Patents

Literature

78results about How to "Small reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light Sources Adapted to Spectral Sensitivity of Diurnal Avians and Humans

ActiveUS20110228515A1Improve welfareImprove lifetime developmentElectrical apparatusAnimal housingLight-emitting diodeVisual perception

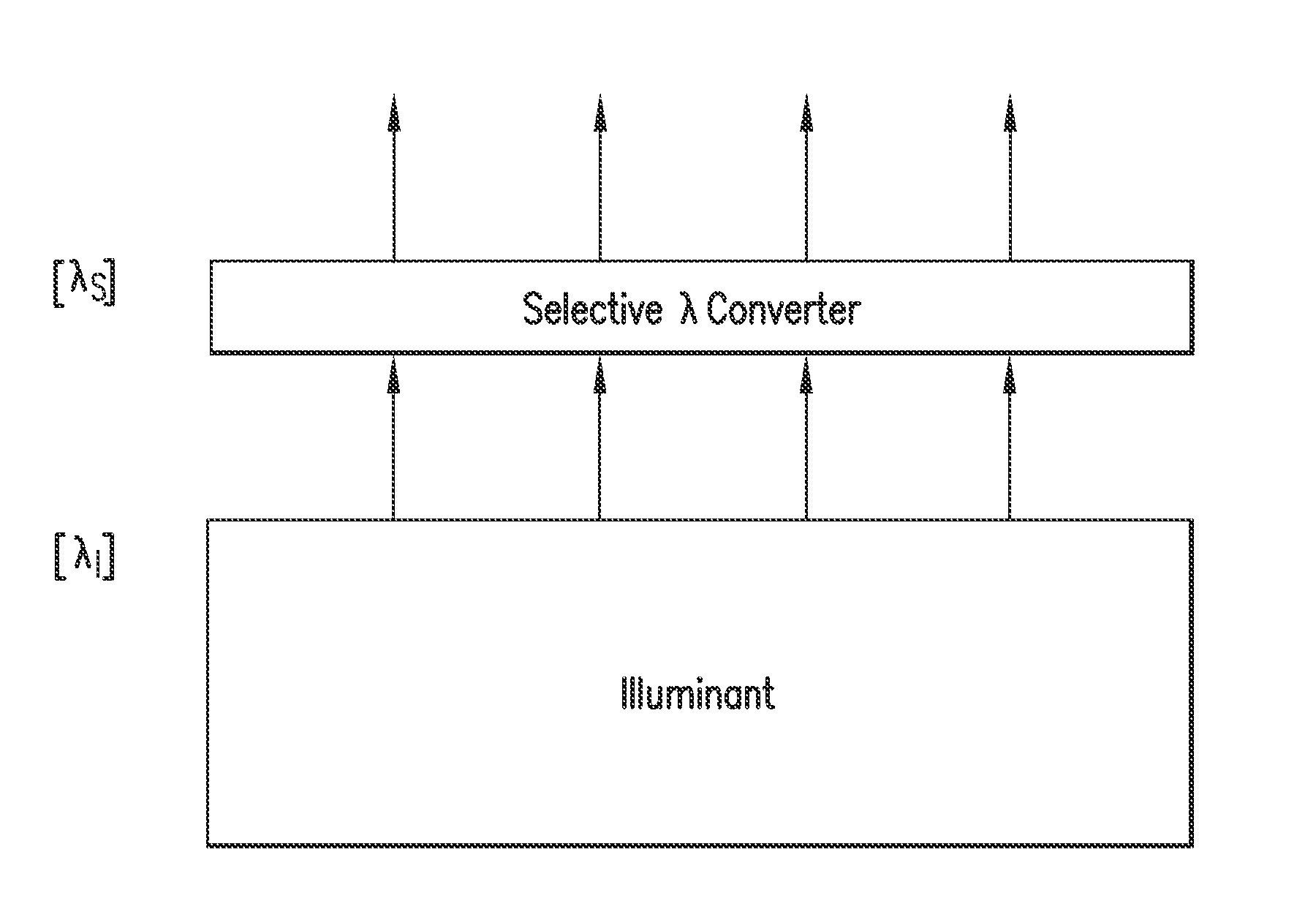

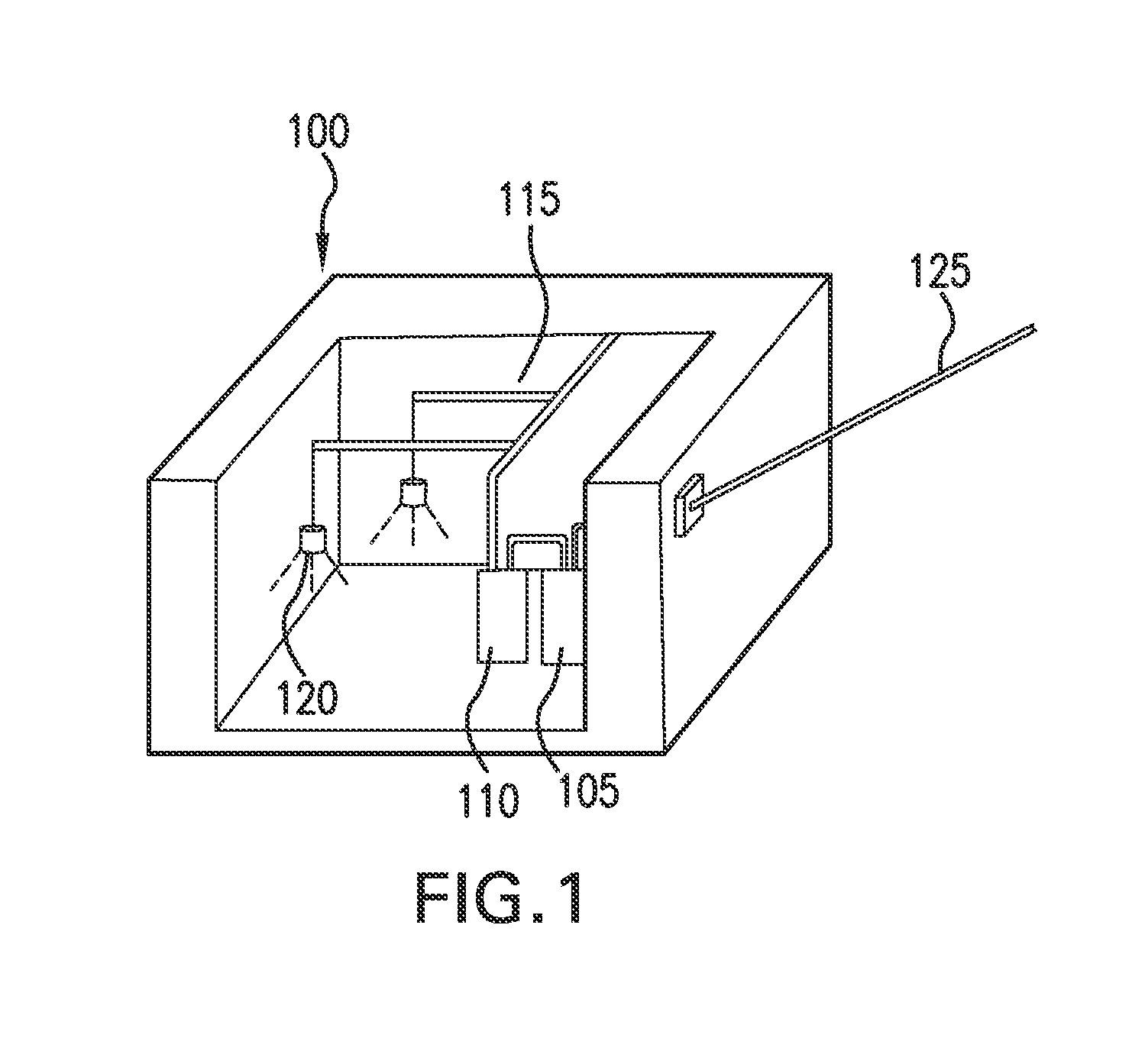

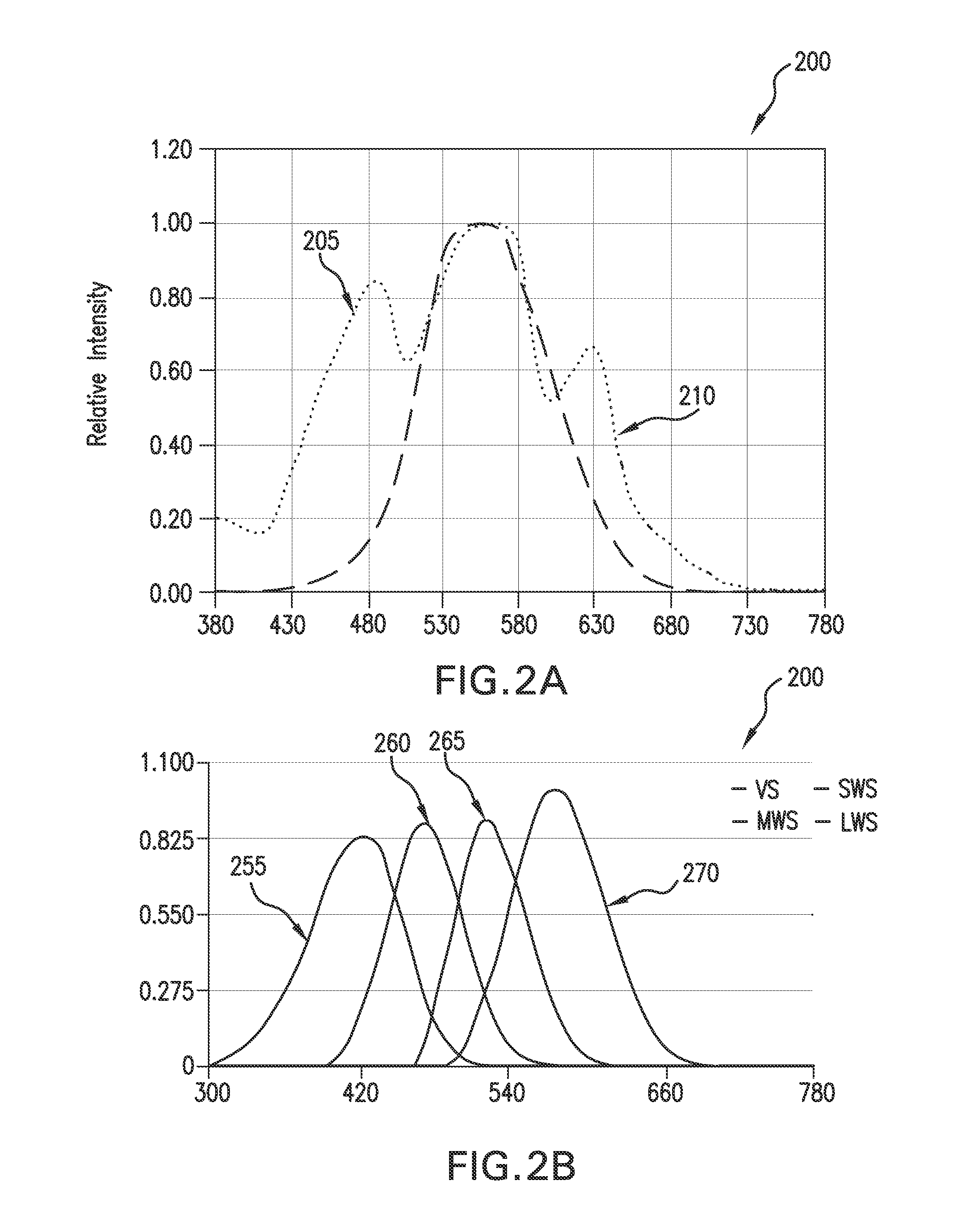

Various apparatus and associated methods involve a light source that provides light at wavelengths that substantially correlate to local maxima in the spectral sensitivity of a diurnal avian. In an illustrative example, the light source may output light primarily in wavelength bands that are not substantially absorbed by colored oil droplets and / or visual pigment in at least one type of cone in the eye of a diurnal avian. In some embodiments, the light source may include a light-emitting diode (LED) light source. Exemplary light sources may output spectral components to illuminate diurnal avians with local maxima of intensity at wavelengths that substantially correspond to local maxima in a spectral sensitivity visual response characteristic of the diurnal avians.

Owner:SIGNIFY NORTH AMERICA CORP

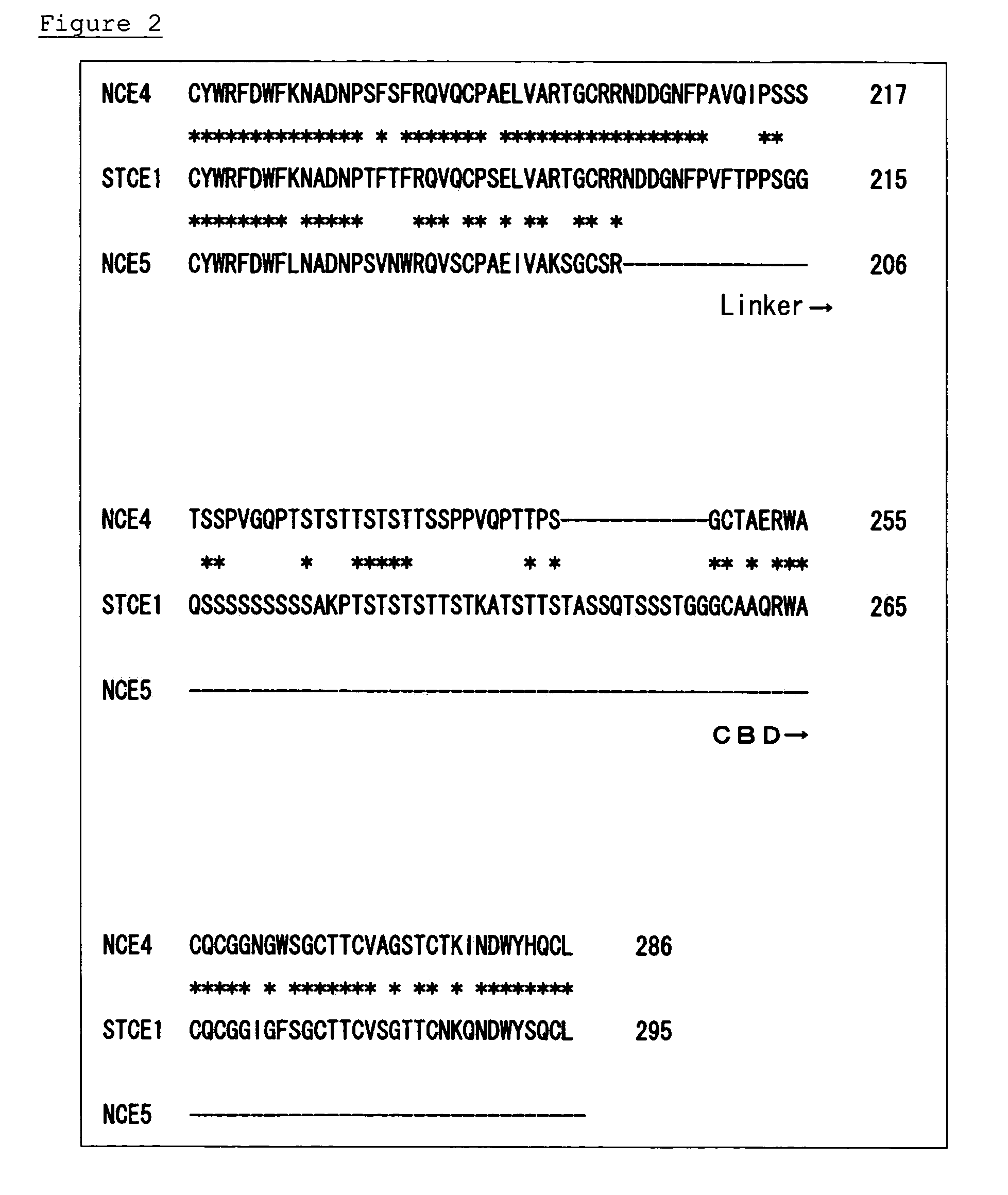

Surfactant tolerant cellulase and method for modification thereof

ActiveUS8569033B2Efficient productionReduce presenceSugar derivativesMicroorganismsNucleotideL-Pyroglutamic Acid

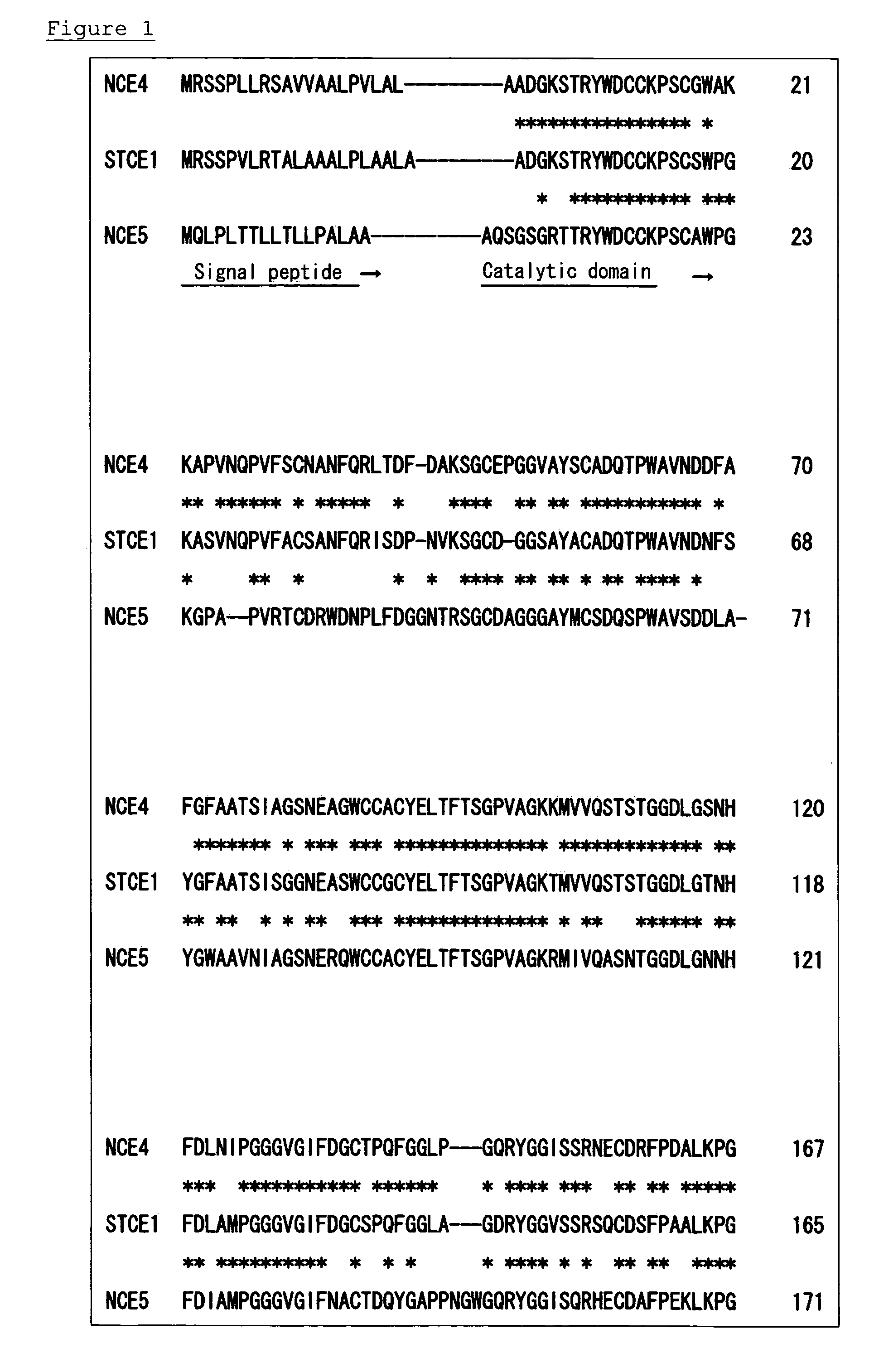

A method for suppressing a reduction in an endoglucanase activity in the presence of a surfactant, characterized by modifying a protein having the endoglucanase activity in which the N-terminus is an amino acid other than pyroglutamic acid, to a protein having the N-terminus of pyroglutamic acid, is disclosed. Further, a modified protein having an endoglucanase activity wherein the N-terminal amino acid is converted into pyroglutamic acid by an amino acid modification, a polynucleotide encoding the protein, an expression vector comprising the polynucleotide, a host cell transformed with the expression vector, and a process for producing the protein by cultivating the host cell, are disclosed.

