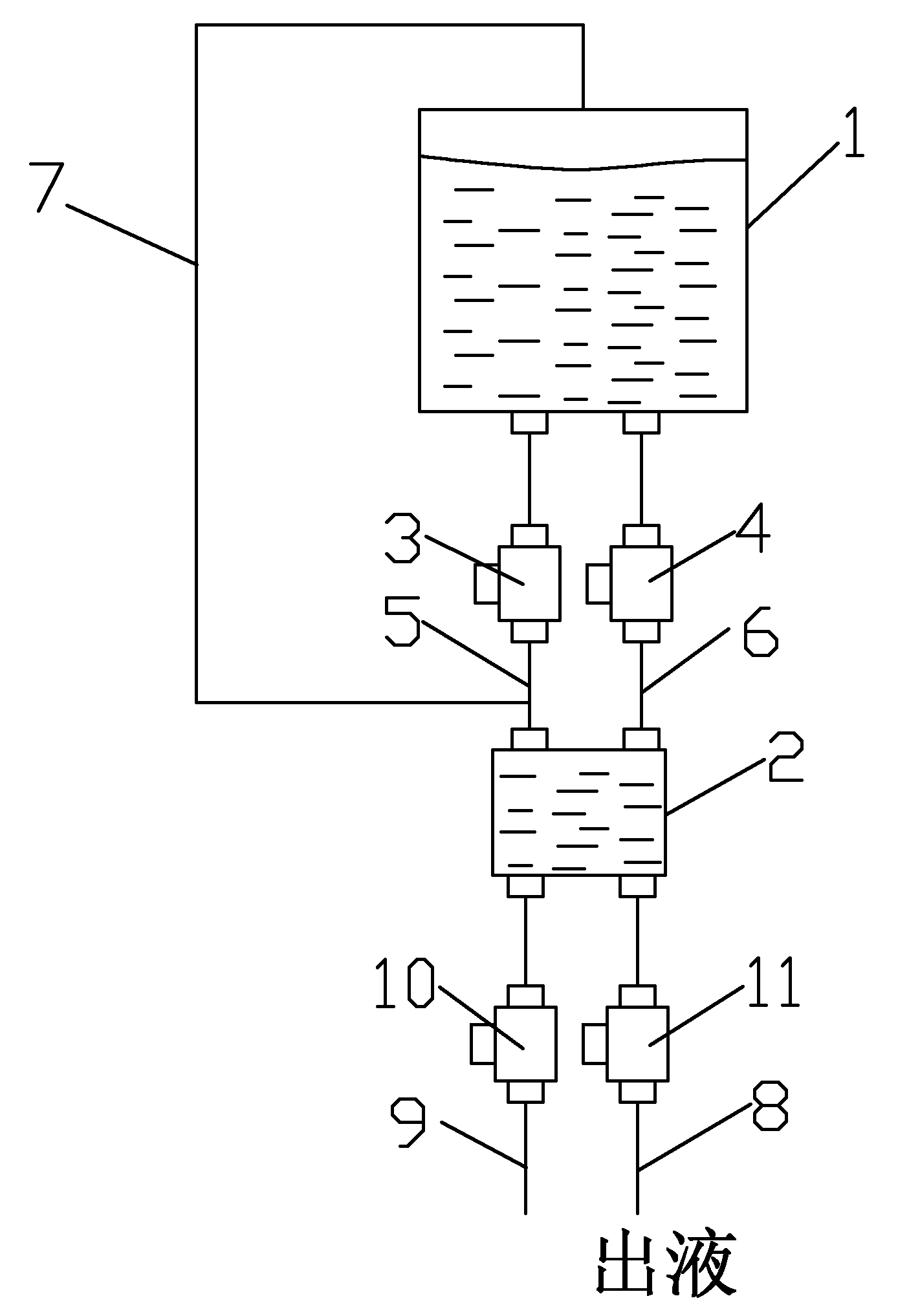

[0008] See figure 1 , which includes a solution tank 1, a quantitative tank 2, a liquid discharge pipe 8 and an air inlet pipe 9 below the quantitative tank 2, the bottom of the solution tank 1 is connected to the top of the quantitative tank 2 below it through two intermediate liquid pipes 5 and 6, and the two The middle liquid pipes 5 and 6 of the roots are equipped with middle solenoid valves 3 and 4, and the bottom of the quantitative irrigation 2 is respectively equipped with a liquid discharge pipe 8 and an air intake pipe 9, and the liquid discharge pipe 8 and the air intake pipe 9 are all equipped with a bottom electromagnetic valve 10. , 11, one end of the middle exhaust pipe 7 is connected to the middle liquid pipeline 5, and the other end is connected to the top of the solution tank 1, and one end of the middle exhaust pipe 7 is located between the middle solenoid valve 3 and the quantitative tank 2, and the middle solenoid valves 3, 4 All open and close simultaneou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com