Throttle valve system and working method thereof

A working method and throttle valve technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as circumvention, vortex, affecting fluid stability and continuity, etc., to reduce throttling loss and meet energy saving requirements The effect of emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

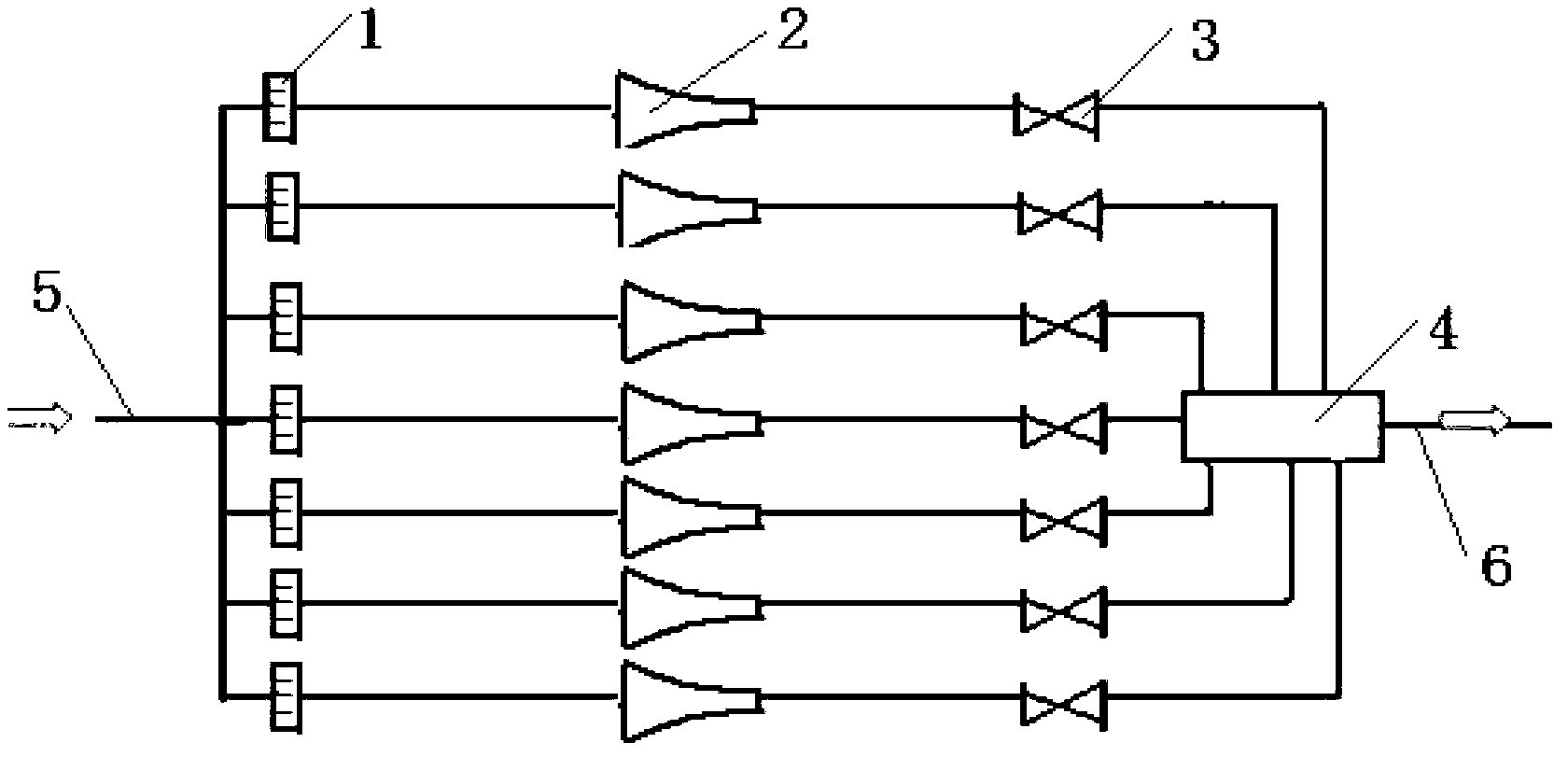

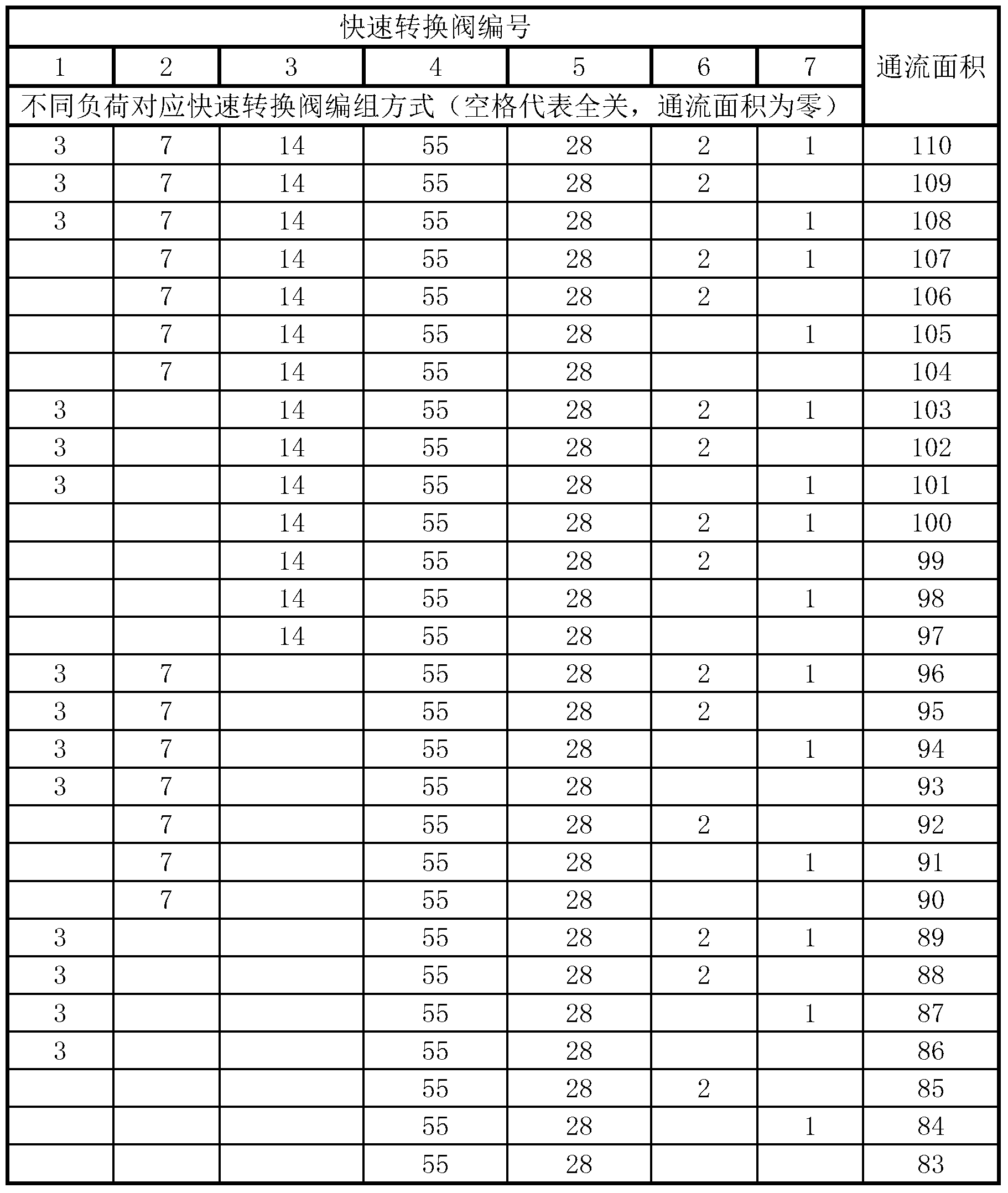

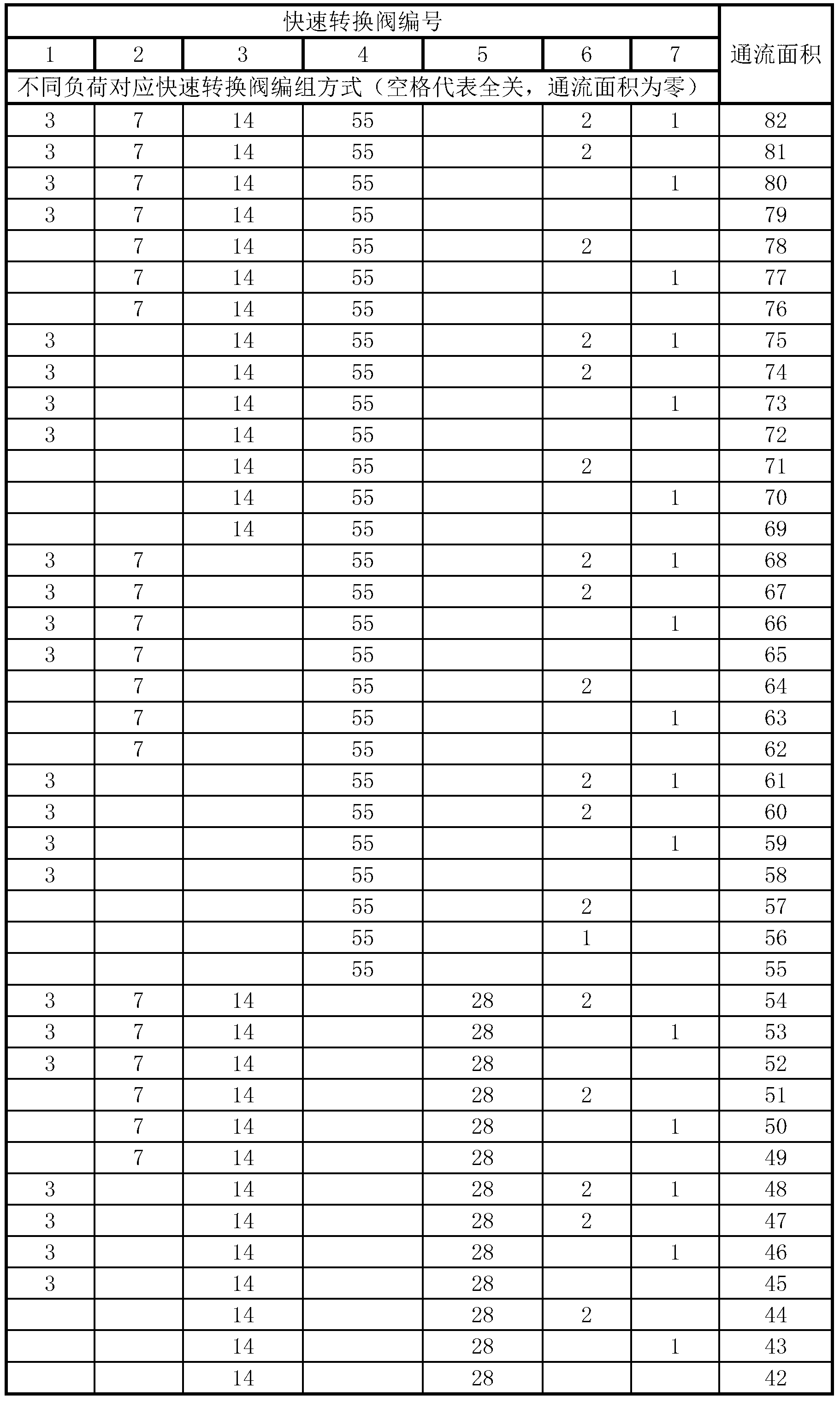

[0025] Such as figure 1 As shown, the present invention comprises 7 passages connected in parallel to the upstream straight pipe section 5, and its flow area is respectively 1%, 2%, 3%, 7%, 14%, 28%, 55%, and each passage includes successive connections The flow regulator 1, the flow nozzle 2 and the quick switching valve 3, and each quick switching valve 3 communicates with the downstream straight pipe section 6 through the buffer 4, and the quick switching valve 3 includes two states of fully open and fully closed.

[0026] A flow regulator 1 is used to reduce the length of the upstream straight pipe section 5 and make the fluid flow stably;

[0027] Flow nozzle 2, used to generate pressure difference and measure fluid flow;

[0028] Quick switching valve 3, which includes two states of fully open and fully closed, and these two states can be switched in a very short time;

[0029] The buffer 4 is capable of buffering pressure fluctuations caused by a 1% change in flow amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com