Owner:MEIJI SEIKA KAISHA LTD

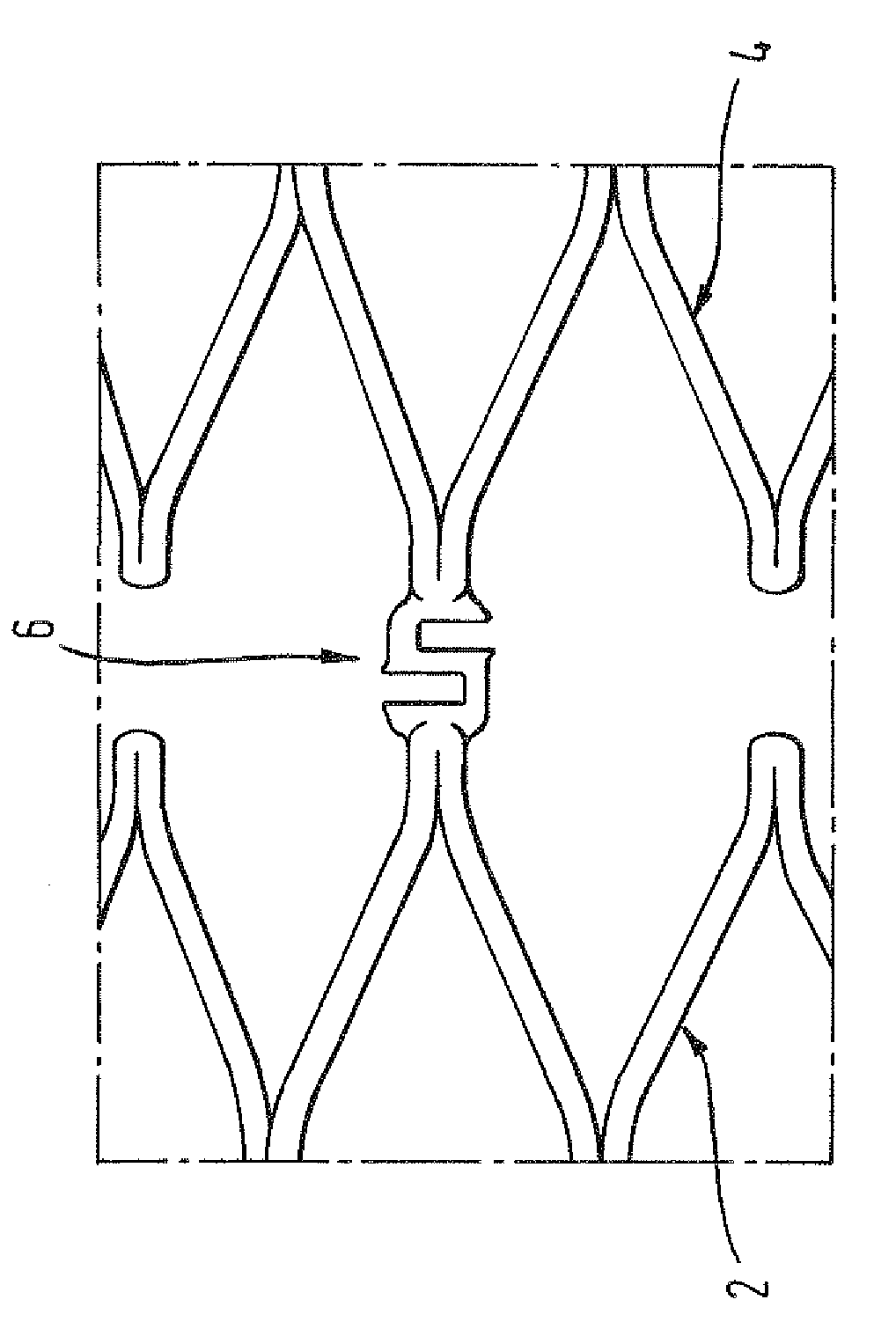

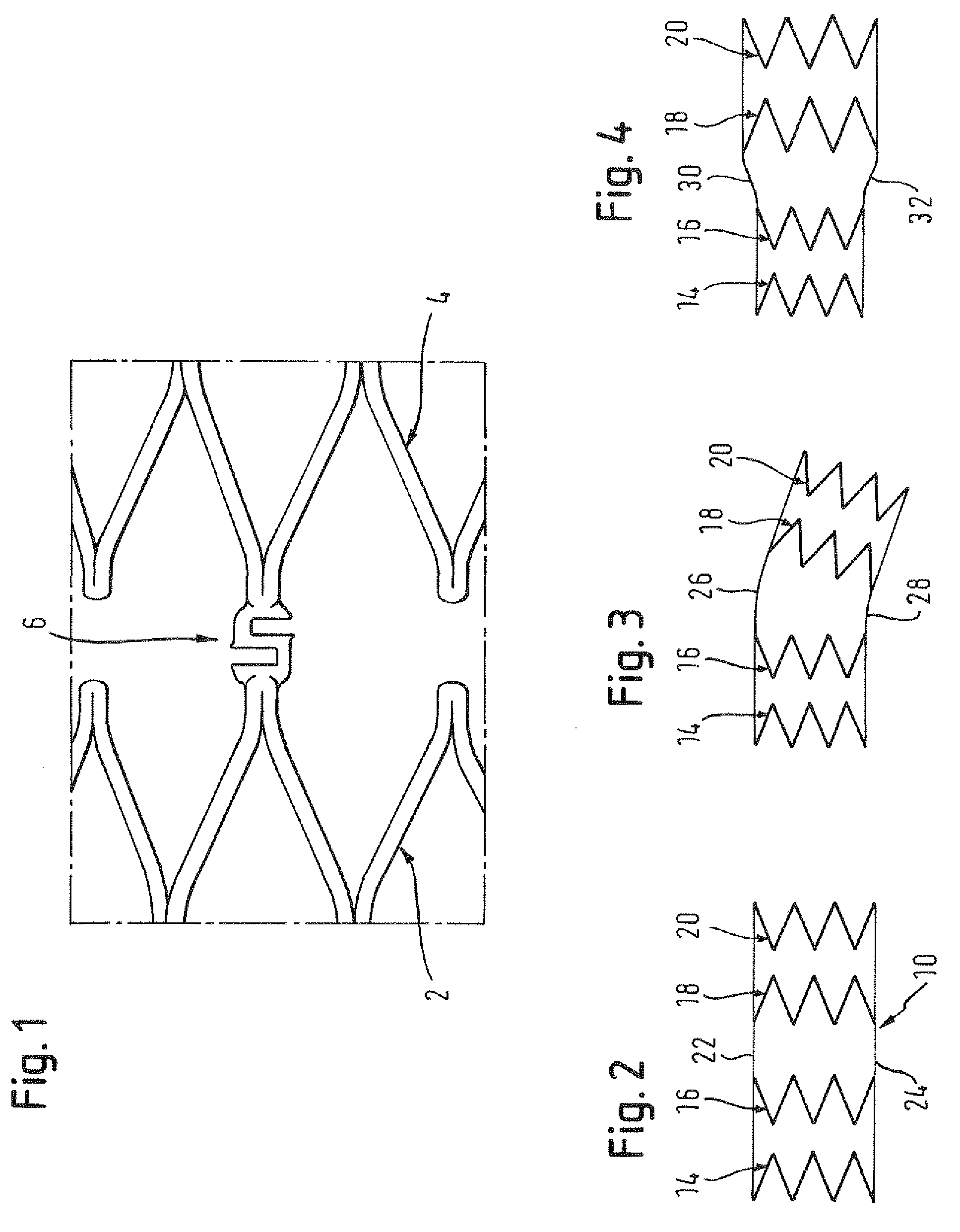

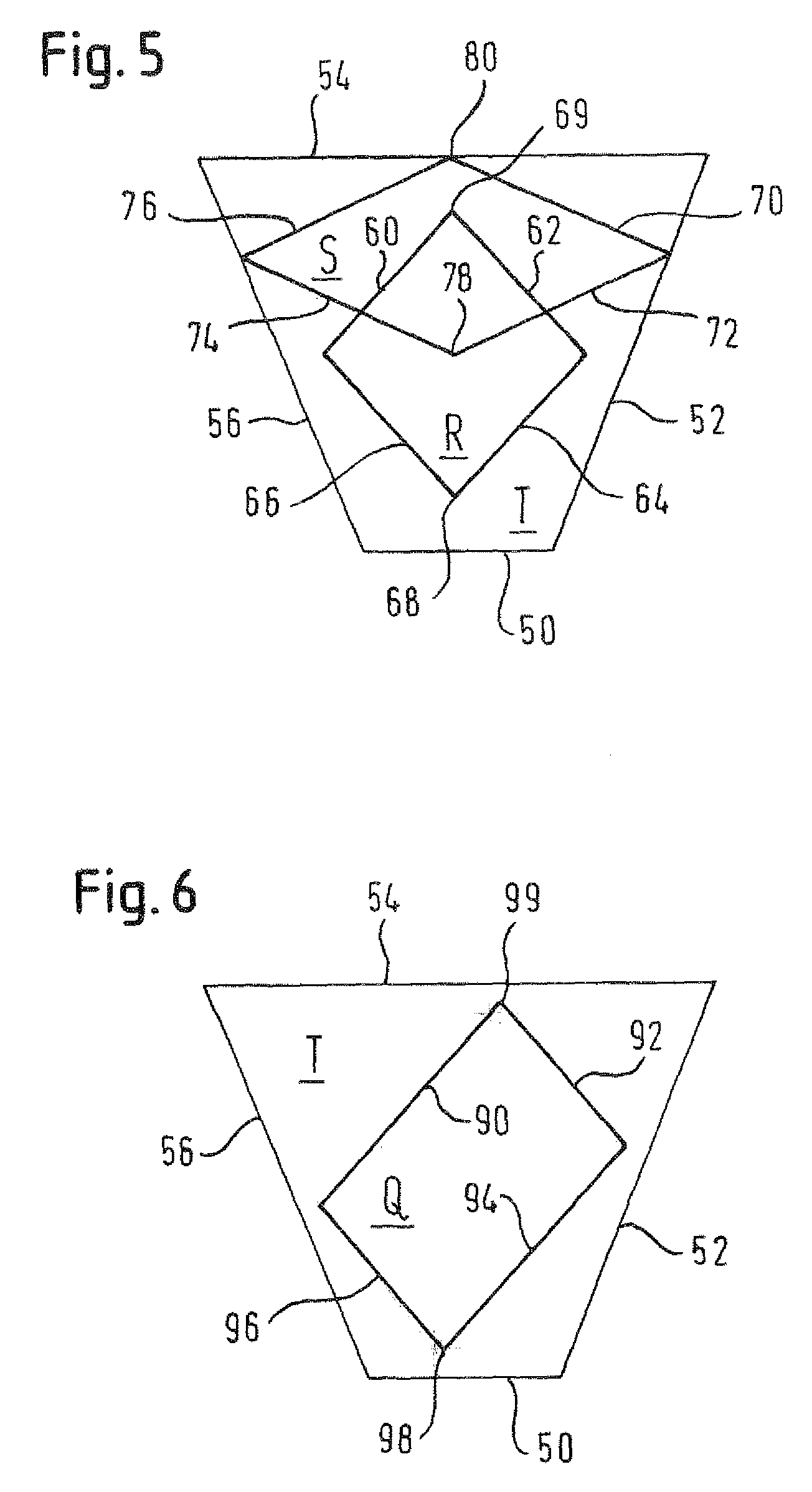

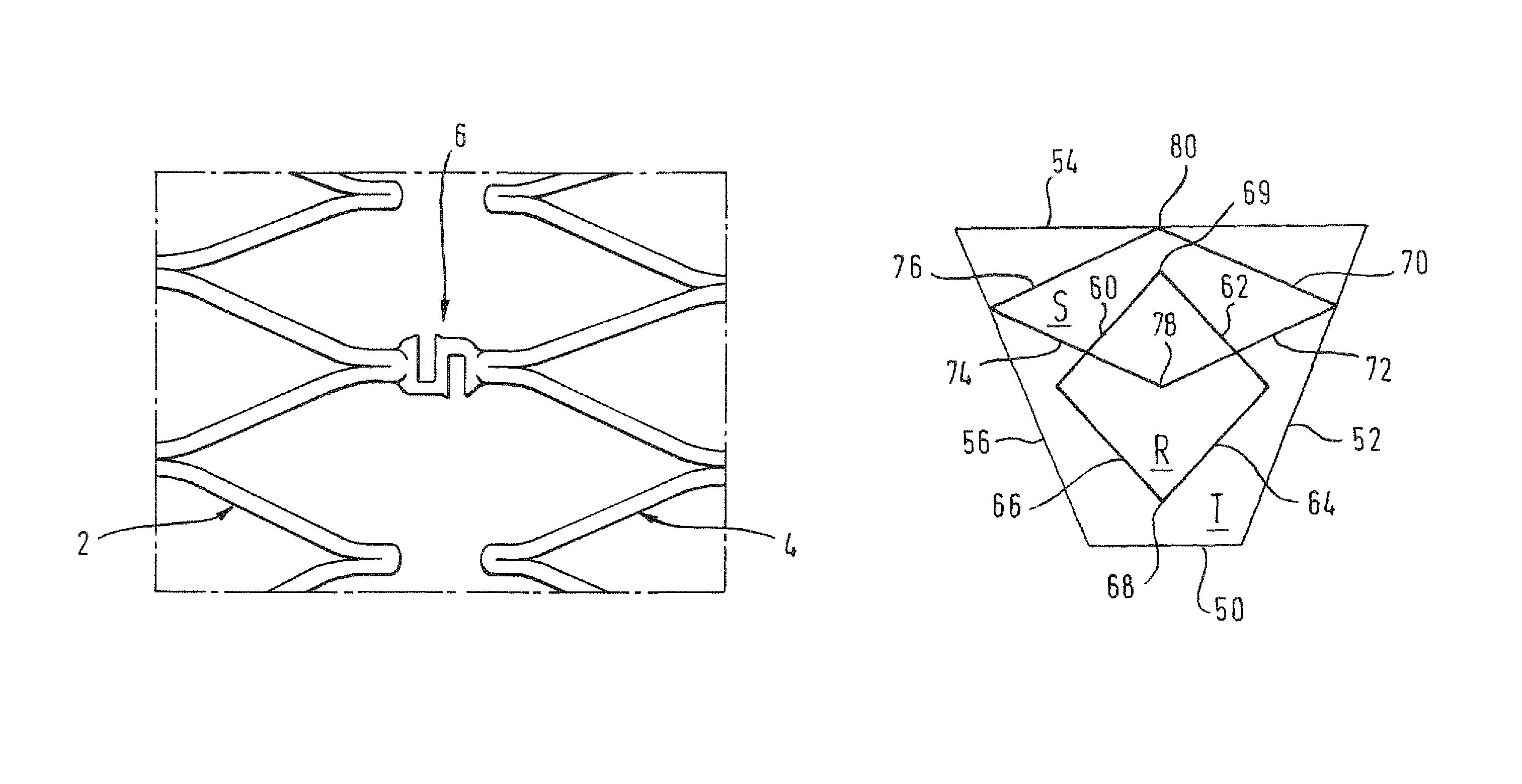

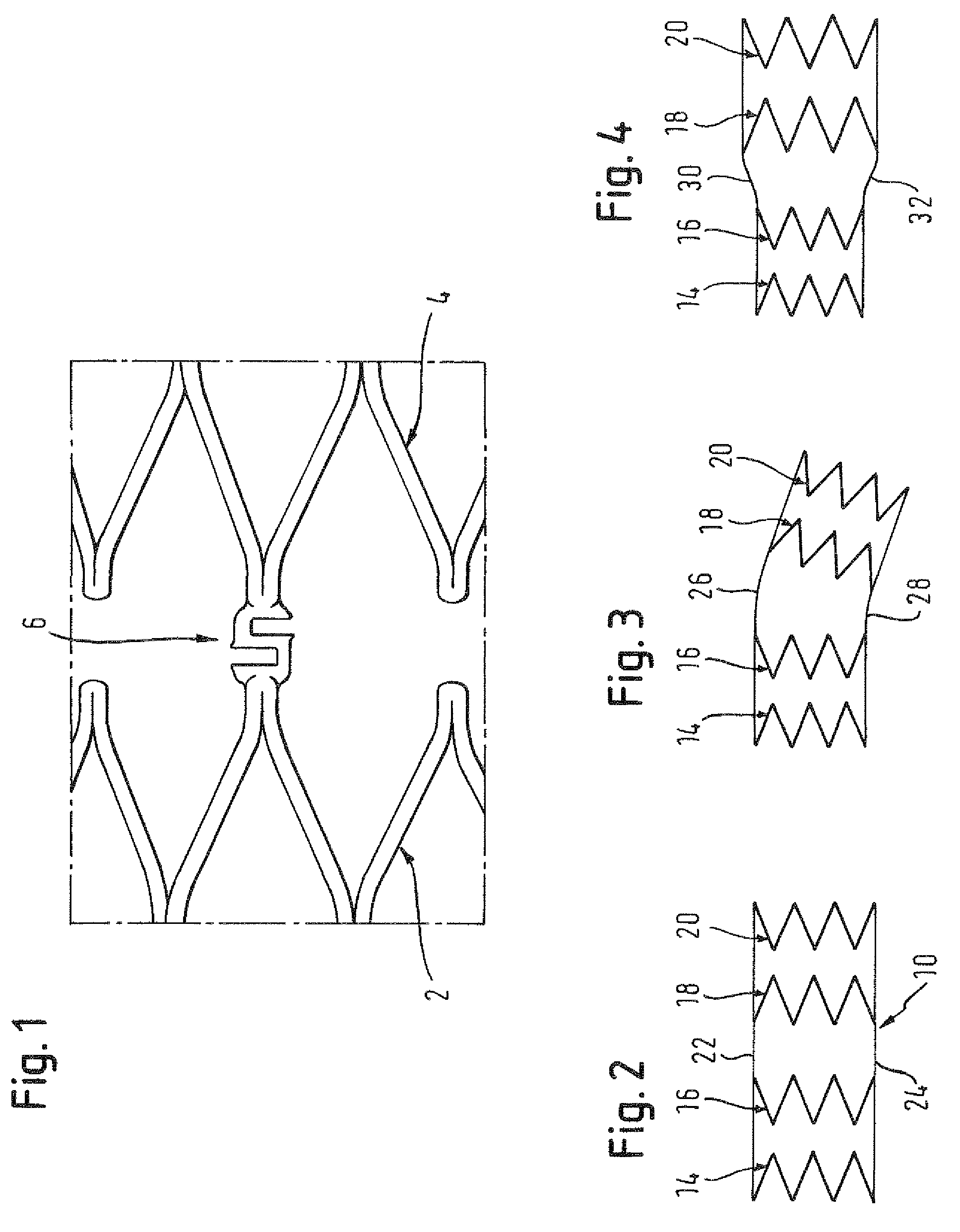

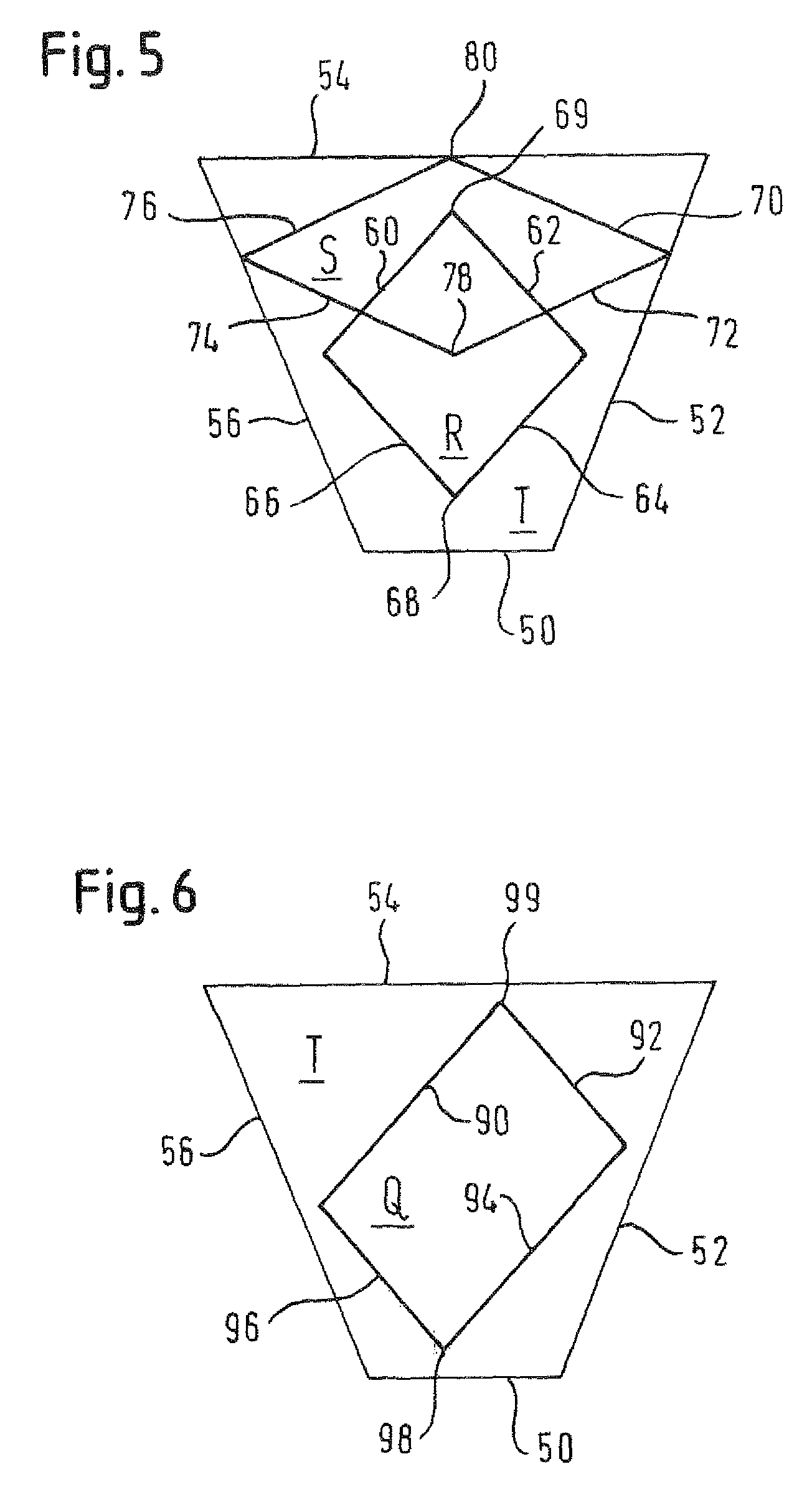

Stent

A radially expansible annular stent is disclosed. The stent comprises a plurality of stenting turns around a lumen centred on a longitudinal axis. Adjacent turns of the stent are joined by connector struts. The stent annulus has a wall thickness related to the material from which it is formed. The radial thickness of the connector struts is smaller than that of the stent annulus. A method of making such a stent is also disclosed. The method includes cutting the connector struts from a tubular workpiece with a laser beam. The laser beam is aimed so as to be offset from a longitudinal axis of the workpiece to provide the reduced radial thickness of the connector struts.

Owner:CR BARD INC

Stent

Owner:CR BARD INC

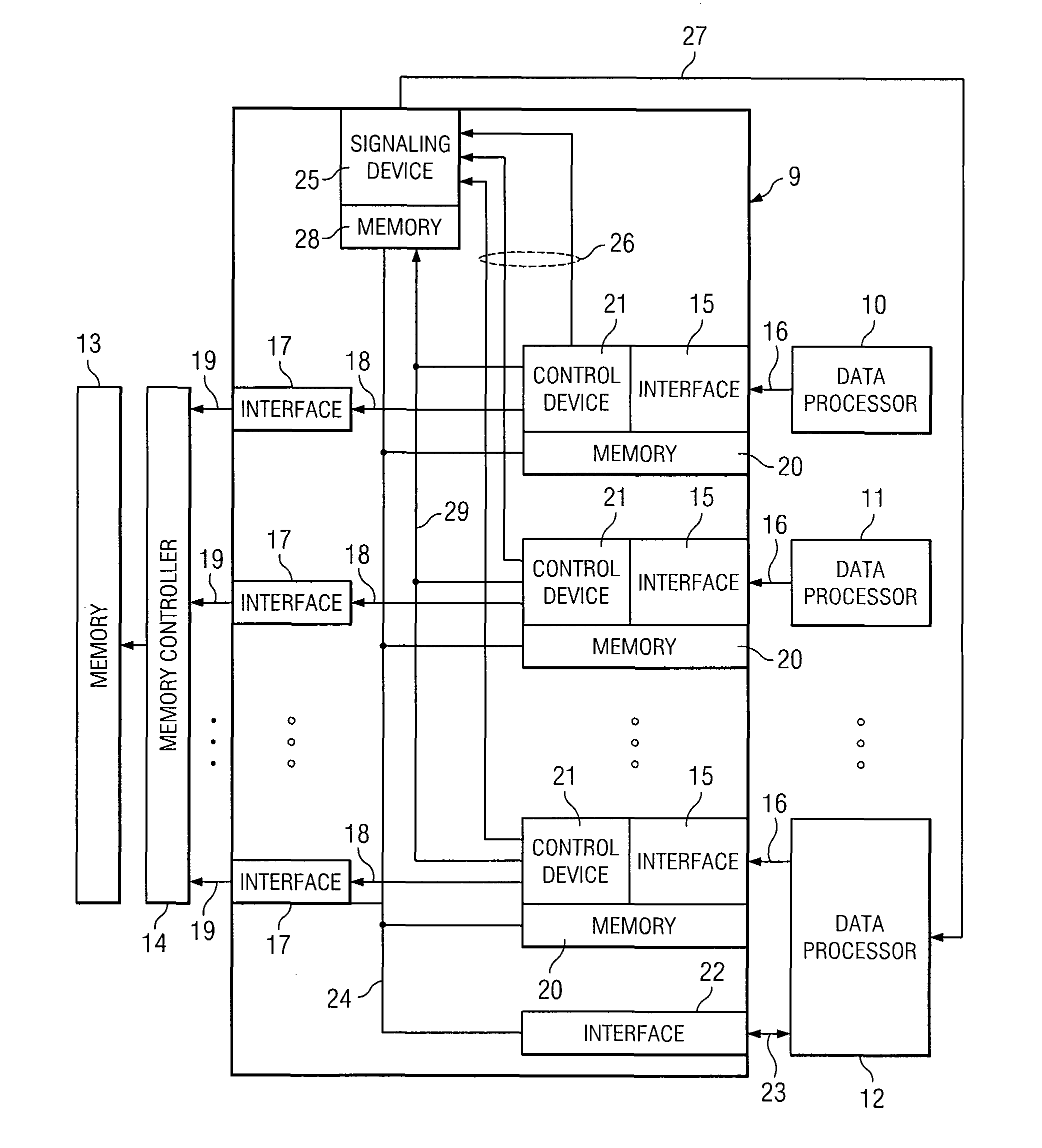

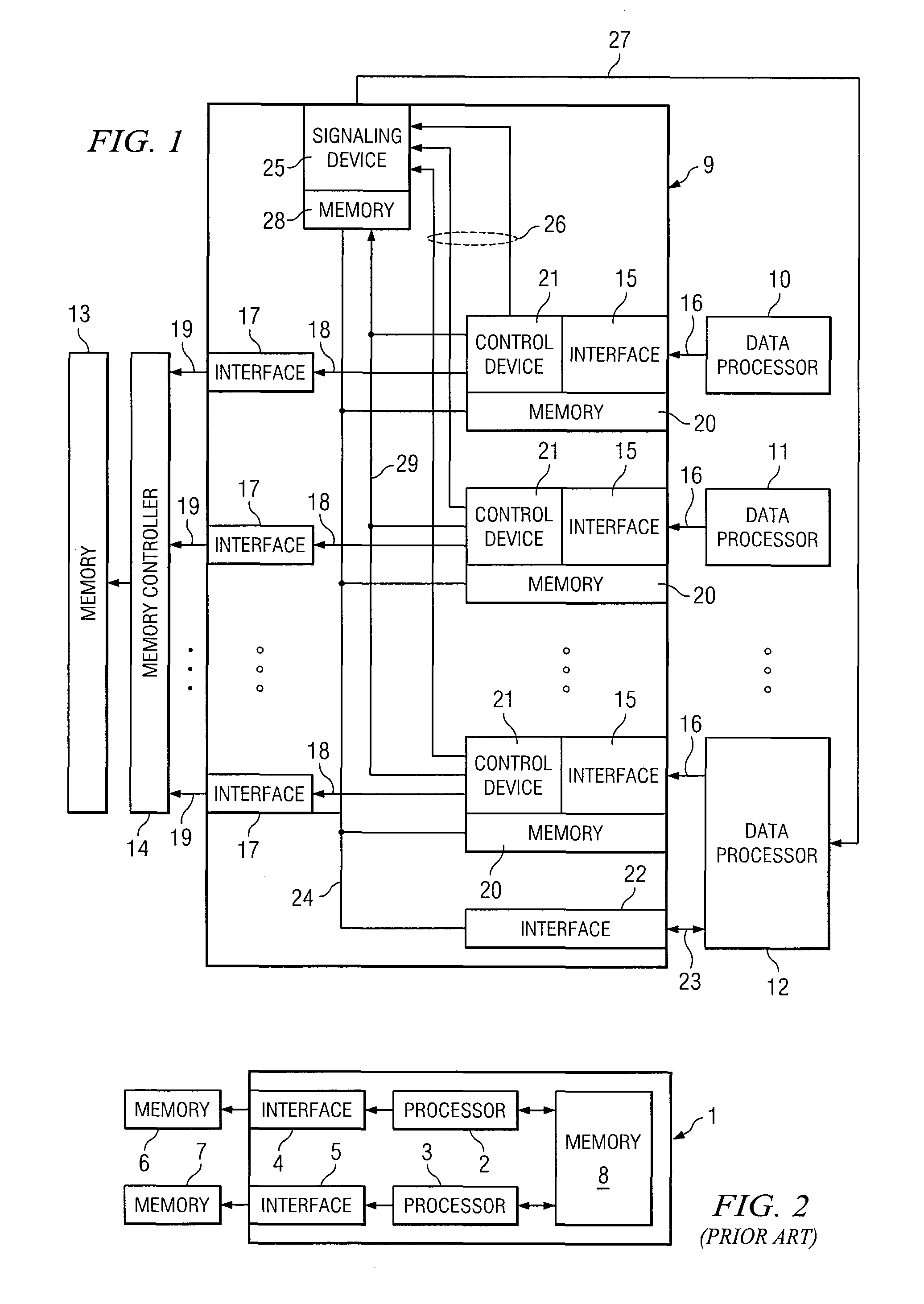

Apparatus and method for controlling the access operation by a plurality of data processing devices to a memory

ActiveUS8135920B2Improve integrityImprove securityEnergy efficient ICTUnauthorized memory use protectionEmbedded systemControl equipment

In an apparatus for controlling the access operation by a plurality of data processing devices to a memory, each data processing device (10, 11, 12) is assigned a respective address region which indicates the part of the addresses of the memory (13) which the respective data processing device can access. A control device (21) blocks an access operation by a data processing device to the memory (13) if the access operation address is not located in the address region which is assigned to the respective data processing device (10, 11, 12).

Owner:INFINEON TECH AG

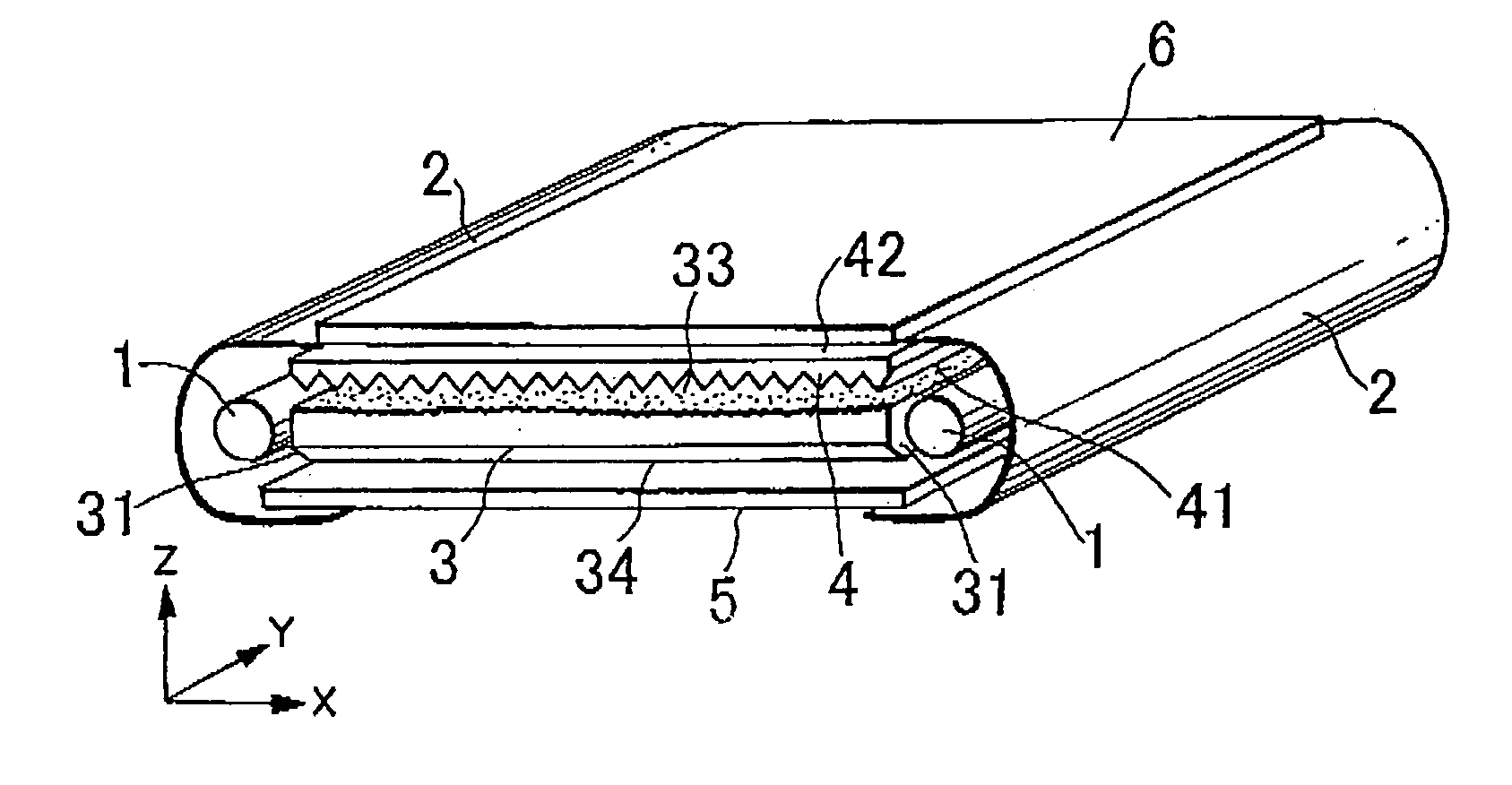

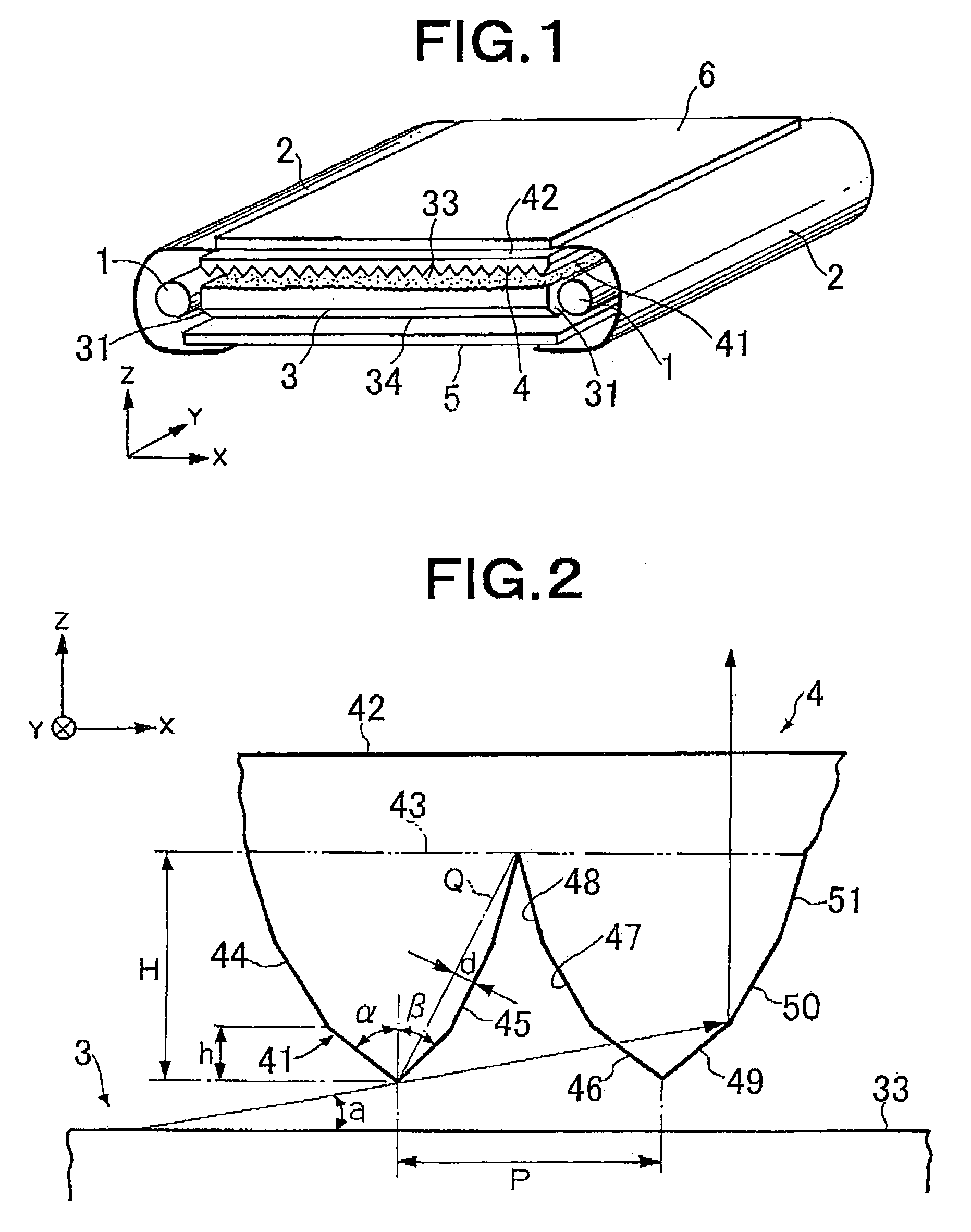

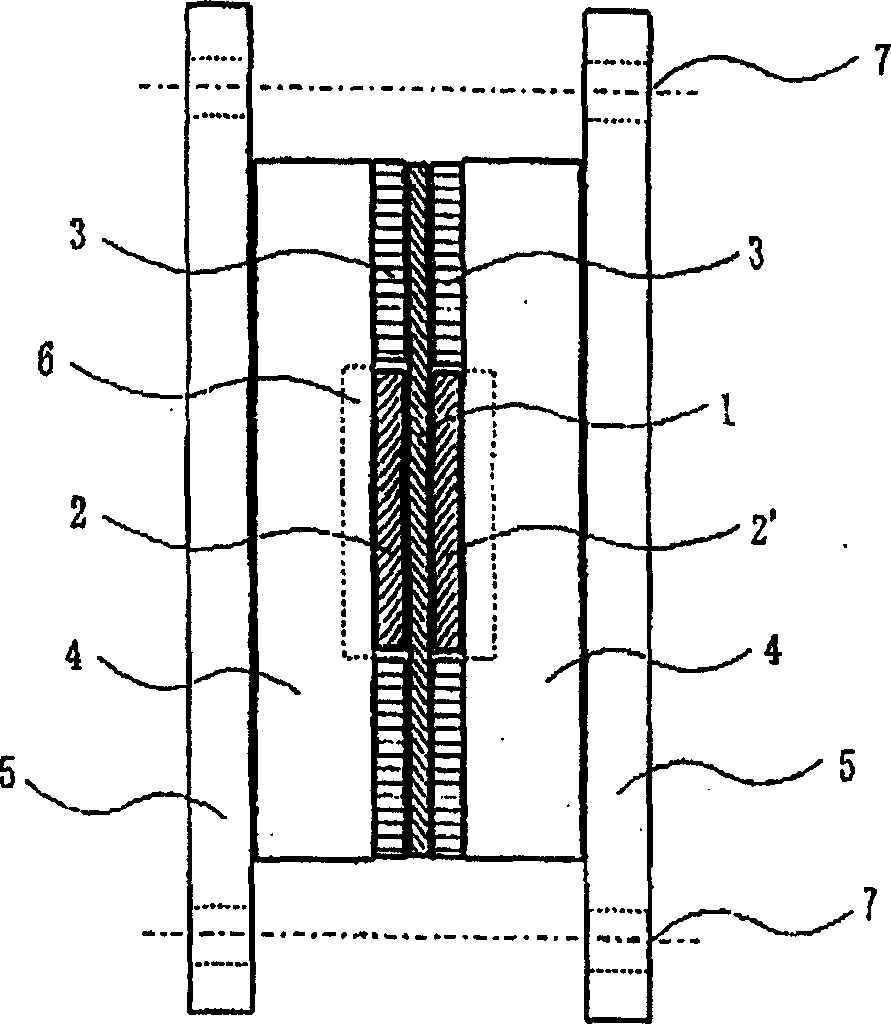

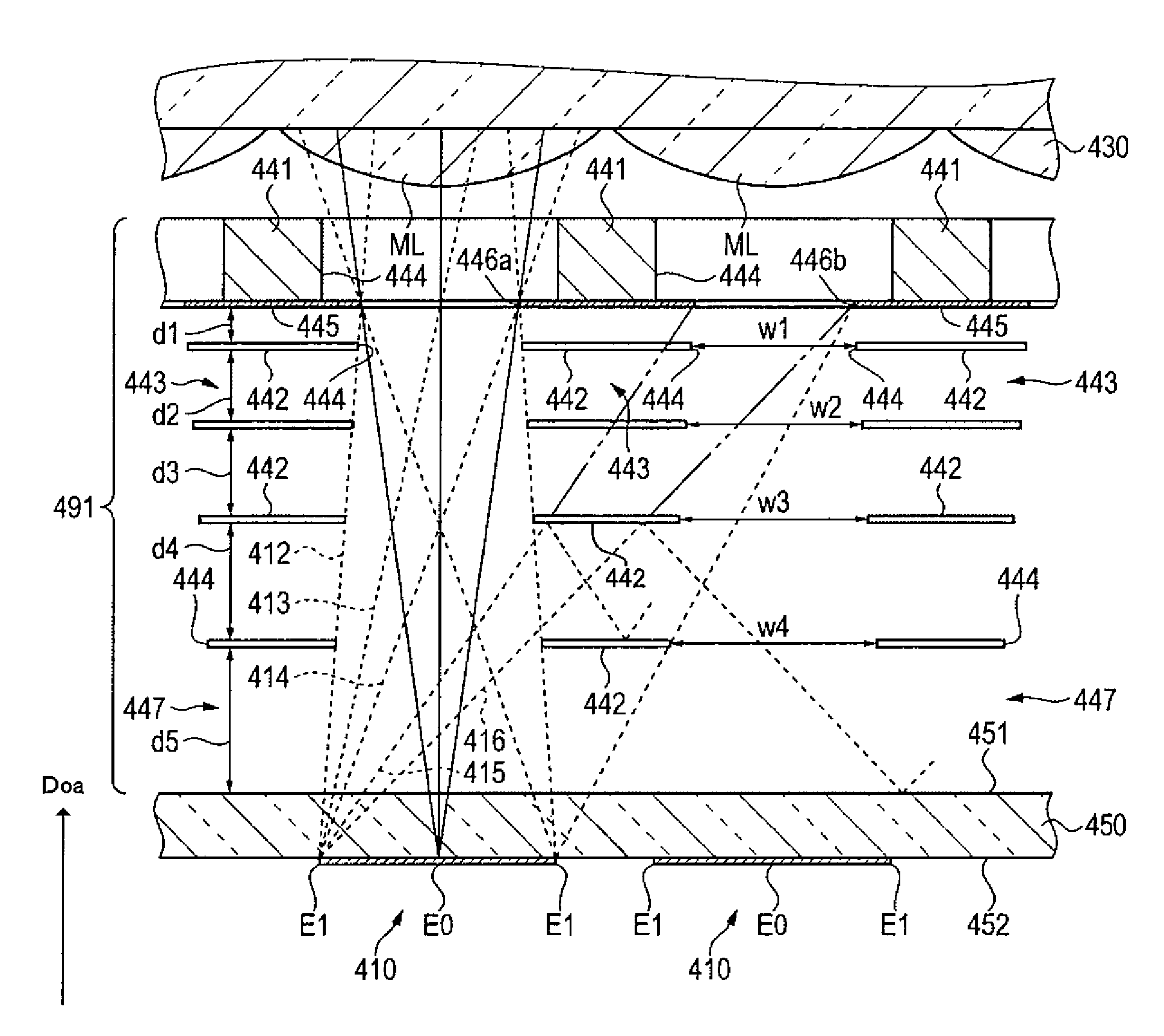

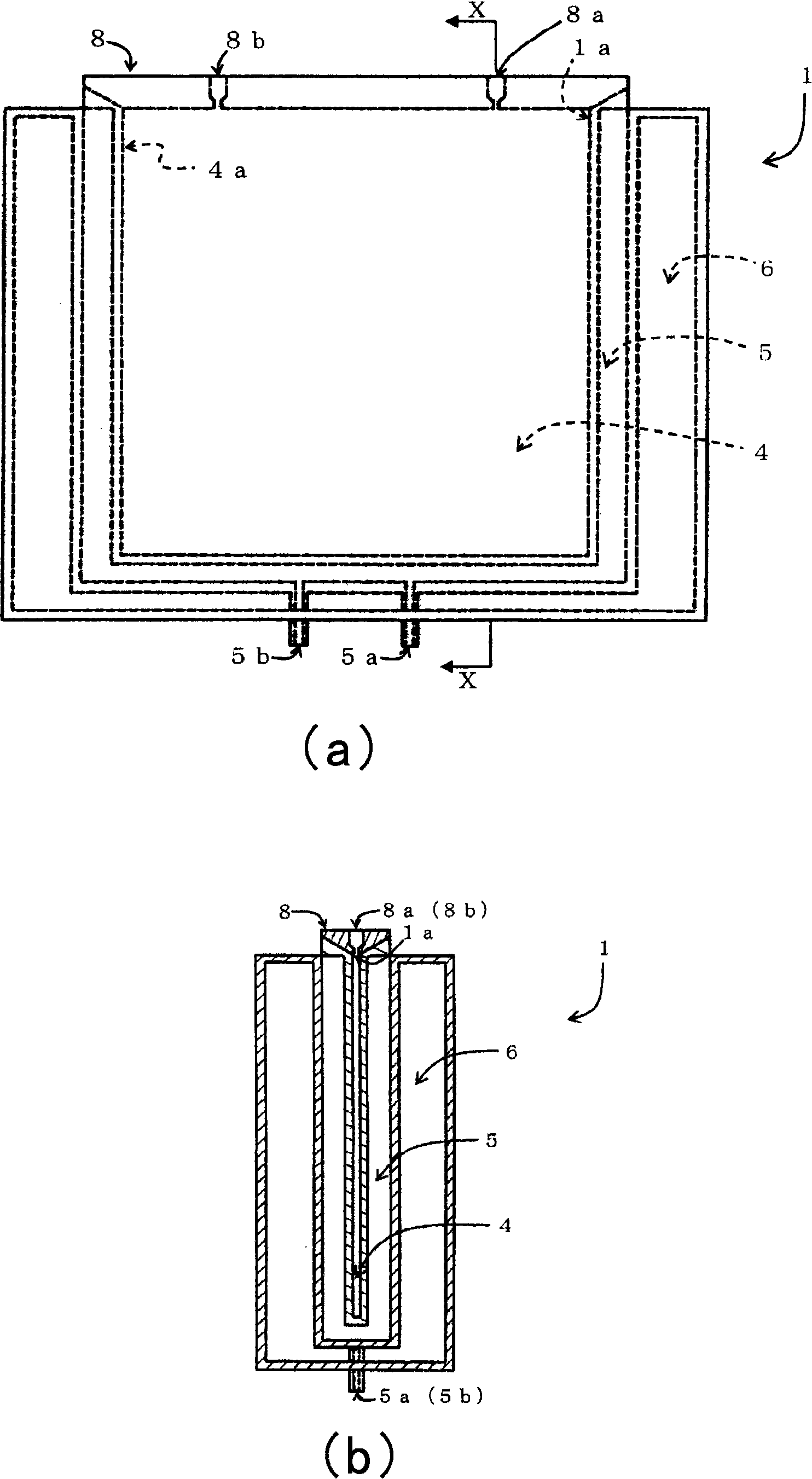

Light source device and light polarizing element

A light source device, comprising a light guide (3) having two light incident surfaces opposed to each other for receiving incident light radiated from a primary light source and a light outgoing surface (33) for emitting the incident light and a light deflection element (4) disposed adjacent to the light emitting surface side of the light guide, the light deflection element (4) further comprising a light receiving surface (41) for receiving incident light and a light emitting surface (42) positioned on the opposite side thereof and emitting the incident light, wherein a plurality of elongated prisms formed of two prism faces are disposed on the light receiving surface (41) generally parallel with each other, the prism surfaces are formed of at least two faces (46, 47, 48, 49, 50, 51) with different inclination angles, and the inclination angles are larger for the faces positioned nearer the light emitting surface (42).

Owner:LMS

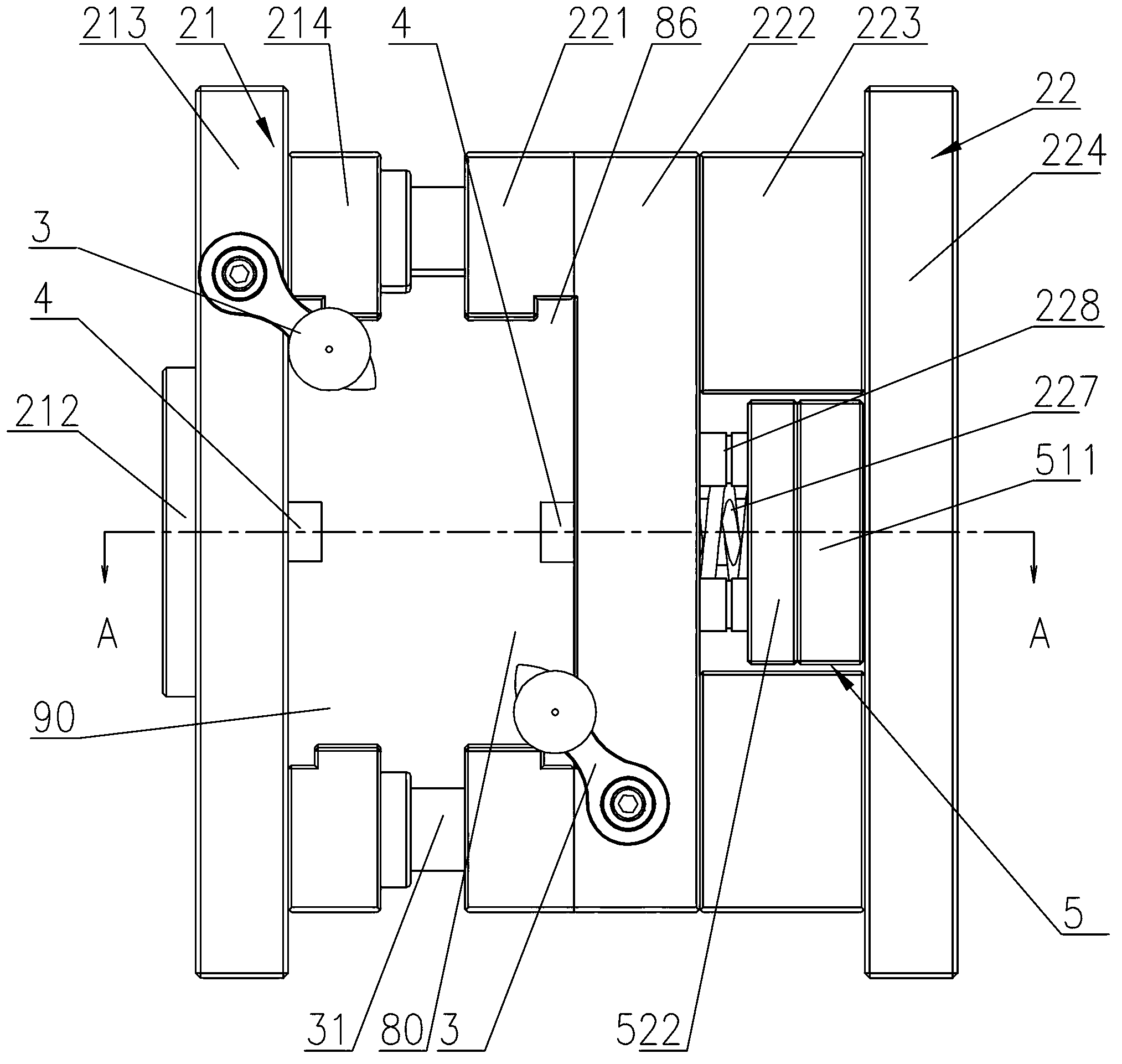

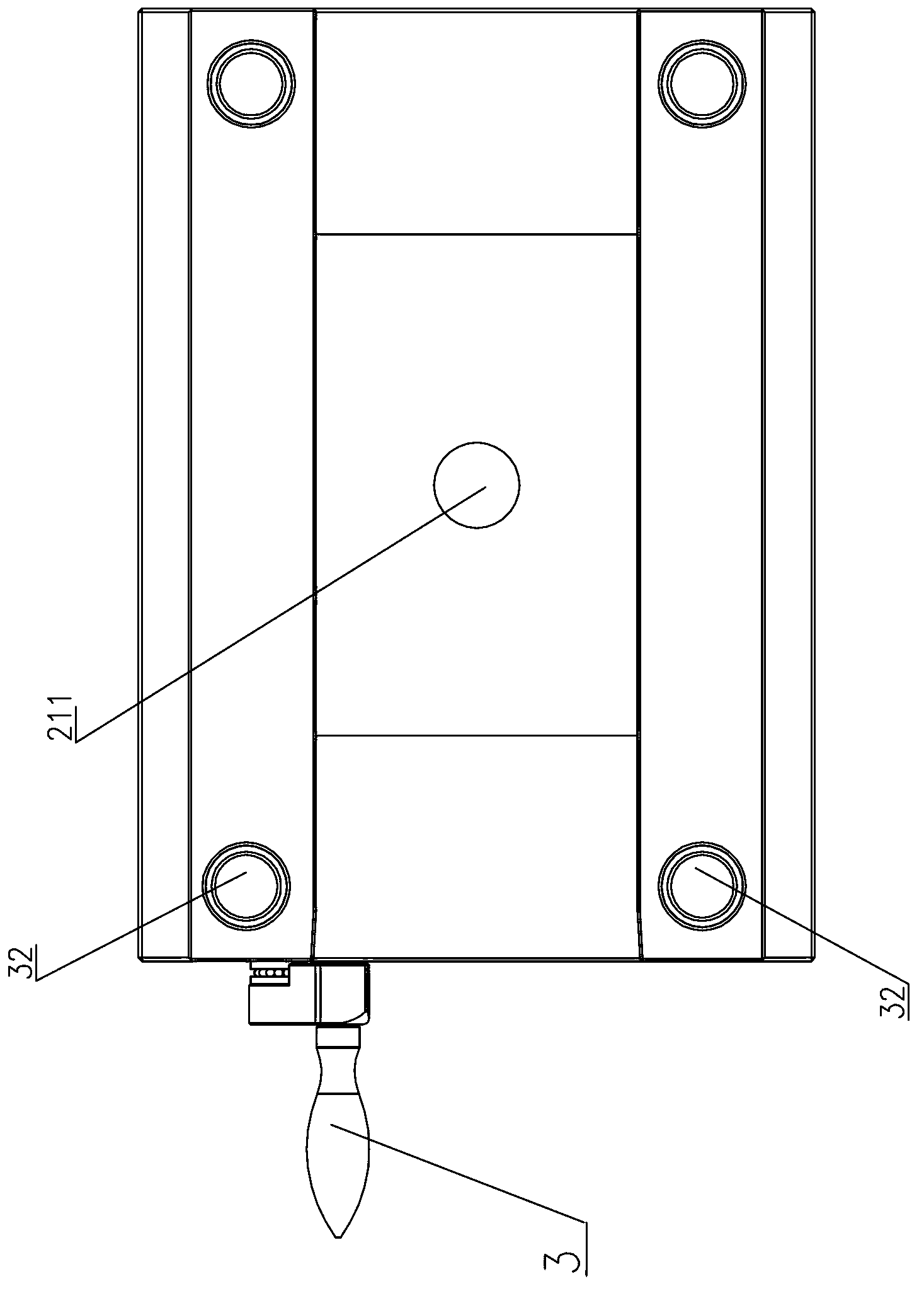

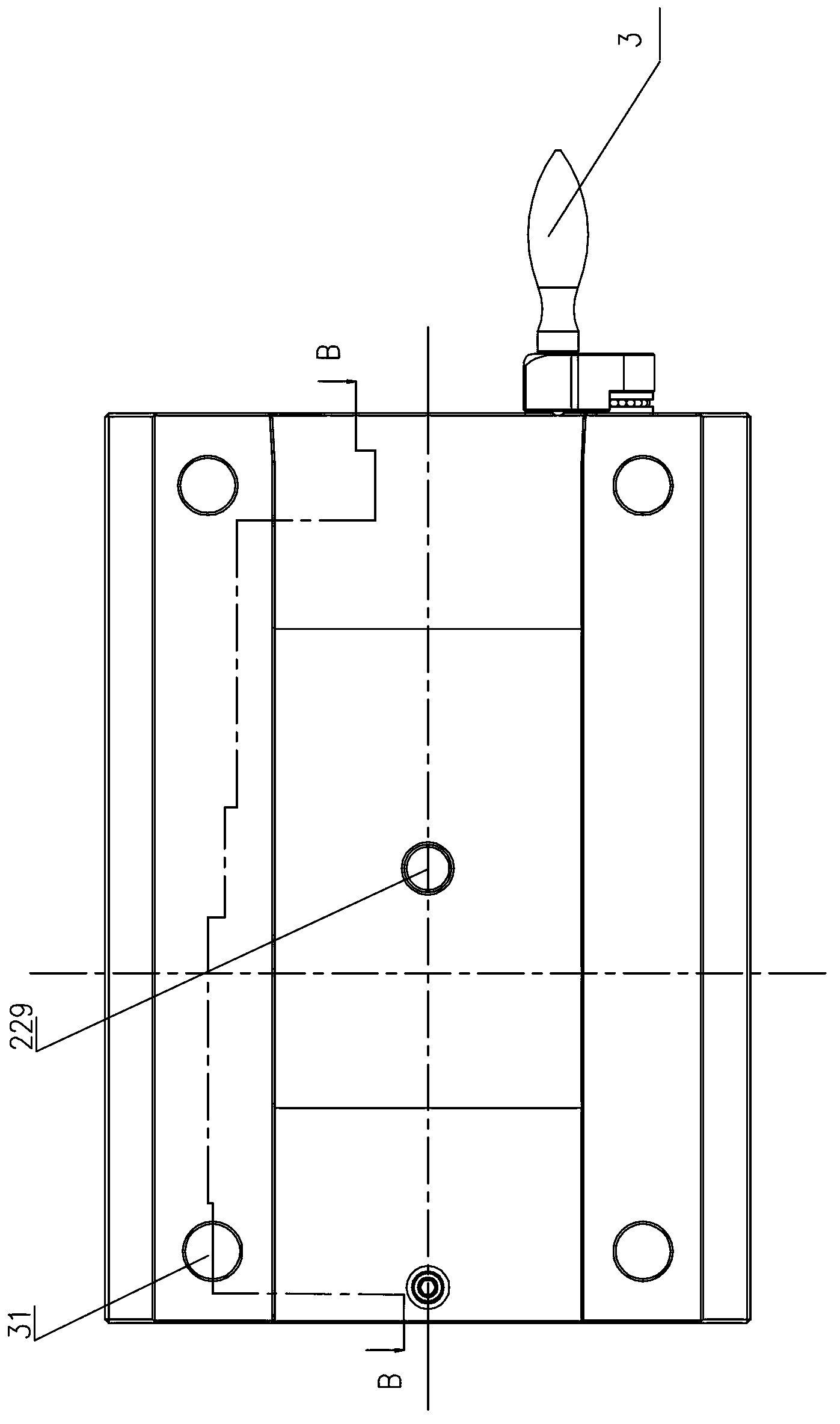

Injection mould with rapidly-replaced mould cores

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

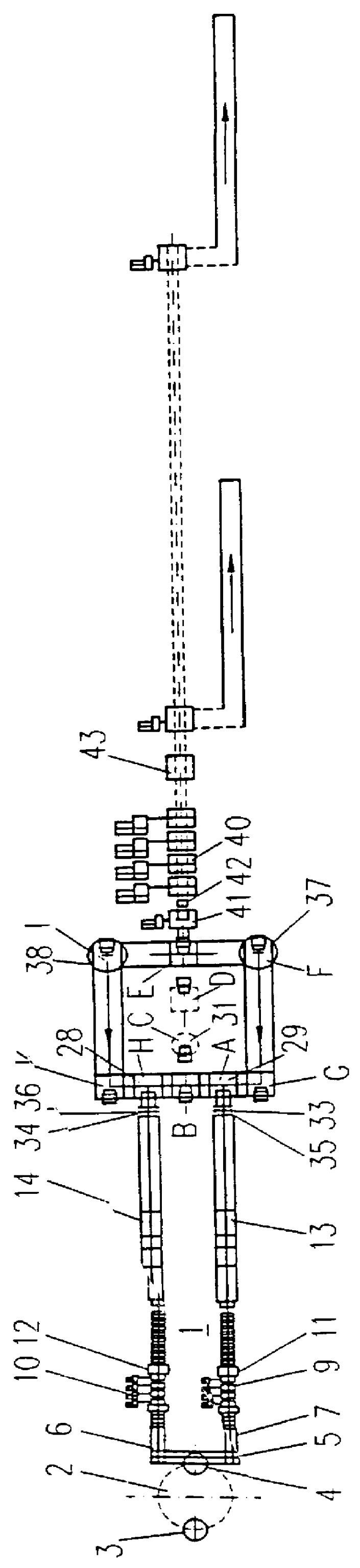

Method for the manufacture of a strip of formable steel

InactiveUS6053996AEasy constructionLower installed capacityFurnace typesMetal rolling arrangementsLiquid steelSteel belt

PCT No. PCT / EP96 / 02874 Sec. 371 Date Apr. 15, 1998 Sec. 102(e) Date Apr. 15, 1998 PCT Filed Jun. 28, 1996 PCT Pub. No. WO97 / 01402 PCT Pub. Date Jan. 16, 1997A method for the manufacture of a strip of formable steel comprises the steps of (i) forming liquid steel by continuous casting into a slab having a thickness of not more than 100 mm, (ii) rolling the slab in the austenitic region into an intermediate slab having a thickness in the range 5 to 20 mm, (iii) cooling the intermediate slab to below the Ar3 temperature, (iv) holding the intermediate slab in an enclosure for temperature homogenisation, (v) rolling the intermediate slab into strip, with at least one rolling pass applying a thickness reduction of more than 50%, at a temperature below Tt and above 200 DEG C., wherein Tt is the temperature at which 75% of the steel is converted into ferrite, and (vi) coiling said strip at a temperature above 500 DEG C. Advantages of simplicity of the method and the plant required for it are obtained.

Owner:HOOGOVENS STAAL BV

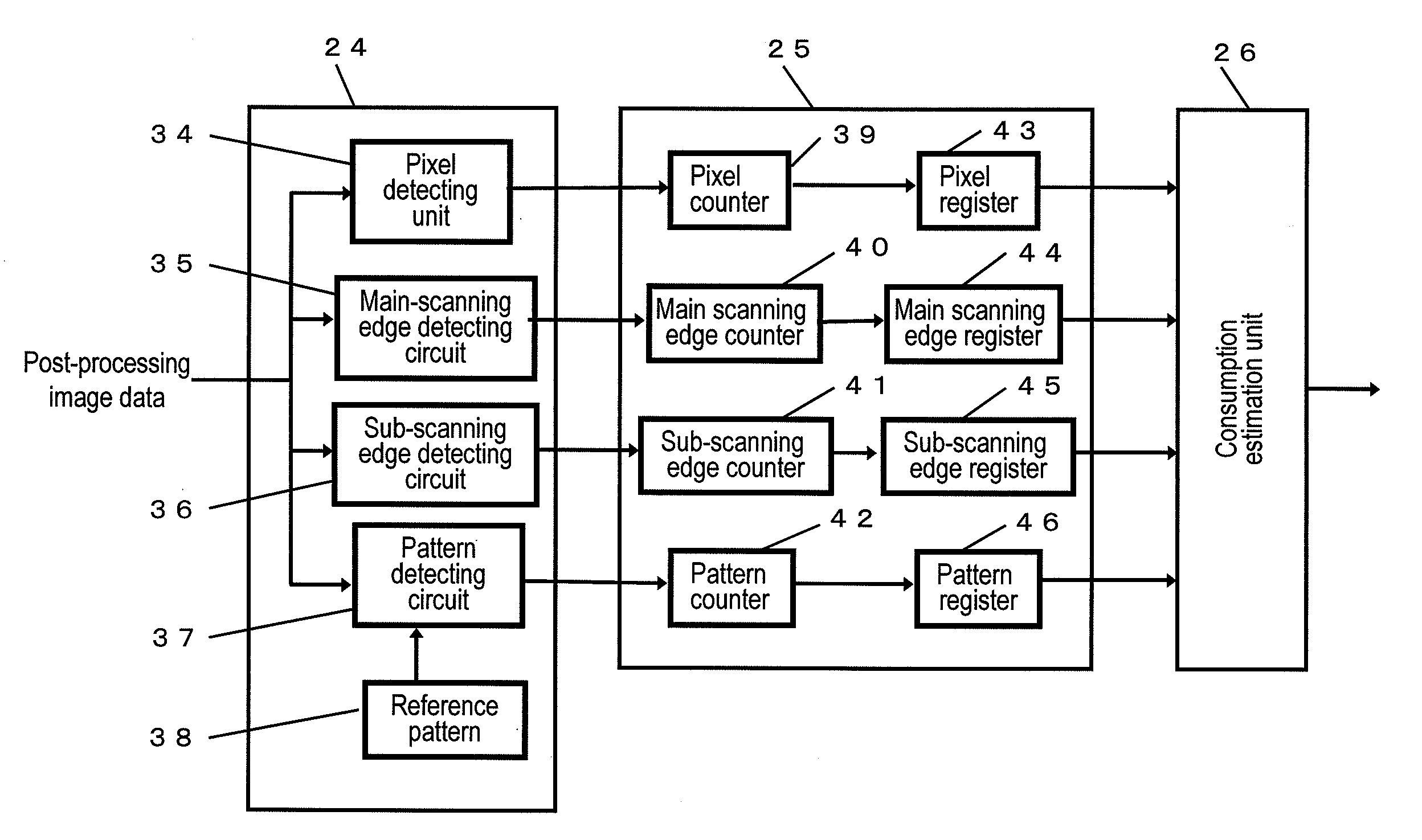

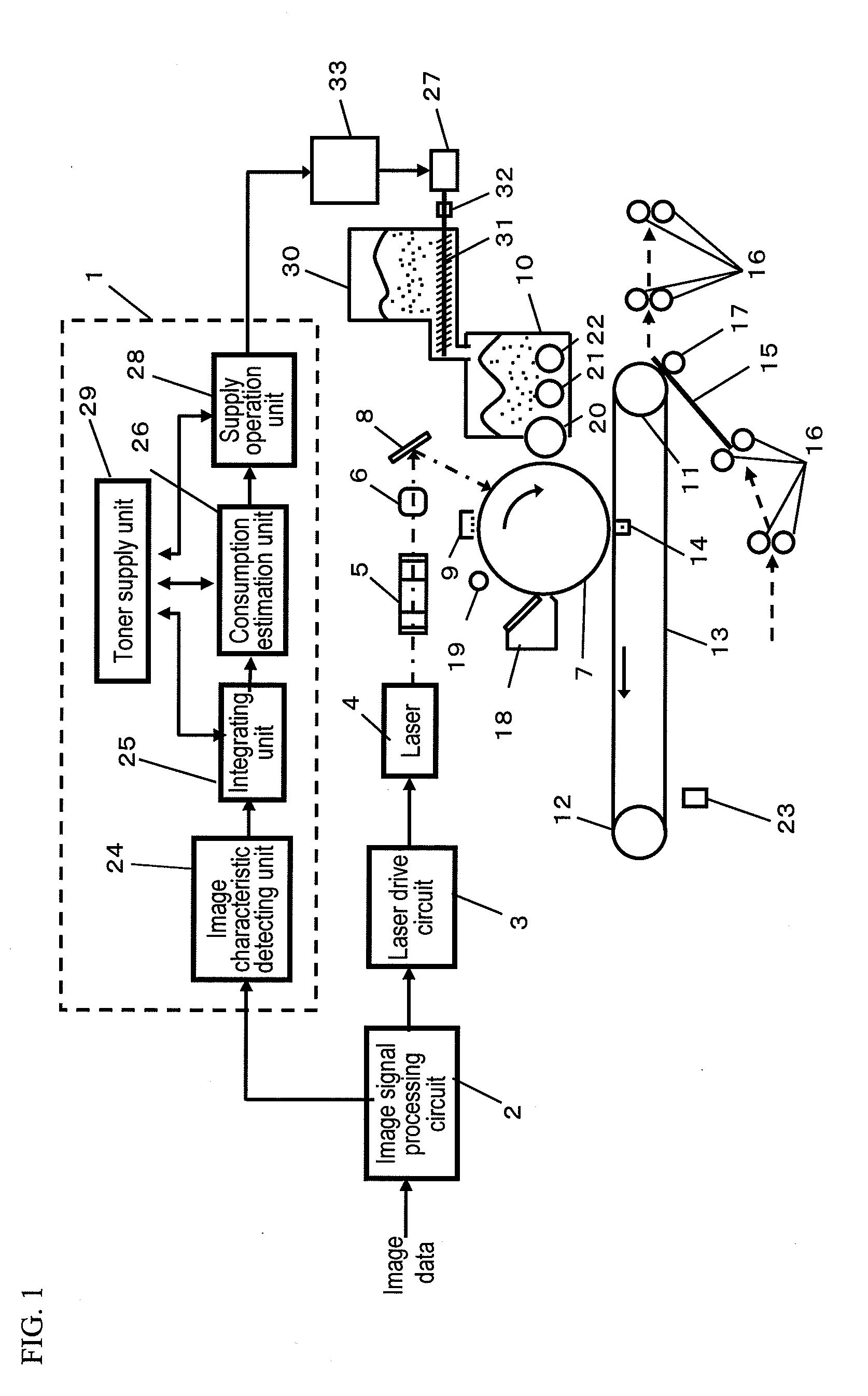

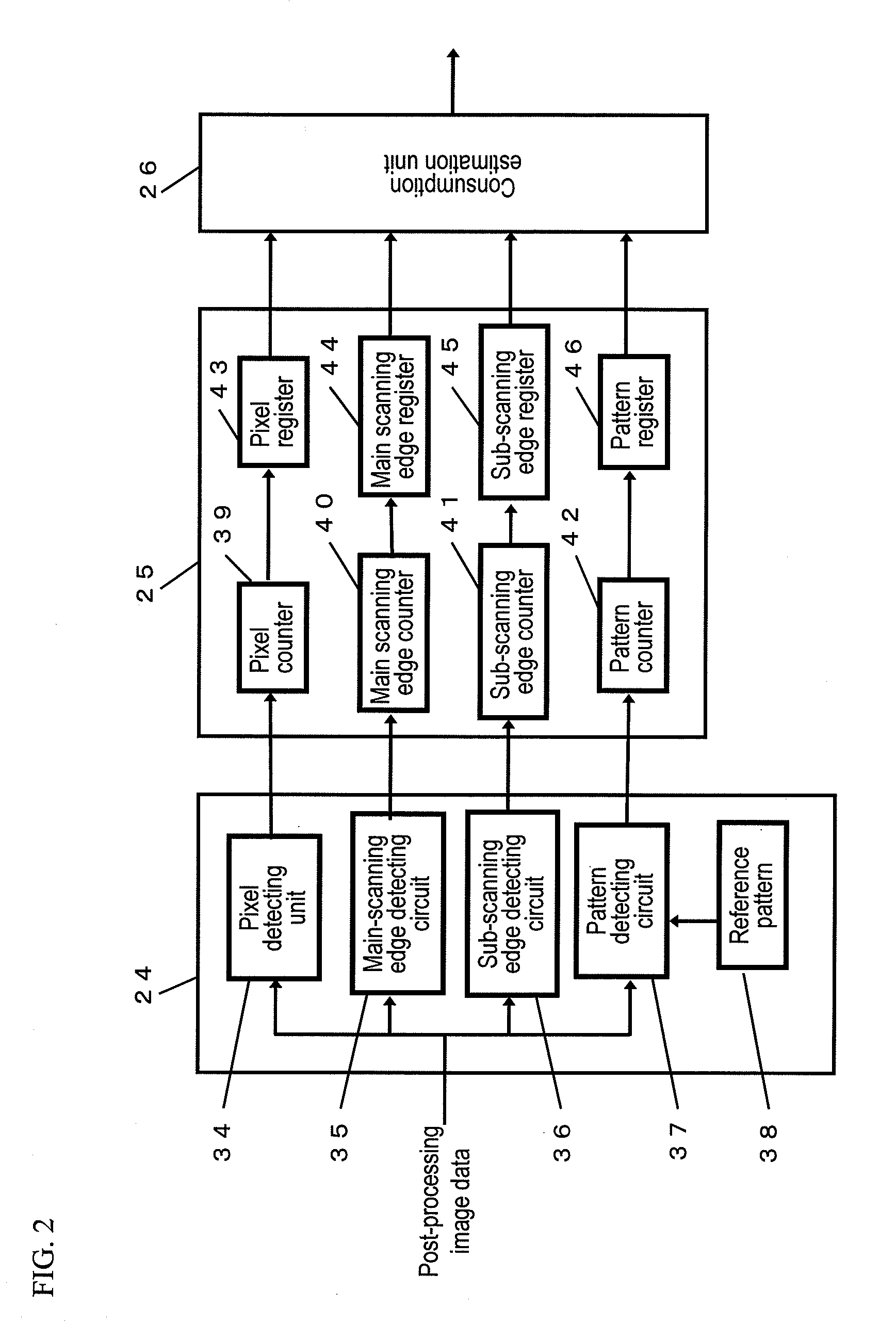

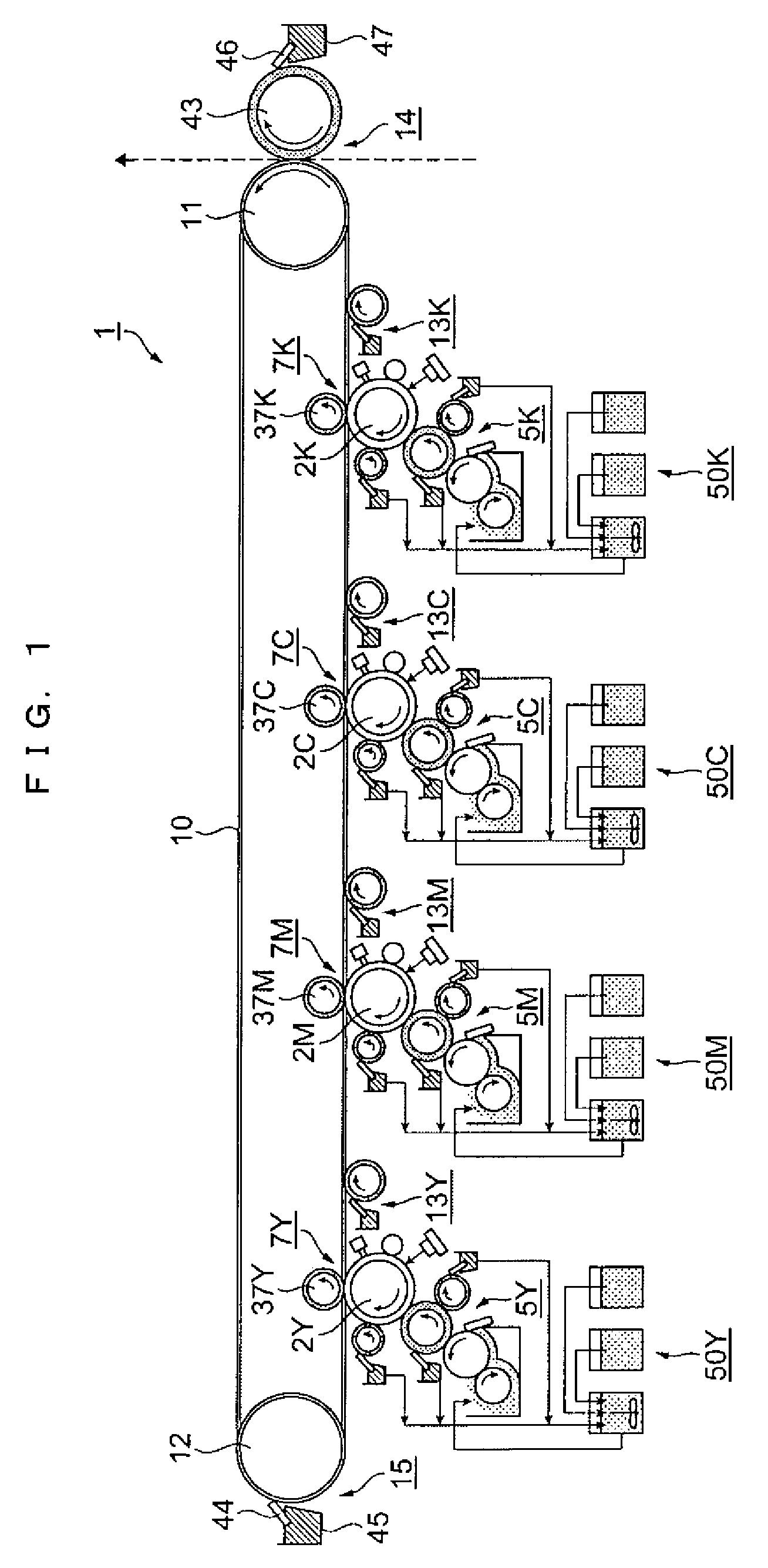

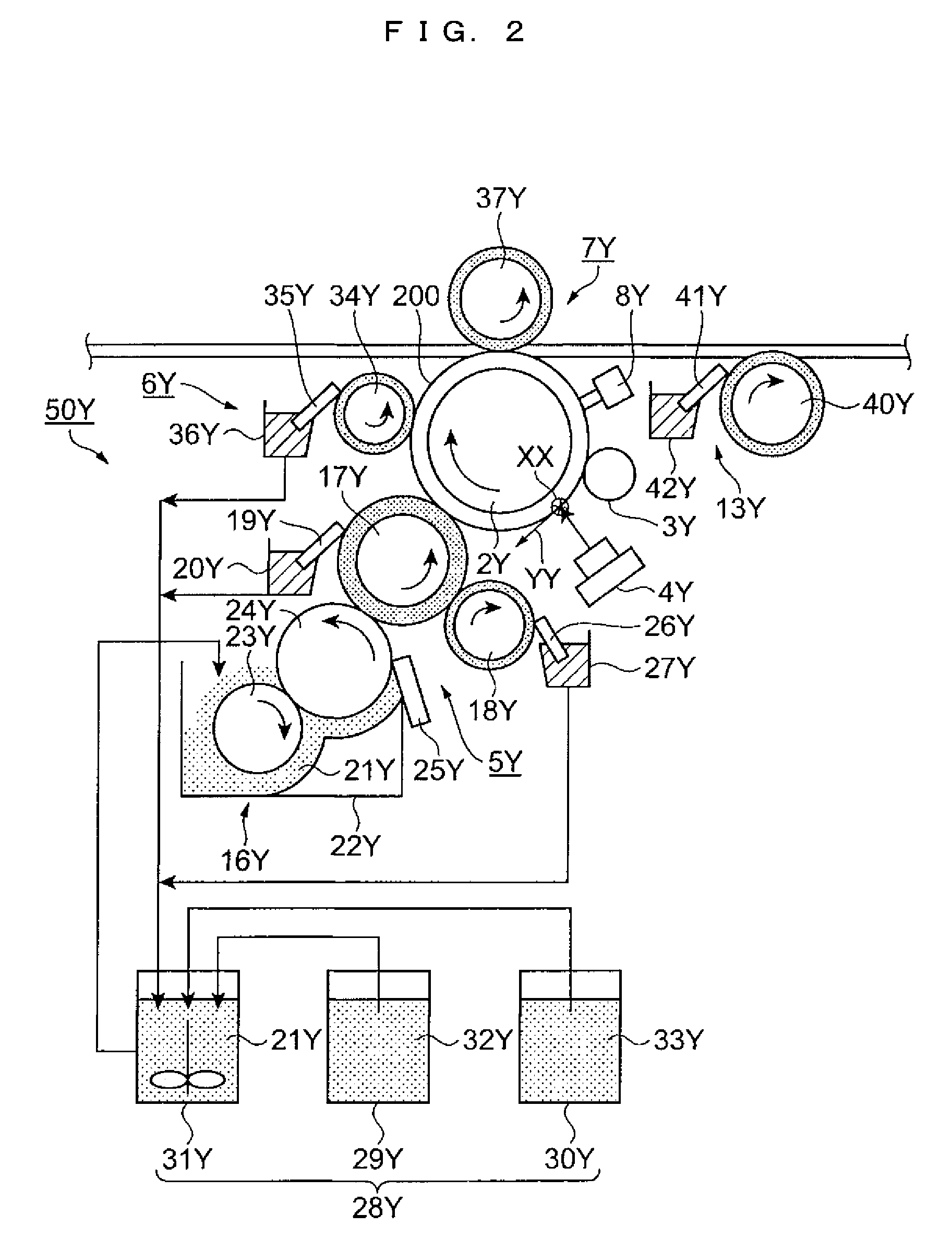

Developer supply device, developer supply control method, and developer supply control program

InactiveUS20090232524A1Reduce stepsToner concentration is smallElectrographic process apparatusImage formationElectrical and Electronics engineering

Owner:PANASONIC CORP

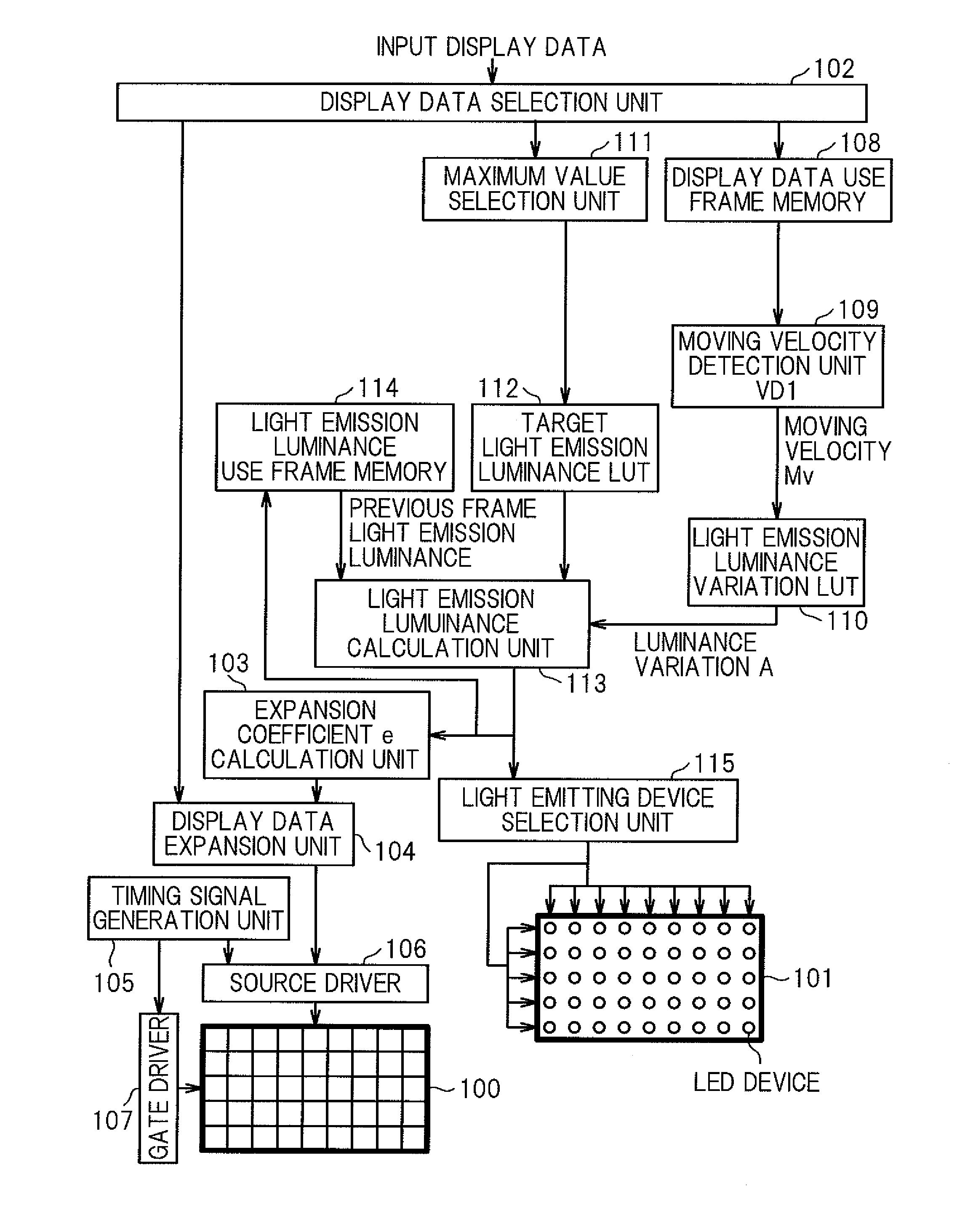

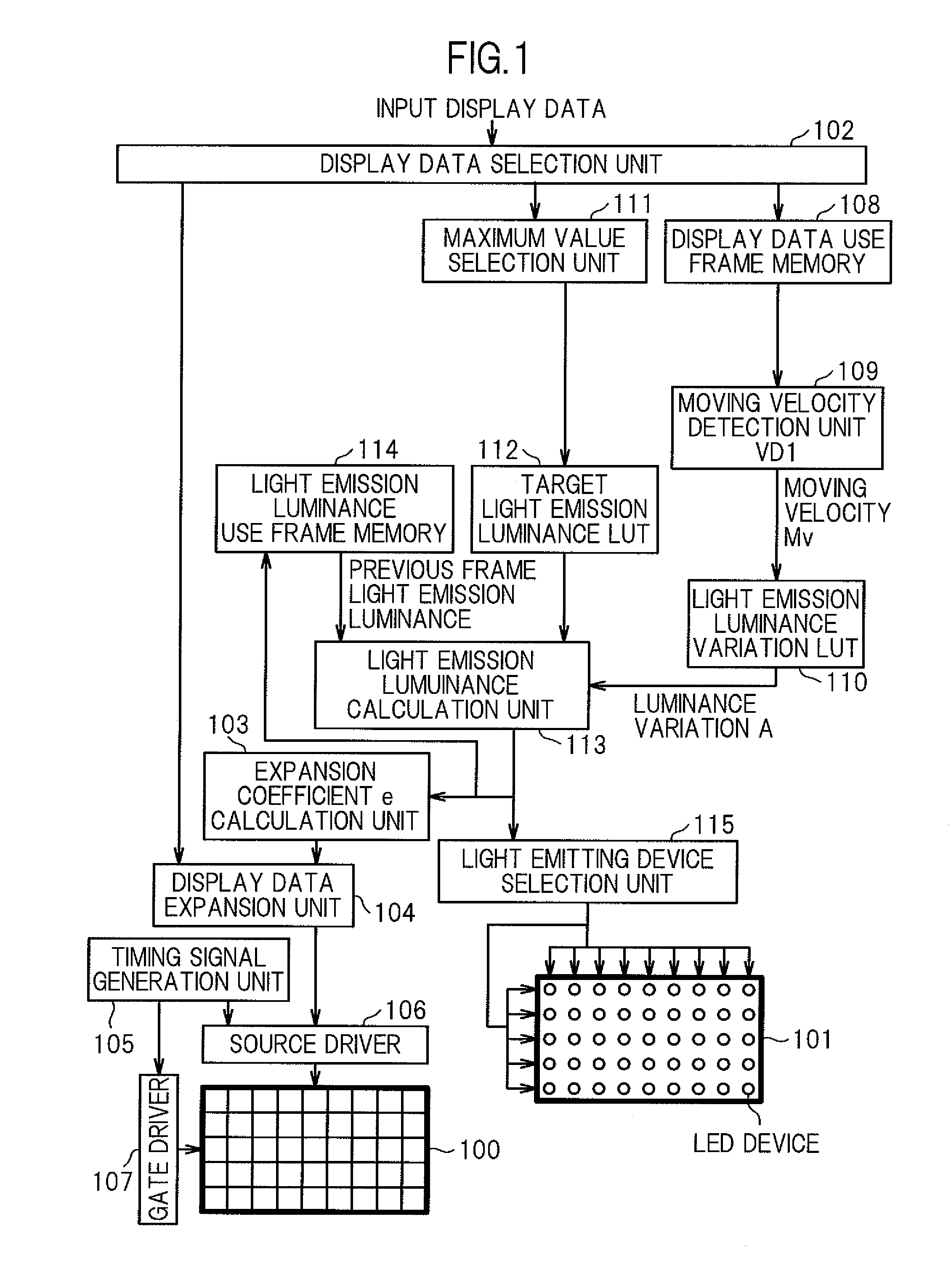

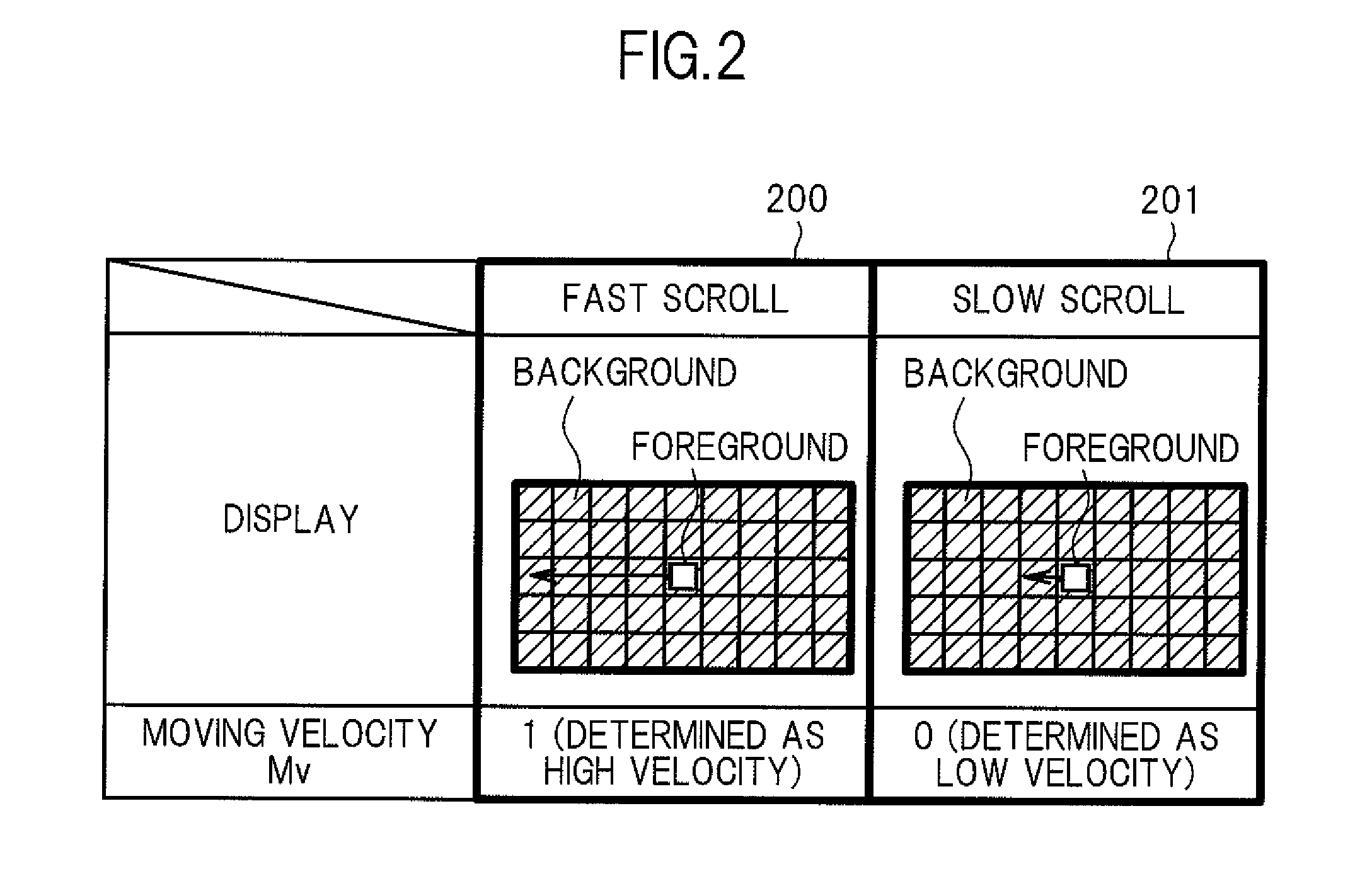

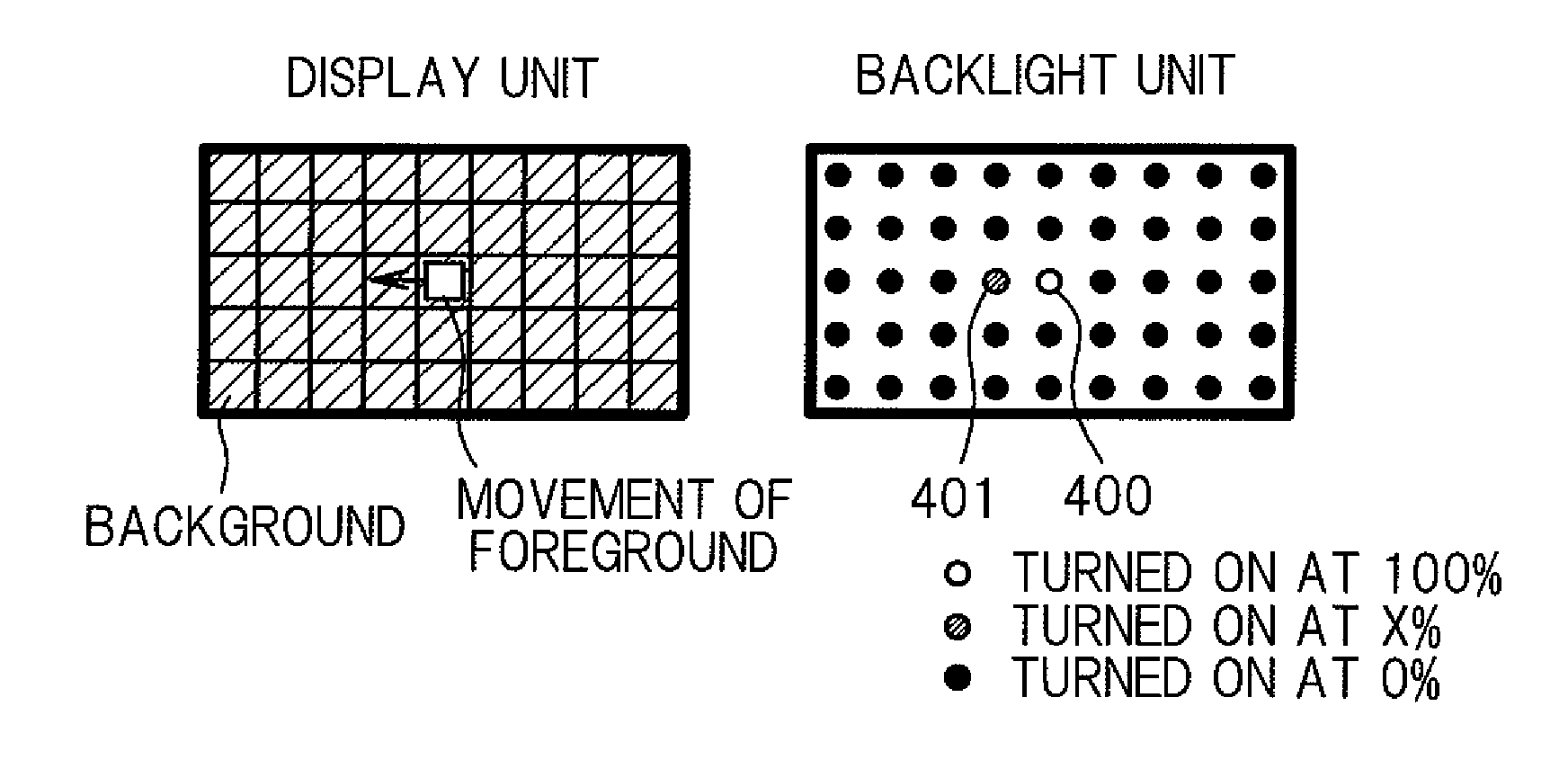

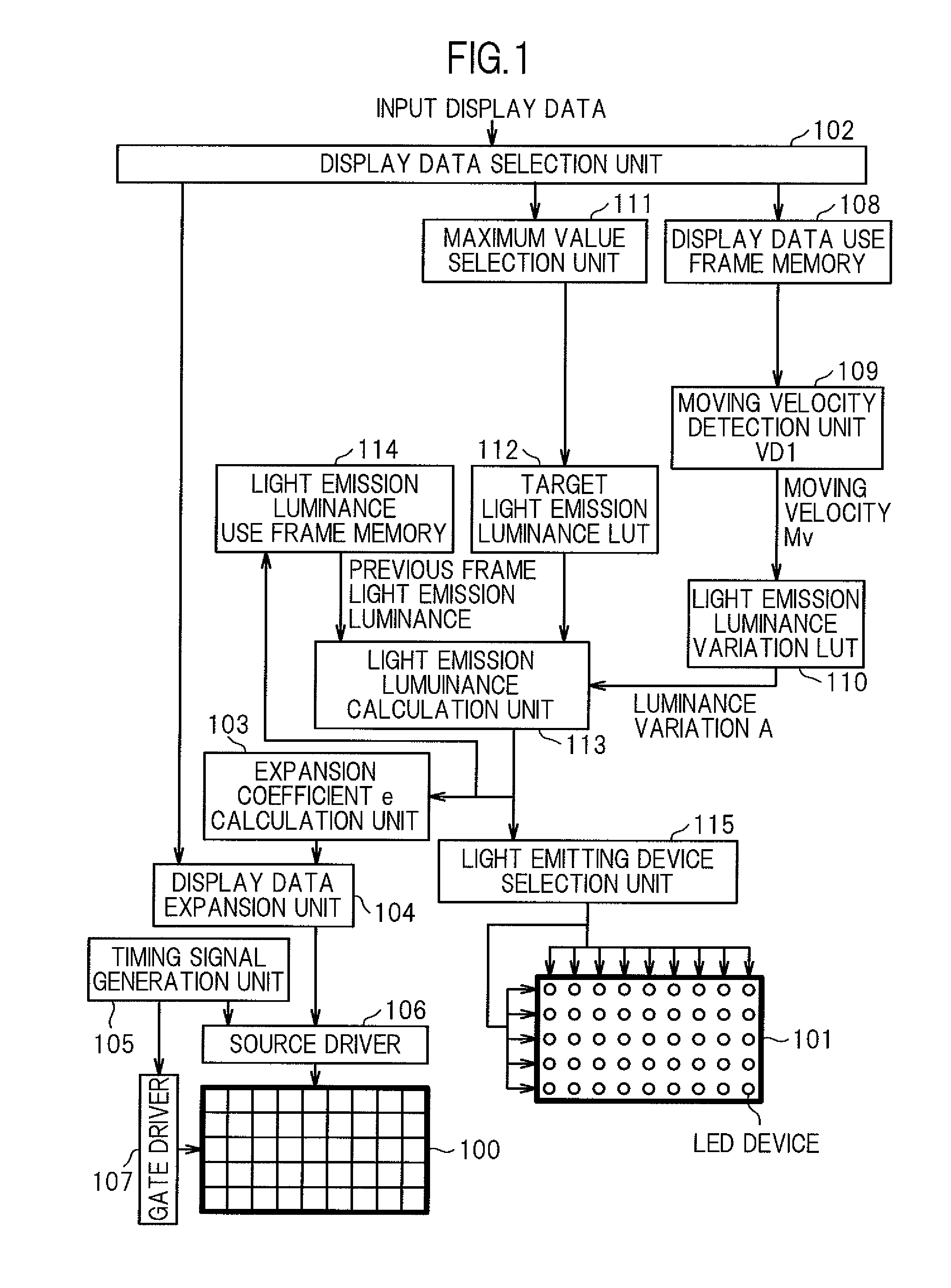

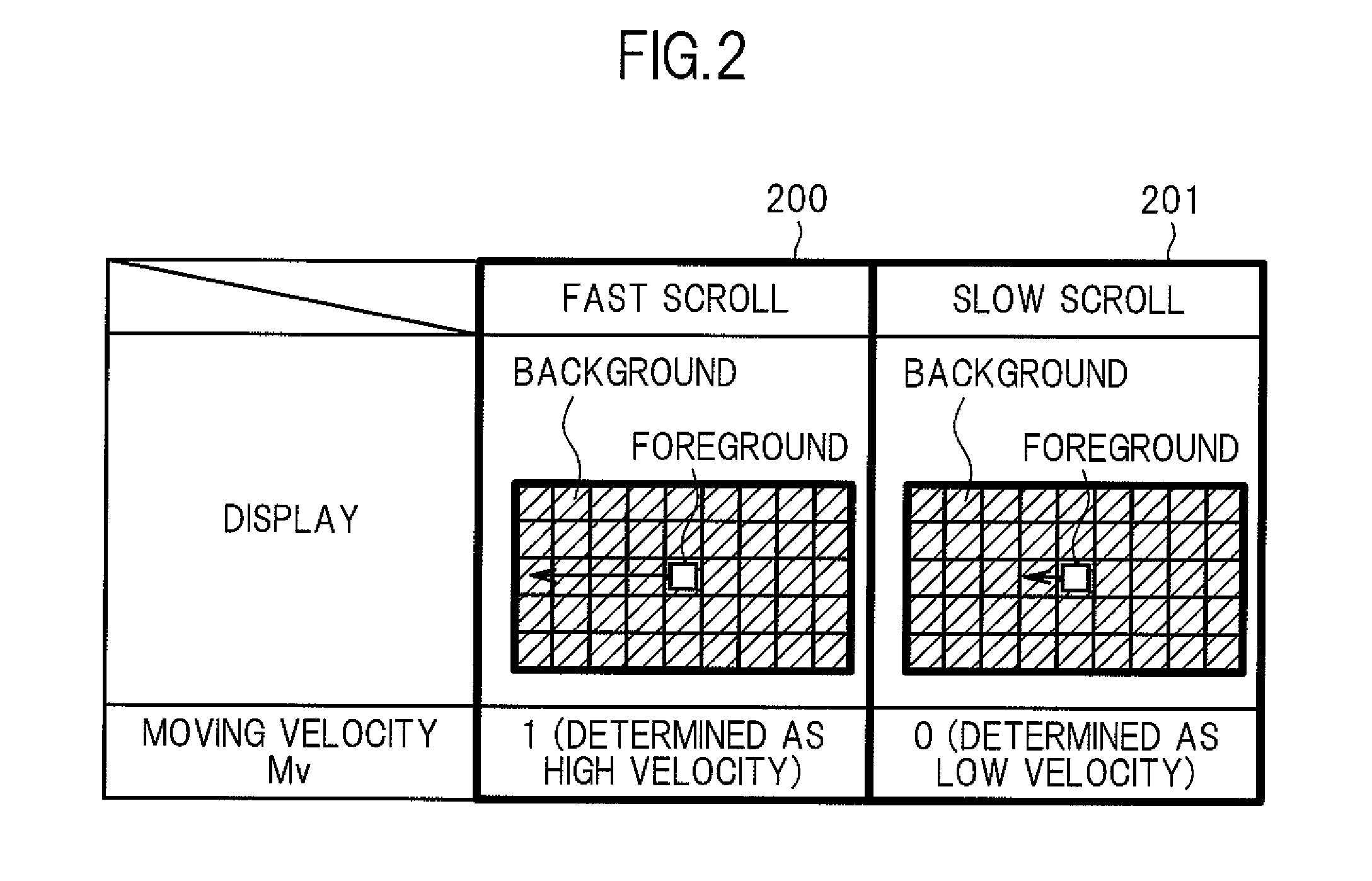

Display device

ActiveUS20100265405A1Quality improvementReduce flickerTelevision system detailsStatic indicating devicesDisplay deviceComputer vision

Provided is a display device capable of producing an image of excellent quality with reduced flicker and little reduction in luminance, the display device including: a backlight having light sources such as LED devices arranged two-dimensionally, each of which may be individually modulated in luminance; a moving velocity detection unit VD1 (109) for detecting a moving velocity of an object in a video (for example, moving velocity of a foreground); and a luminance variation control unit (113) for automatically controlling luminance variations of the LED devices for each frame, in accordance with the moving velocity.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Composite bamboo shoot fermenting agent and preparation method of fermented bamboo shoots

InactiveCN101999450AAppropriate proportionLow alcoholFruits/vegetable preservation using acidsFlavorAlcohol

The invention discloses a composite bamboo shoot fermenting agent and a preparation method of fermented bamboo shoots. The composite bamboo shoot fermenting agent contains monascus vinasse and liqueur koji. The preparation method of the fermented bamboo shoots comprises the following steps of: firstly, blanching bamboo shoots; and then, fermenting the bamboo shoots under the action of the composite bamboo shoot fermenting agent. Under the action of the composite bamboo shoot fermenting agent, aromatic substances, pigments, and the like in the vinasse are infiltrated in the bamboo shoot tissues. The prepared vinasse-processed bamboo shoots have the characteristics of unique fragrance and flavor, mellow and pleasant taste, elegant flavor, attractive color and rich nutrition. The preparation method can effectively prevent fresh bamboo shoots from aging, lessen the loss of nutrient contents, preserve the nutrient contents of the bamboo shoots and ensure the quality and the grade of the bamboo shoots. The fermented bamboo shoots prepared by using the method disclosed by the invention have appropriate proportions of liquor, sugar and acid, and have the advantages of low alcohol and sugar contents, stable resistance to acid and alkali, strong heat resistance and light resistance, stable resistance to oxidoreduction and favorable practical values and application prospects.

Owner:健盛食品股份有限公司

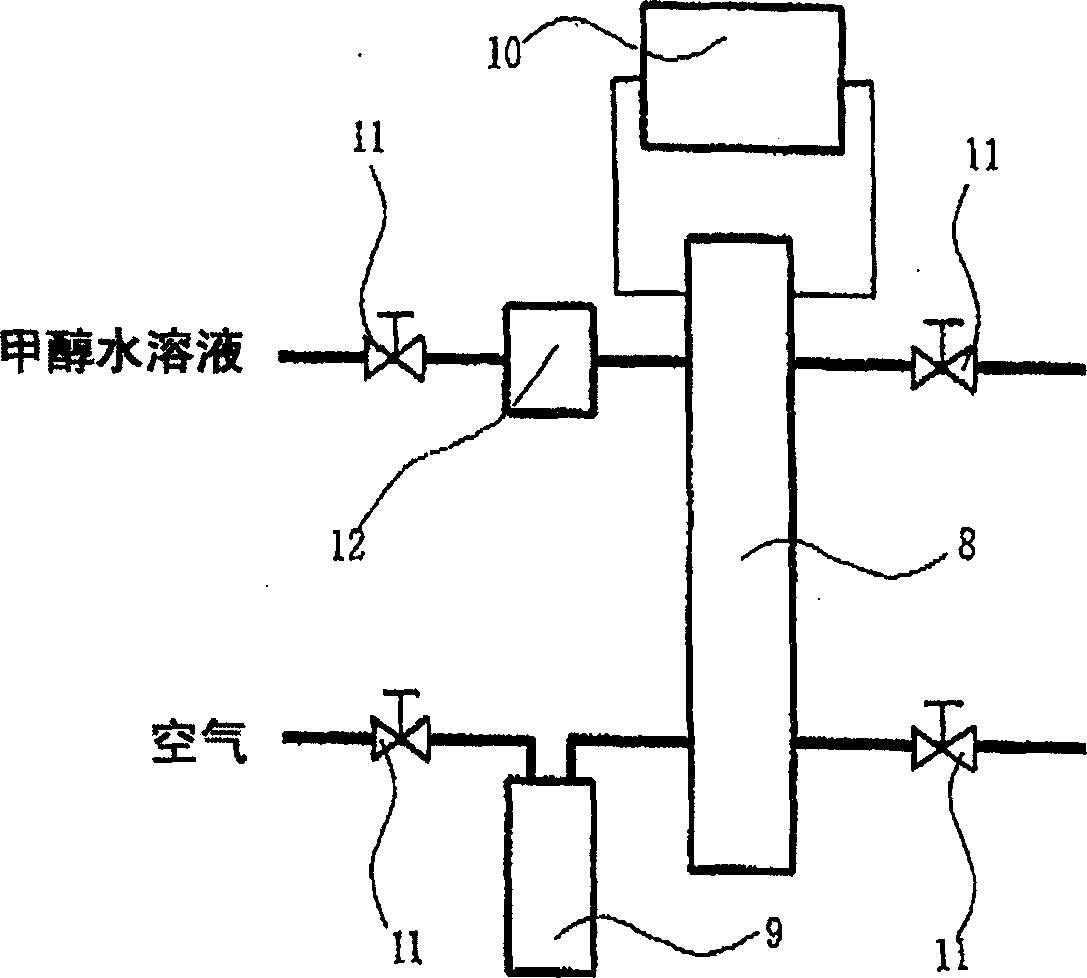

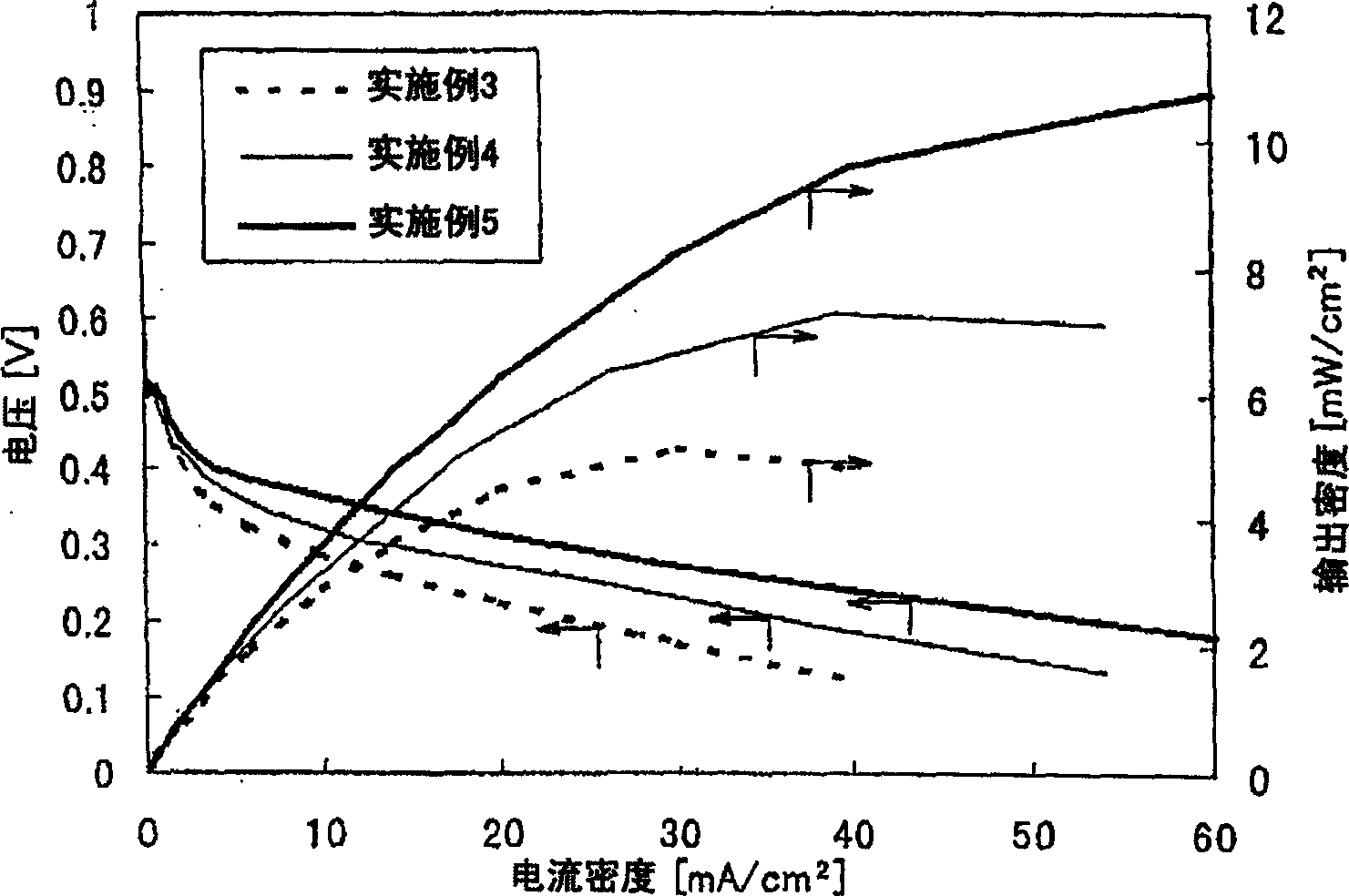

Crosslinkable aromatic resin having protonic acid group, and ion conductive polymer membrane, binder and fuel cell using the resin

InactiveCN1630676ALow denaturationImprove heat resistanceCell electrodesFinal product manufactureConductive polymerPolypyrrole

Owner:MITSUI CHEM INC

Coating agent for refreshing bamboo shoots and method for refreshing bamboo shoots with shells

InactiveCN101731325APrevent browningPrevent dehydrationFruits/vegetable preservation by coatingFiberBamboo shoot

The invention discloses a coating agent for refreshing bamboo shoots and a method for refreshing the bamboo shoots with shells. The coating agent for refreshing the bamboo shoots comprises chitosan, konjac glucomannan and iso-vitamin C. The method for refreshing the bamboo shoots with the shells comprises the steps of coating, cooling and refrigerating the bamboo shoots with the shells sequentially. The preservative bamboo shoots prepared by the method has the advantages of high whiteness and moisture content, little increment of crude fiber content, little reduction in the content of total sugar and vitamin C and little loss of nutrient substances in the bamboo shoots. The method effectively retards the ageing speed of the bamboo shoots and obviously prevents brown stain, dehydration, ageing and mildew.

Owner:FUJIAN XINRIXIAN GRP

Developing roller, developing device, process cartridge, and image forming apparatus

InactiveUS20140321888A1Avoid shootingSmall extent of reductionElectrographic process apparatusVinyl etherSurface layer

A developing roller, including: a shaft containing a metal; an elastic layer on a circumference of the shaft; and a surface layer on a circumferential surface of the elastic layer, wherein the surface layer contains: a polyurethane which is a reaction product between a fluoroethylene vinyl ether copolymer and an isocyanurate form of an isocyanate; and particles having an average primary particle diameter of 5 nm to 30 nm, and wherein the polyurethane has a peak intensity ratio of a NCO group to a hydroxyl group of 5.6 to 8.8 in an infrared absorption spectrum obtained by an attenuated total reflection method.

Owner:RICOH KK

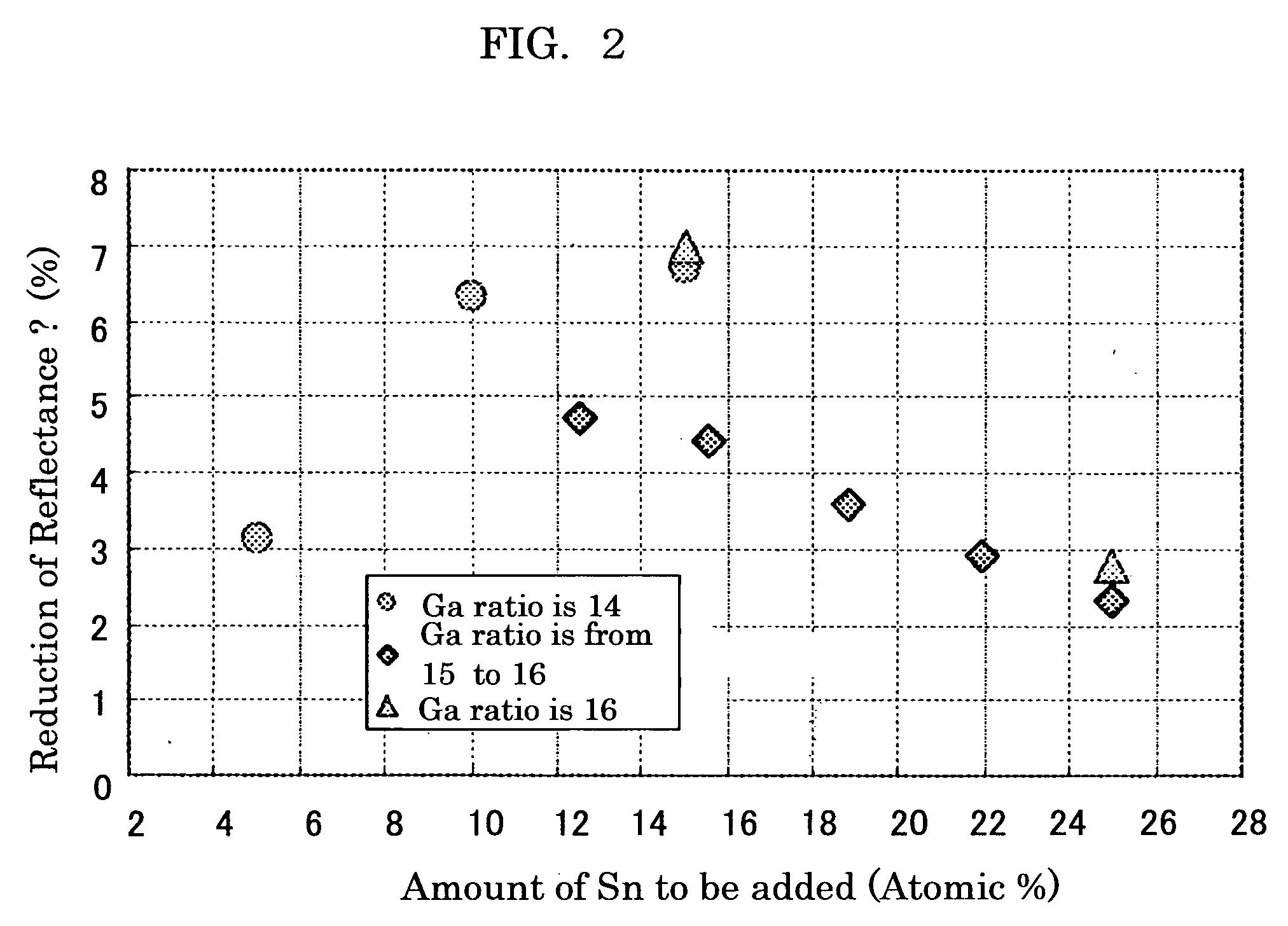

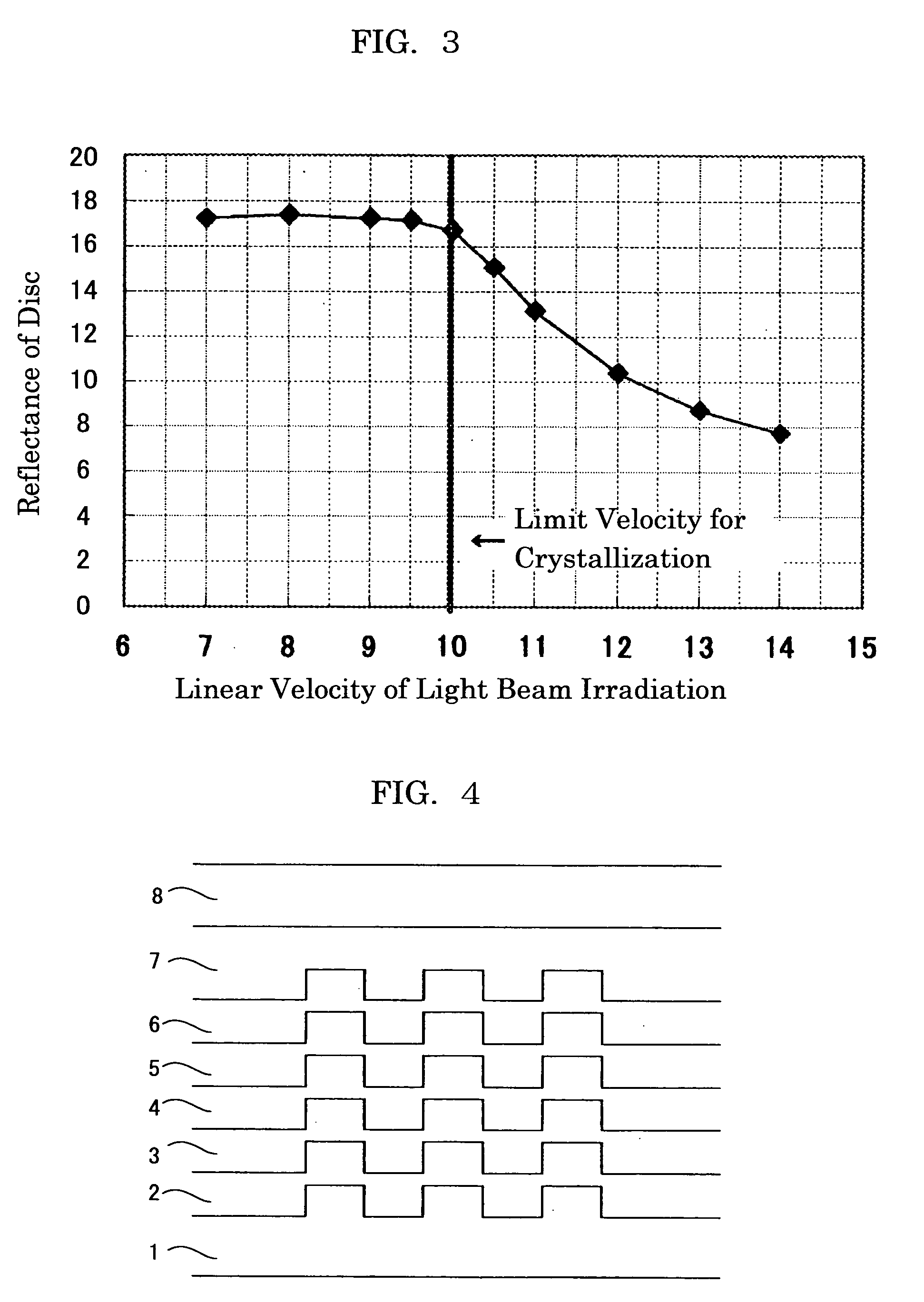

Optical recording medium

InactiveUS20060246270A1Small reductionRecord information storageRecording layersAmorphous phaseRecording layer

An optical recording medium including: a substrate having translucency; a first protective layer thereon; a recording layer composed of a phase-change material; a second protective layer; and a reflective layer, wherein laser beam irradiation causes phase-change of the recording layer between a crystalline phase and an amorphous phase thereby at least one of to rewrite and to record information, wherein the phase-change material comprises Ga, Sb and Sn, Ga content, Sb content, and Sn content satisfy the following formula, and the total content of Ga, Sb and Sn is at least 80 atomic % of the entire phase-change material: GaαSbβSnγ (where, α+β+γ=100 atomic %), where 20≦−2.75α+0.708β+1.18γ−7.56≦43, and α / (α+β)≦0.12.

Owner:RICOH KK

Transparent crystalline electrically-conductive thin film, method of production thereof, transparent electrically-conductive film, and touch panel

ActiveUS20090117405A1Improve crystallization speedLower performance requirementsConductive materialVacuum evaporation coatingHigh resistanceIndium

A transparent crystalline electrically-conductive thin film of the present invention comprises an indium tin oxide as a main component, wherein the indium tin oxide contains 9% by weight or less of tin oxide based on the total amount of indium oxide and tin oxide, wherein the transparent crystalline electrically-conductive thin film contains 0.45 atomic % or less of nitrogen. The transparent crystalline electrically-conductive thin film of the present invention has a high resistance value and good reliability in a high-temperature, high-humidity environment.

Owner:NITTO DENKO CORP

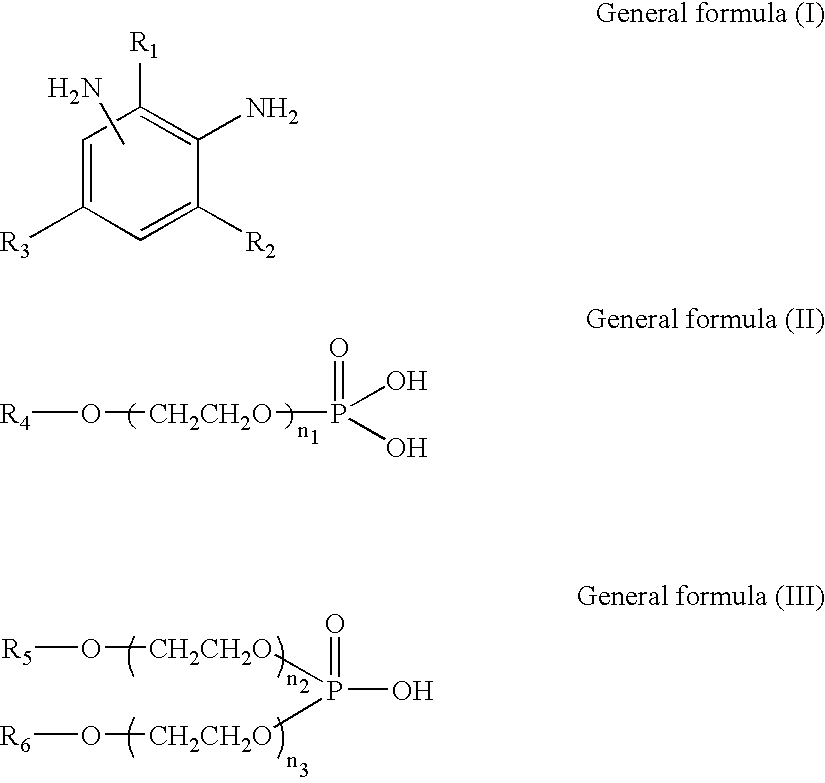

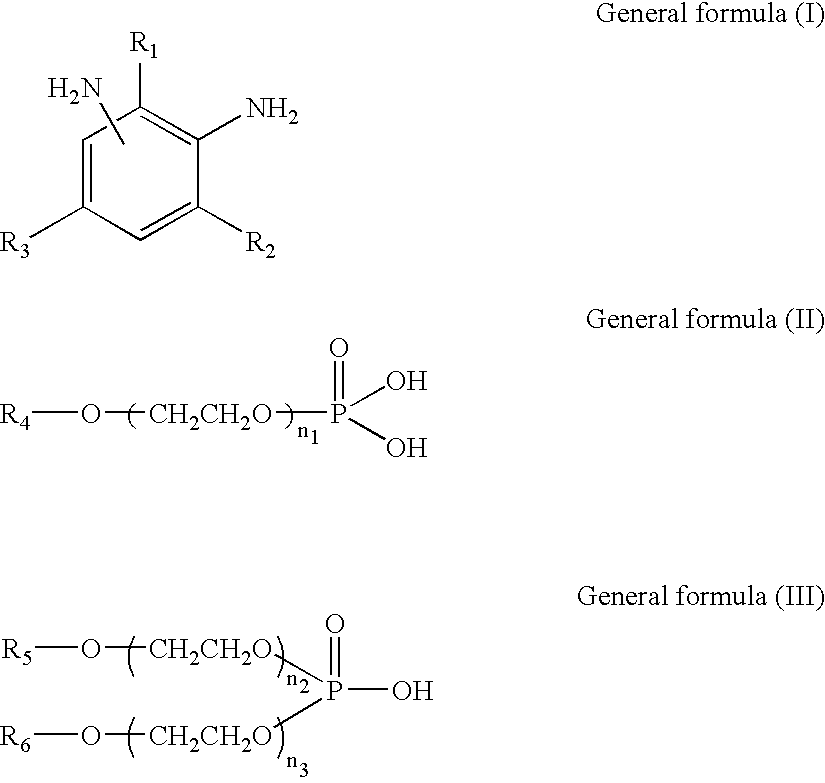

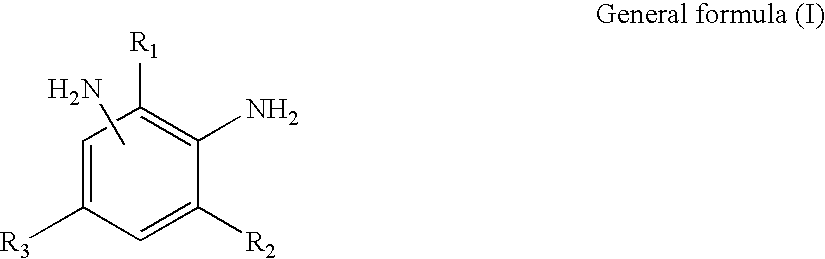

Transparent molded objects, optical member, plastic lens, and processes for producing these

InactiveUS20040151915A1Excellent transparency and mold releasing propertyGood release effectSynthetic resin layered productsCoatingsCarbon numberO-Phosphoric Acid

A transparent molded article comprised of a polymer of the following components (A) and (B), characterized in that said polymer further comprises the following components (C) and (D). A transparent molded article comprised of a polymer of the following components (A) and (B), characterized in that said polymer further comprises the following component (G). An optical member comprising an antireflective layer directly or indirectly on a polyurethane urea polymer substrate, characterized in that said antireflective layer is a multilayer antireflective layer comprising a ½ lambda layer, and said ½ lambda layer comprises a plural high refractive index layers comprising niobium oxide or niobium oxide, zirconium oxide and yttrium oxide, and a layer comprised of silicon dioxide positioned between the high refractive index layers. Component (A): isocyanate terminal prepolymer in the form of a reaction product of an aliphatic diisocyanate having an intramolecular cyclic structure and a diol having an average molecular weight of 300-2,500 Component (B): one or more aromatic diamines denoted by general formula (I). (In general formula (I), R1, R2 and R3 are each dependently any of a methyl, ethyl or thiomethyl group.) Component (C): one or more phosphoric acid monoesters denoted by general formula (II). (In general formula (II), R4 is an alkyl group with a carbon number of 1-10 and n1 is 1 or 2.) Component (D): one or more phosphoric acid diesters denoted by general formula (III). (In general formula (III), R5 and R6 are each dependently an alkyl group with a carbon number of 1-10 and n2 and n3 are 1 or 2.) Component (G): one or more phosphorous peroxide decomposing agents.

Owner:HOYA CORP

Starch adhesive(SSS-85)

The starch adhesive SSS-85 has corn starch and water as main components and contains also stabilizer, oxidant, terminating agent, catalyst, etc. The adhesive is chemically modified neutral grafted starch and is specially for coating pigment. Compared with conventional starch, the present invention has less retrogradation and high compatibility, and is suitable for compounding pigment paint with high solid content and low viscosity. The present invention is suitable for painting various paper products.

Owner:泰州市华光金属制品有限公司

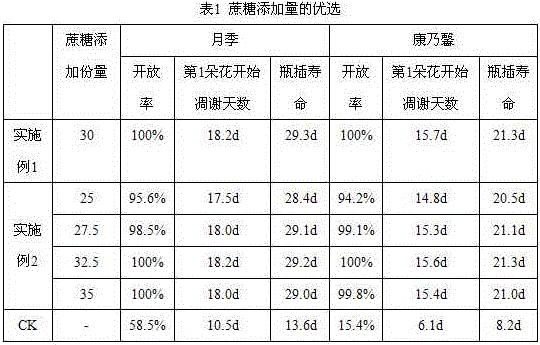

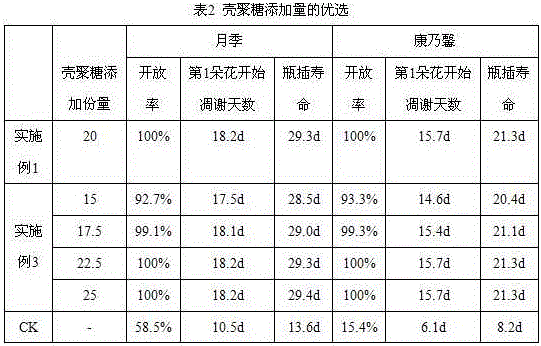

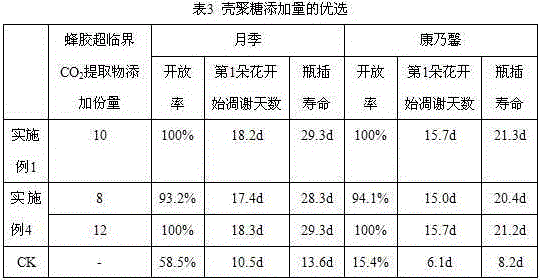

Fresh flower preservative

InactiveCN106259308ASmall reductionAppropriate concentrationBiocideDead plant preservationSucrosePropolis

The invention provides a fresh flower preservative. The fresh flower preservative comprises the following components in parts by mass: 25 to 35 parts of cane sugar, 15 to 25 parts of chitosan, 8 to 12 parts of propolis supercritical CO2 extracts, 4 to 6 parts of natamycin, 1.6 to 2.0 parts of citric acid, 0.8 to 1.2 parts of salicylic acid, 0.6 to 0.8 part of boric acid, 0.6 to 1.0 part of vitamin C, 0.5 to 0.7 part of vitamin E, 60 to 100 parts of traditional Chinese herbal medicine ethanol extracting liquid and the balance of ultrapure water, wherein the total parts are 1000 parts. The fresh flower preservative provided by the invention has a reasonable formula, safe and environmentally-friendly components, a good nutrition effect and an excellent broad-spectrum antibacterial effect, can effectively inhibit damage to fresh flowers by various microorganisms, greatly prolongs the freshness-retaining period of the fresh flowers, has significant color-protecting and color-improving effects, is simple in preparation method, and is simple and convenient to operate during use.

Owner:LIANYUNGANG XIUJING LANDSCAPING ENG CO LTD

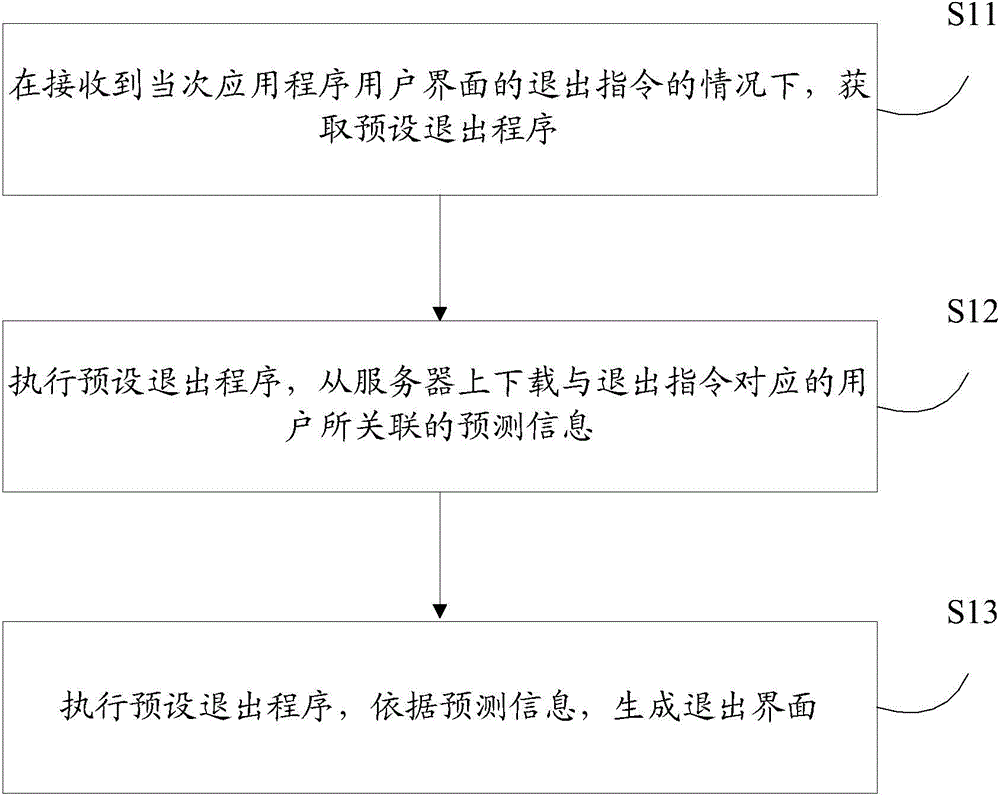

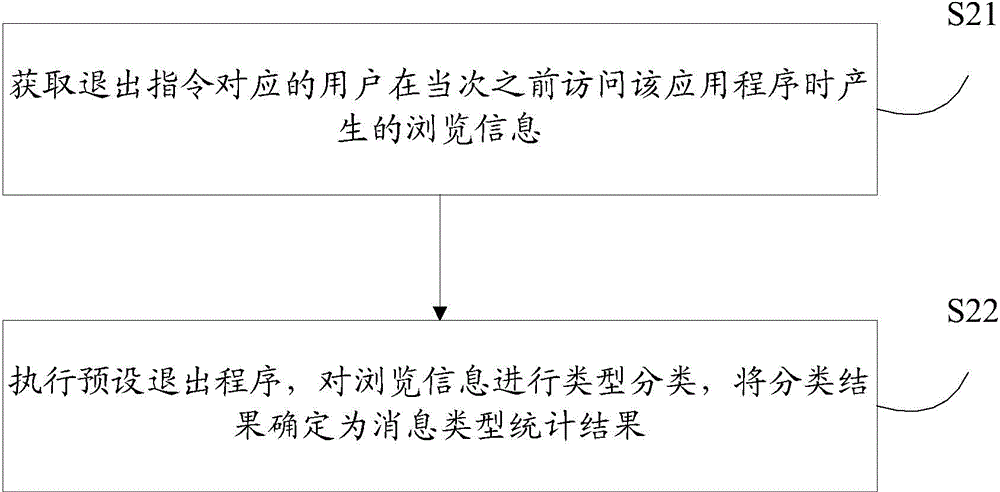

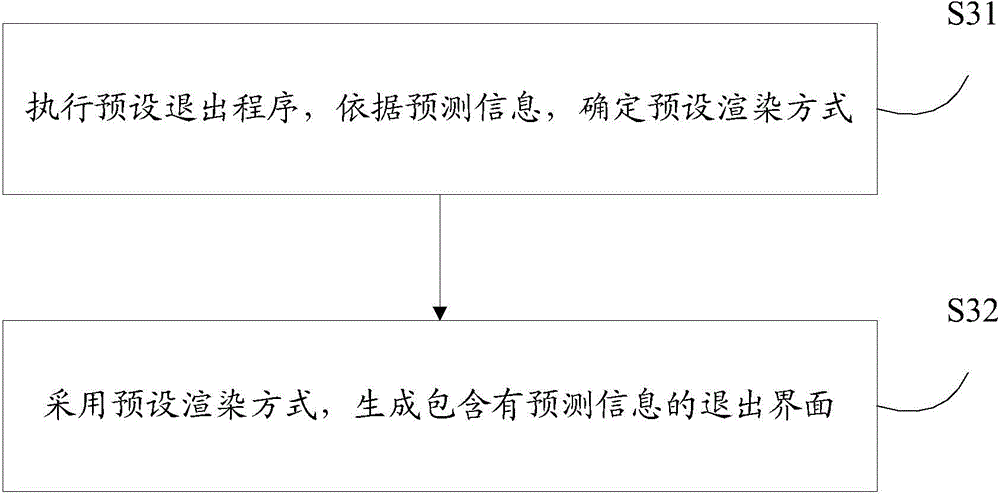

Interface exit display method and device

InactiveCN103605549ASmall reductionReduce the chance of leaving the appProgram loading/initiatingTransmissionTraffic volumeInformation type

The invention provides an interface exit display method. The method includes: acquiring a preset exit program when receiving an exit command for an application user interface at the present time; executing the preset exit program to download user-associated prediction information corresponding to the exit command from a server; executing the preset exit program, and generating an exit interface according to the prediction information. The prediction information is generated by the server and related to an information type statistical result. The information type statistical result which is a sorting result is obtained by executing the preset exit program and sorting the types of view information generated when a user corresponding to the exit command accesses an application before the present time. The exit interface includes the prediction information and an exit acknowledgment message. The interface exit display method has the advantages that chances of the user leaving the application are slimmed, reduction in user's traffic is reduced, and reduction in website information is reduced.

Owner:随身云(南京)信息技术有限公司 +1

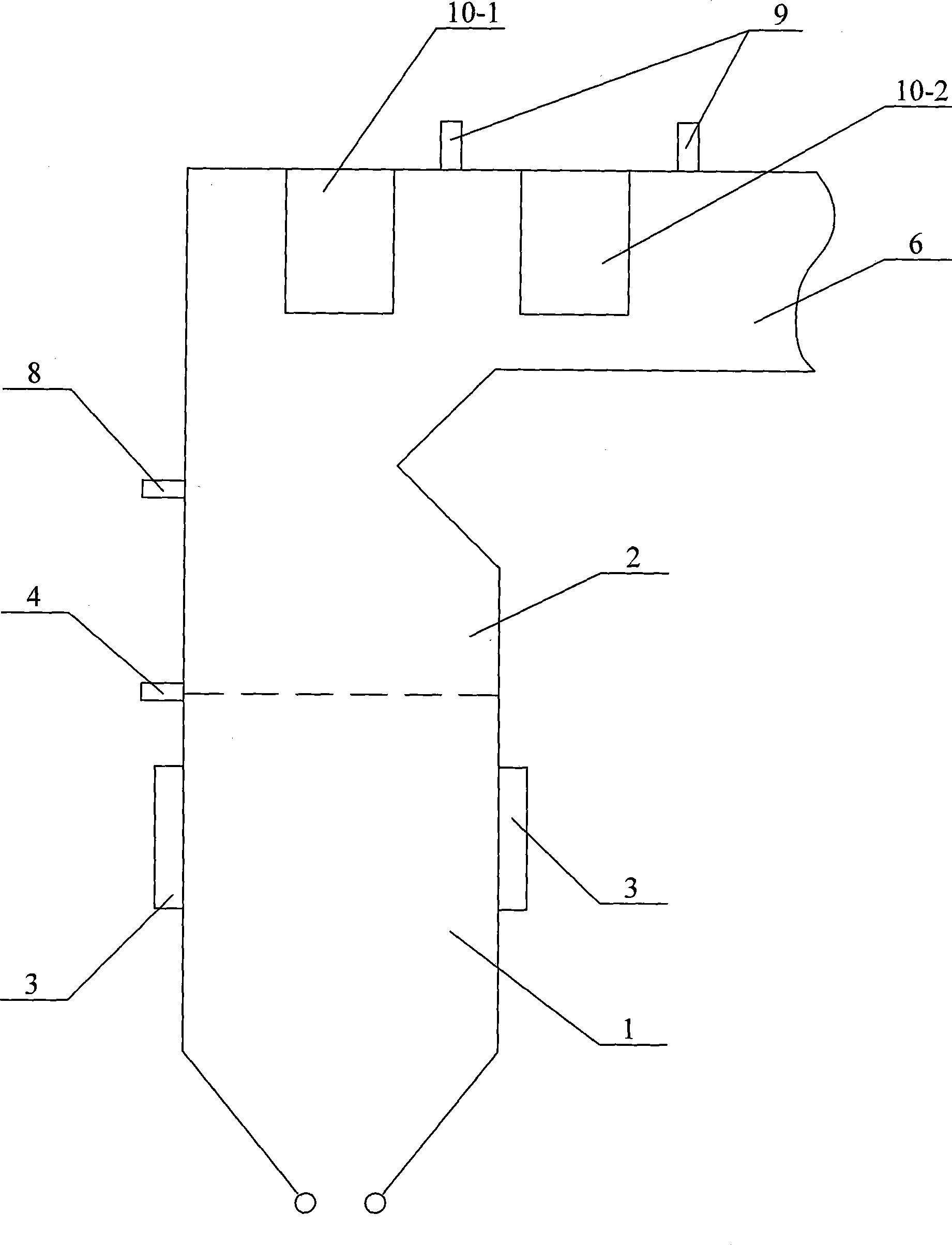

Lignite low nitrogen oxide combustion method with dry-type amino reductive delivery

InactiveCN101482263AEmission reductionImprove combustion efficiencyAir supply regulationDispersed particle separationLow nitrogenSlag

The invention provides a combustion method for brown coal with less nitrogen oxide by dry-type transportation of an amino group reducer and relates to the combustion method for brown coal. The method solves the problems that slag bonding is easy to appear in the boiler combustion of the brown coal by adopting air fractional combustion technology, a catalyst is needed, system investment is huge and operating cost is high in the boiler combustion of the brown coal by adopting selective catalytic reduction technology and denitration efficiency is low and thermal efficiency of the boiler is affected by evaporation of reducer solution in the boiler combustion of the brown coal by adopting selective non-catalytic reduction technology. A boiler with the furnace being divided into a primary combustion zone (1) and a burnout zone (2) from bottom to top is adopted in the boiler combustion method and amino group reducer particles and solution are sprayed grade by grade during the combustion process of the brown coal. By the two methods of the invention, the discharge of the nitrogen oxide can be reduced by more than 60% and the combustion efficiency of the brown coal is up to more than 98%. By the two methods, no slag bonding appears during the combustion of the brown coal, no catalyst is needed and the operating cost is only around 30% of the operating cost of the SCR method. The effect of the method on the thermal efficiency of the boiler is less than 0.5%.

Owner:HARBIN INST OF TECH

Starch adhesive(TSS-85)

The starch adhesive TSS-85 has corn starch and water as main components and contains also stabilizer, oxidant, terminating agent, catalyst, etc. The adhesive is chemically modified neutral grafted starch and is specially for coating pigment. Compared with conventional starch, the present invention has less retrogradation and high compatibility, and is suitable for compounding pigment paint with high solid content and low viscosity. The present invention is suitable for painting various paper products.

Owner:泰州市华光金属制品有限公司

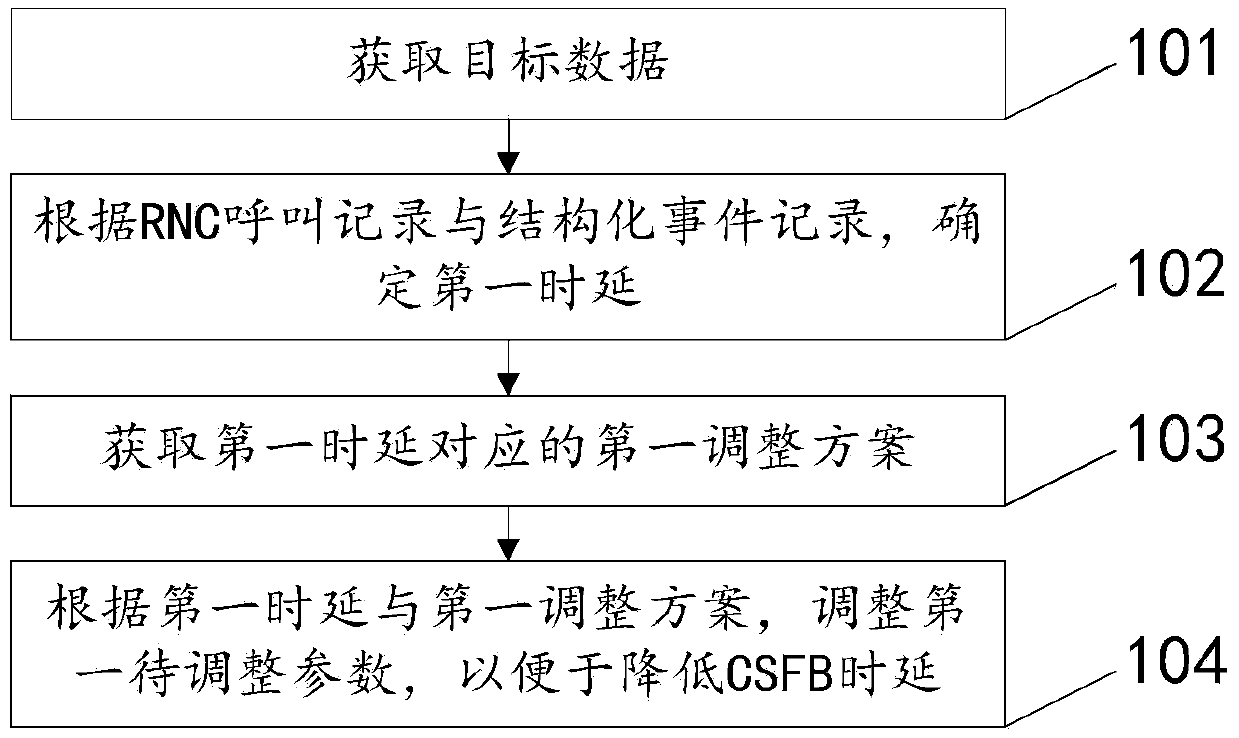

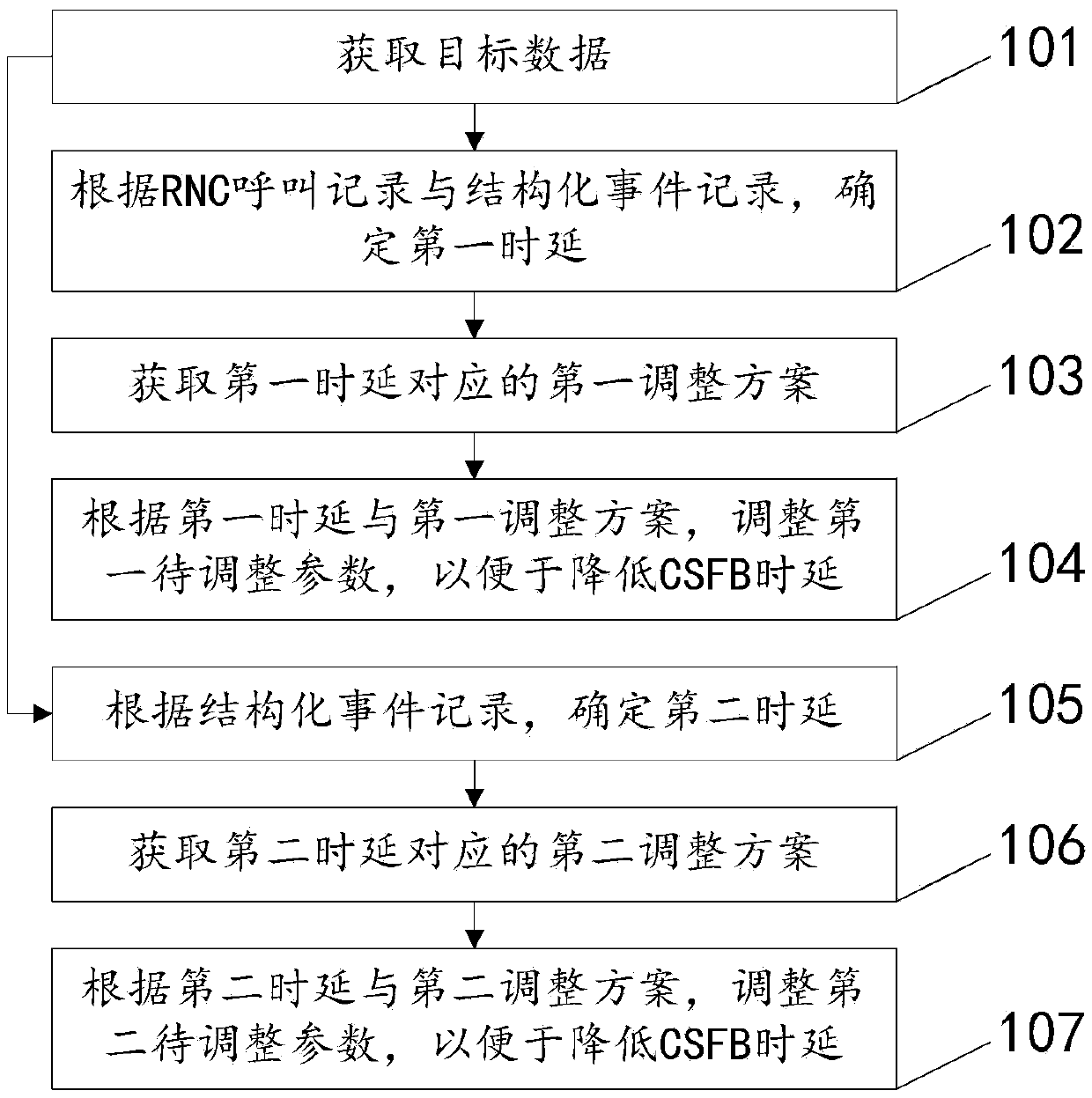

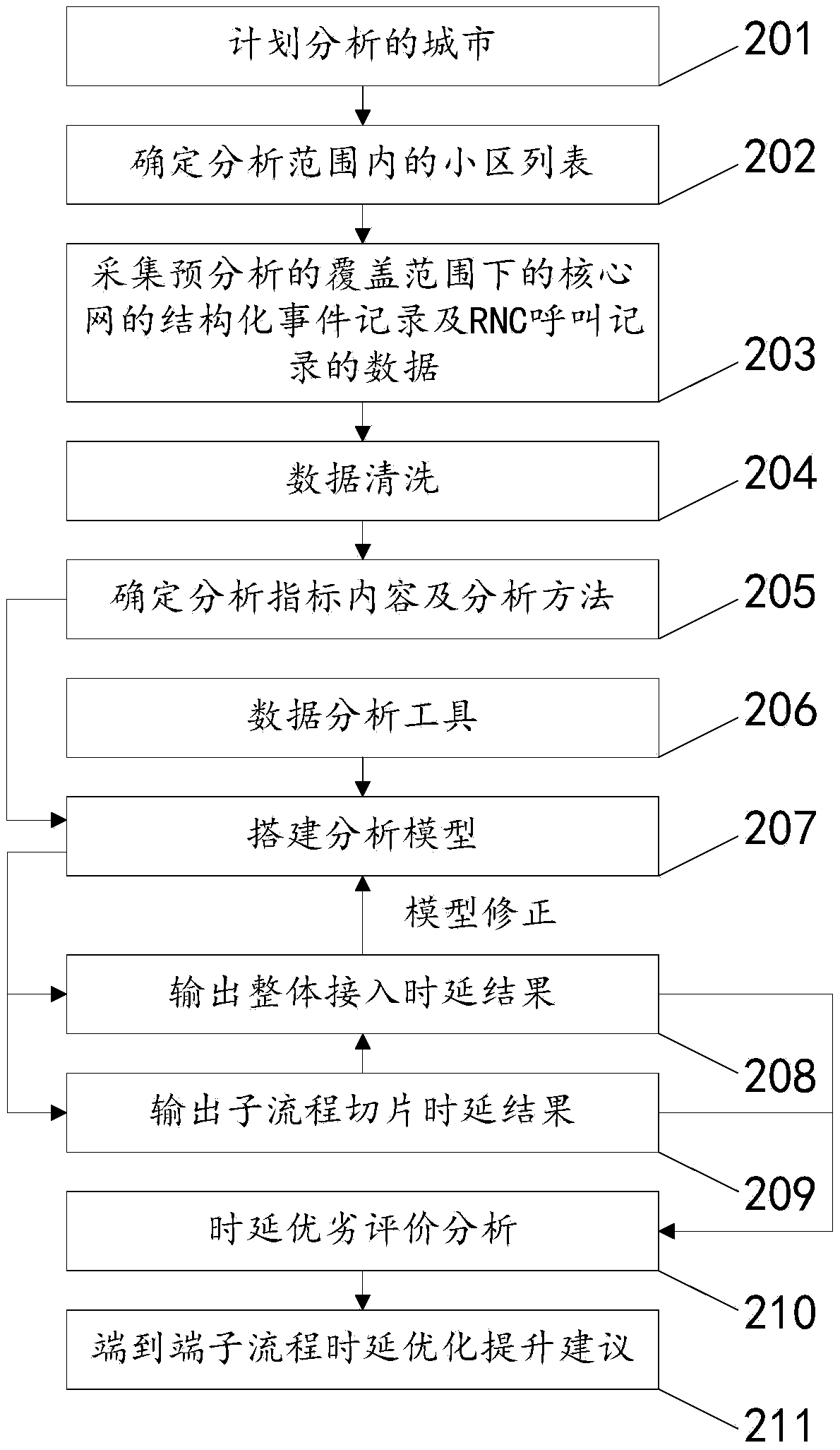

Method and device for reducing CSFB delay

ActiveCN105376765AReduce latencySmall reductionSynchronisation arrangementCore networkReal-time computing

The embodiment of the invention discloses a method and a device for reducing CSFB delay, which relate to the technical field of communication and can solve a problem that methods for reducing CSFB delay are relatively single. The method provided by the embodiment comprises the following steps of: acquiring target data, wherein the target data comprises RNC call record of a wireless side and structured event record of a core network; determining the first delay according to the RNC call record and the structured event record; obtaining a first adjustment scheme corresponding to the first delay, wherein the first adjustment scheme comprises a first to-be-adjusted parameter which is in the wireless side or the core network and corresponds to each delay parameter in the first delay, and adjustment direction of the first to-be-adjusted parameter; and adjusting the first to-be-adjusted parameter according to the first delay and the first adjustment scheme so as to reduce the CSFB delay. The method and the device provided by the invention are suitable for optimizing the CSFB delay.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

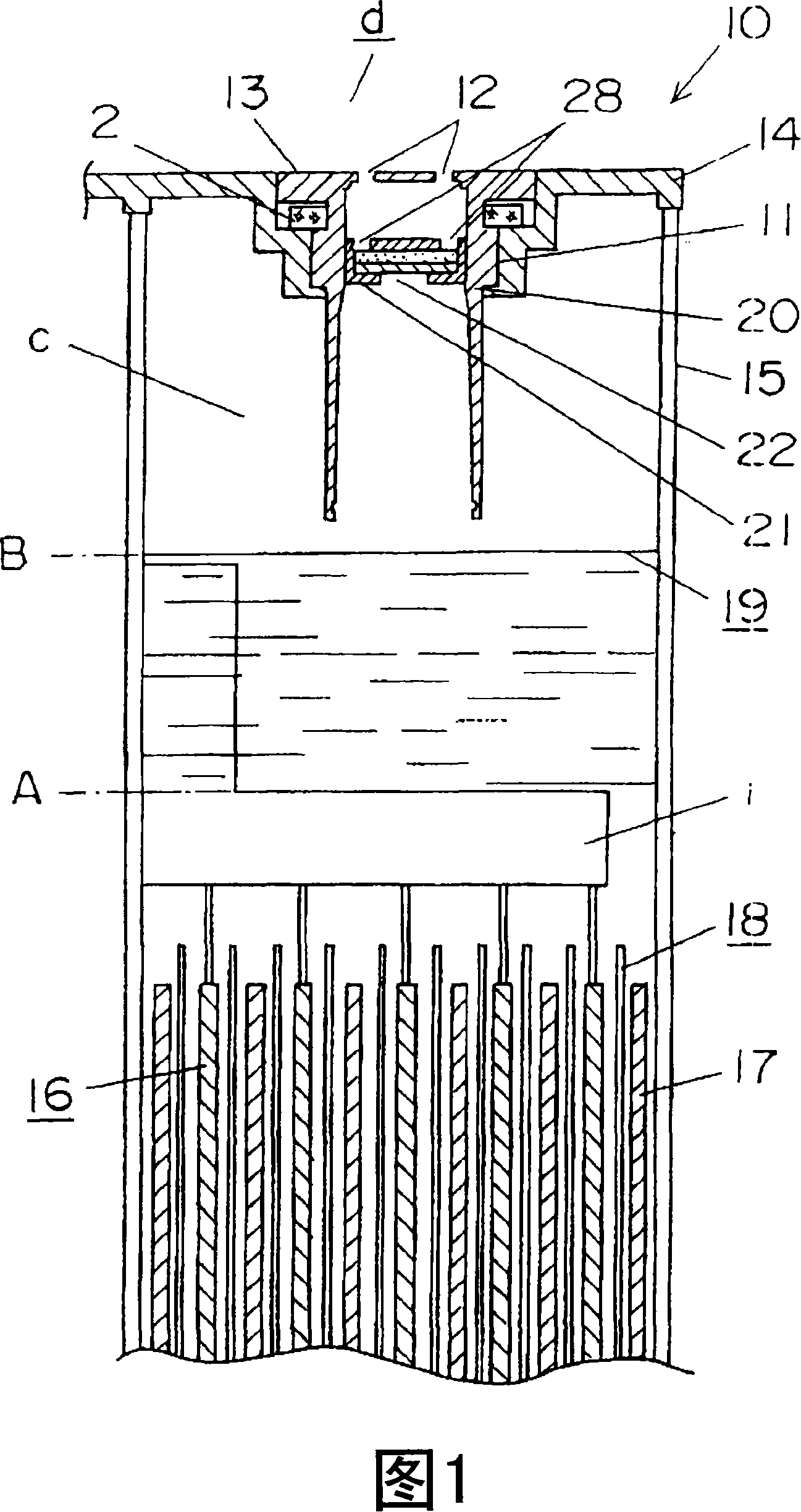

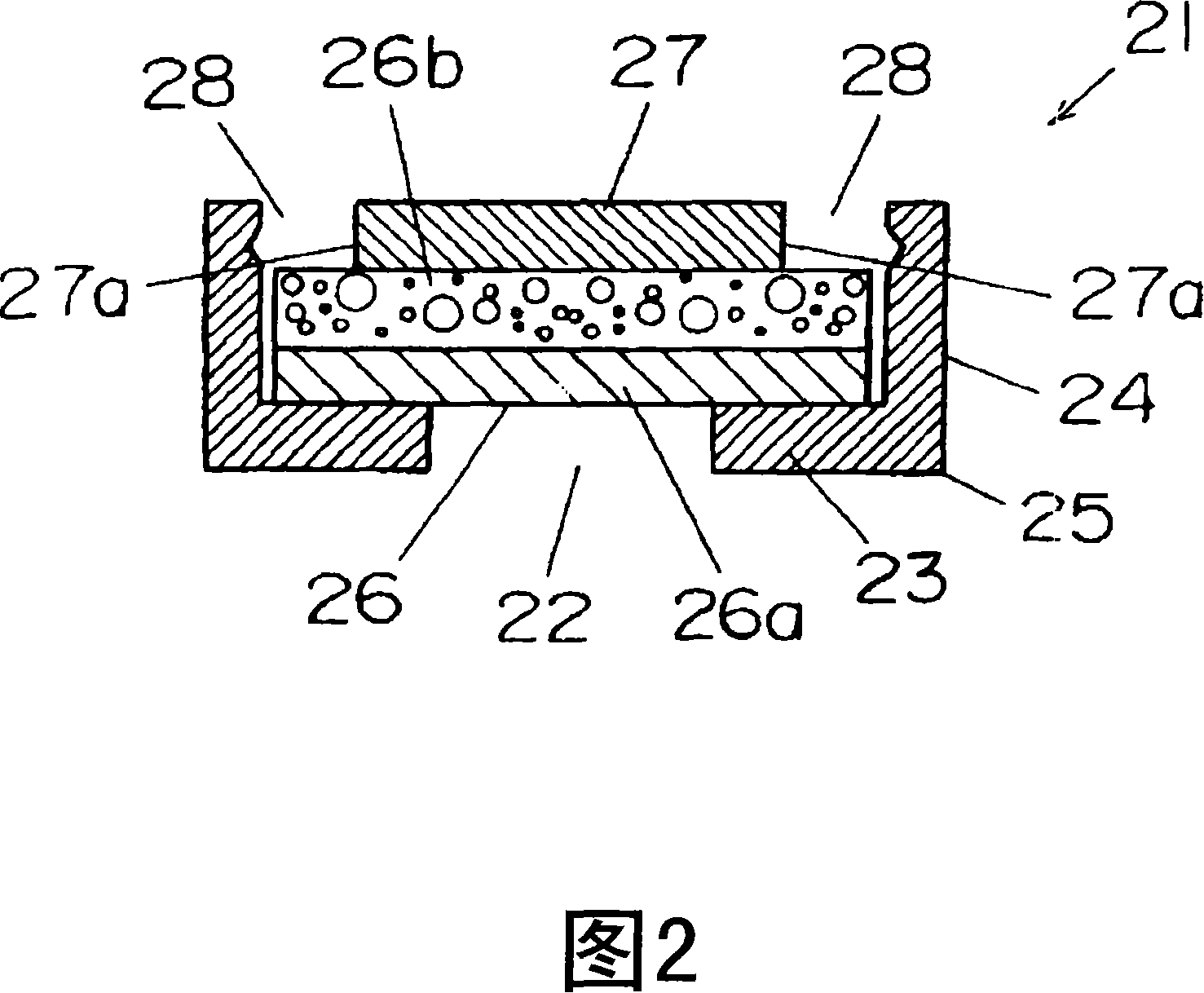

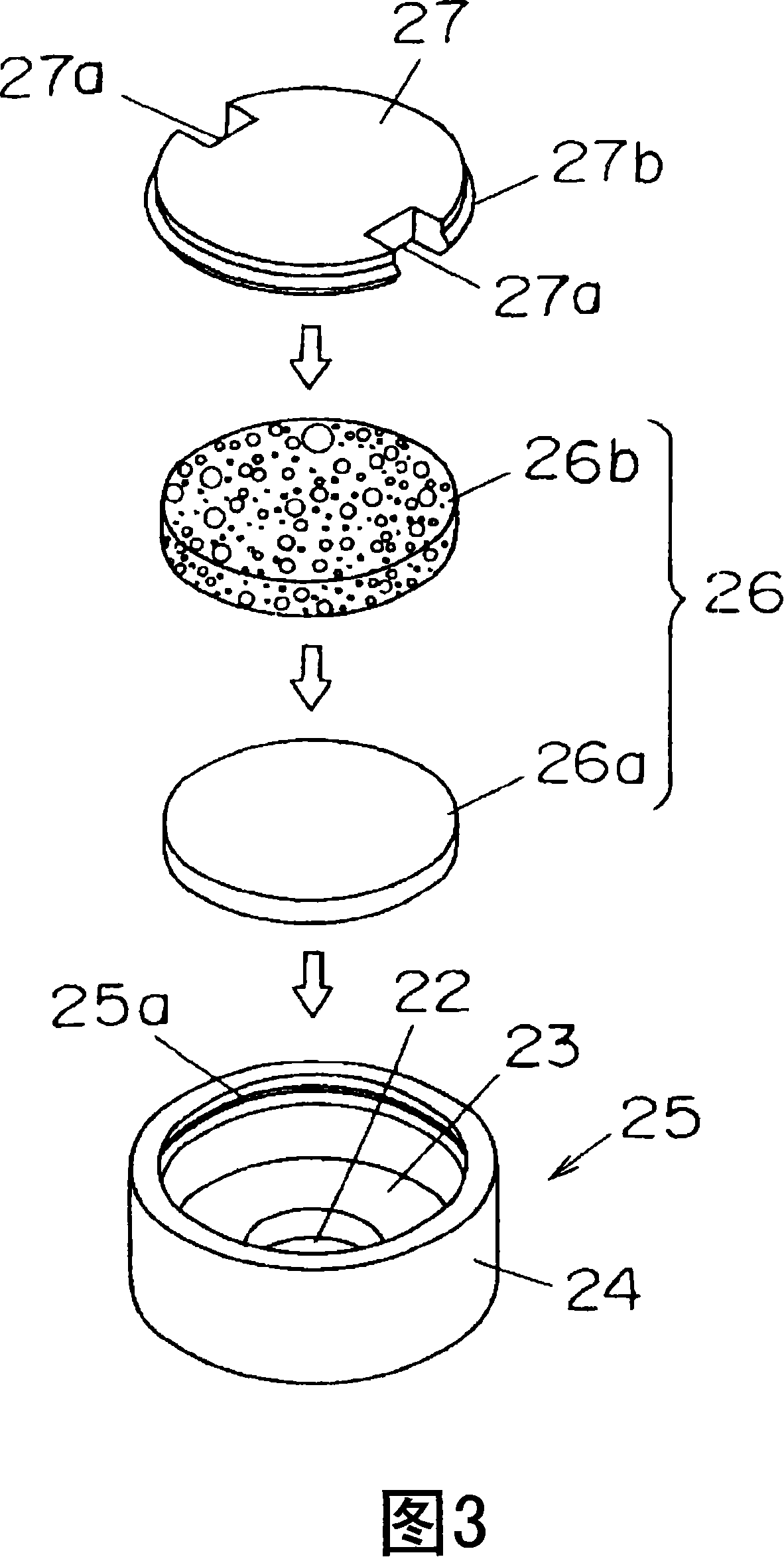

Lead storage battery

InactiveCN101151744AInhibit dissipationReduce the number of piecesFinal product manufactureElectrode carriers/collectorsInternal pressureEngineering

A liquid-inlet cap (13) is installed in a liquid inlet (11) provided in a battery casing, the liquid-inlet cap (13) having a ventilating hole (12) for expelling a gas from the inside of a battery to the outside of the battery. A control valve section (21) is installed inside a cylindrical body (20) of the liquid-inlet cap (13) separately from the cylindrical body (20) and responds to the internal pressure of the battery to form a ventilating passage from a vent hole (22) provided on one end to a ventilating opening (28) provided on the other end.

Owner:PANASONIC CORP

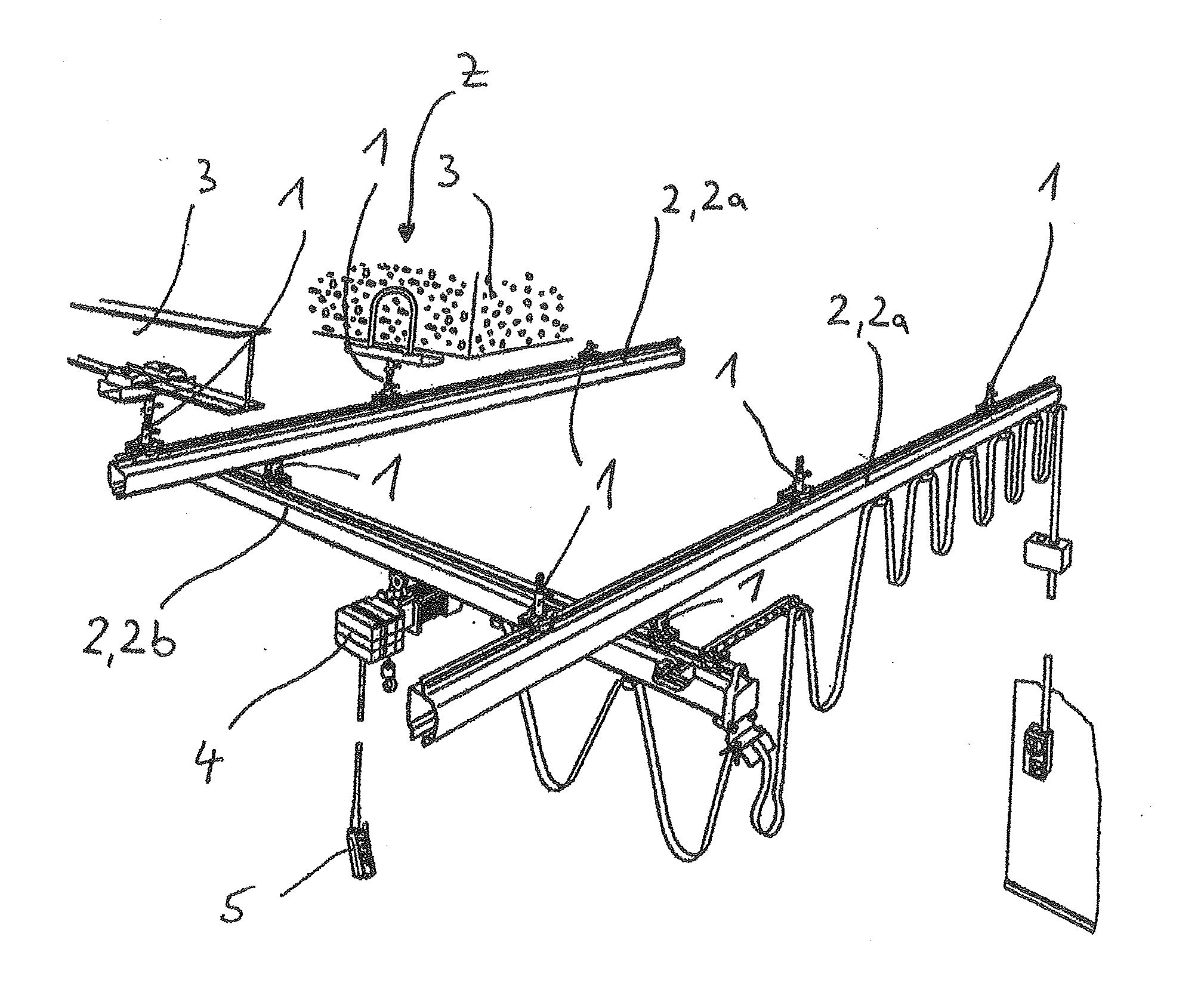

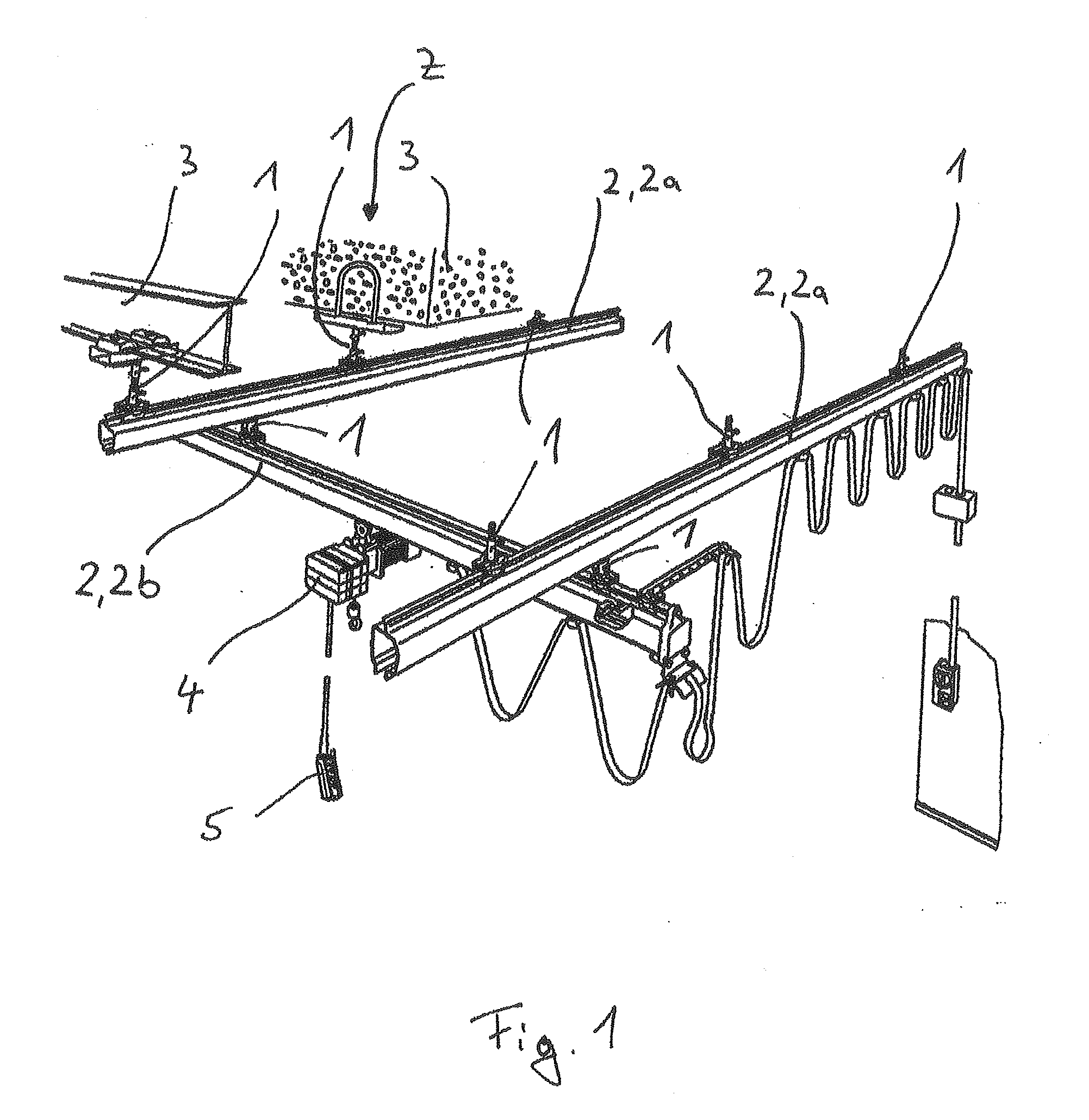

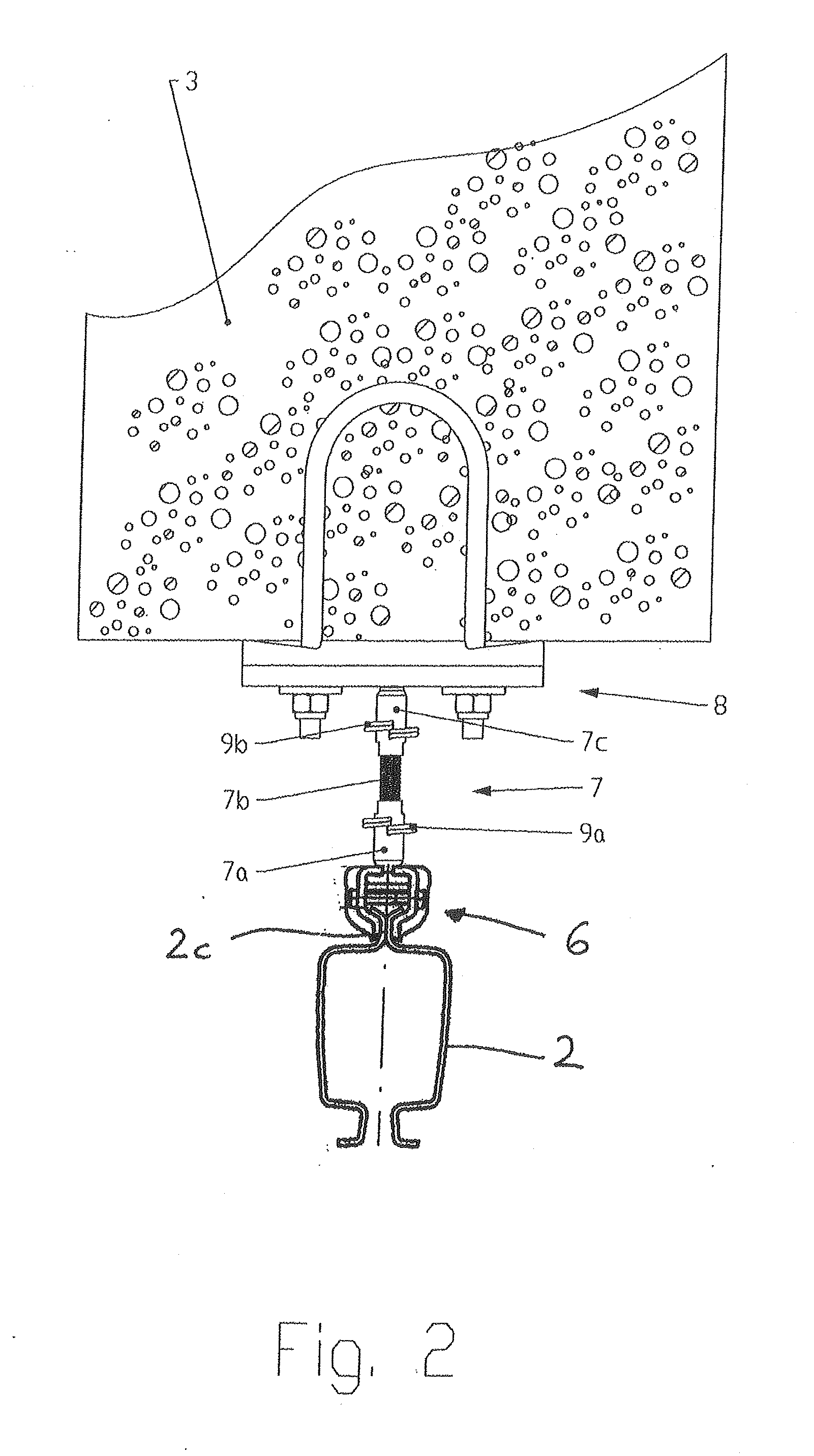

Device for suspending a rail, in particular a rail of an overhead conveyor or lifting gear

ActiveUS20130153374A1Simplified and secure assemblySmall reductionConveyorsBallastwayEngineeringMechanical engineering

A suspending device for a rail, in particular a rail of an overhead conveyor or lifting gear, with a tensile element, which comprises a threaded rod and at least one connecting part that is screwed to the latter, and with a securing element, which secures the screw connection between the threaded rod and the connecting part against loosening. The suspending device for a rail, in particular a running rail of a suspended conveyor or lifting gear, allows simplified and secure mounting in that the securing element engages in a groove with a pin part in the assembled state, with the groove being disposed in the threaded rod.

Owner:KONECRANES GLOBAL

Light shielding member, a line head and an image forming apparatus using the line head

A line head, includes: a head substrate that includes a plurality of light emitting element groups as groups of light emitting elements; a lens array that includes a plurality of lenses each of which faces the corresponding light emitting element group in a first direction; and a light shielding member that is disposed between the head substrate and the lens array and includes a plurality of light shielding plates which are arranged side by side in the first direction while defining a space layer therebetween, wherein each of the plurality of light shielding plates is provided with a plurality of light guide holes penetrating in the first direction and facing the plurality of light emitting element groups in the first direction respectively, the plurality of light guide holes facing each of the light emitting element groups are arranged in the first direction respectively to form a plurality of light guide portions, and lights from the plurality of light emitting element groups are incident on the plurality of lenses through the plurality of light guide portions respectively.

Owner:SEIKO EPSON CORP

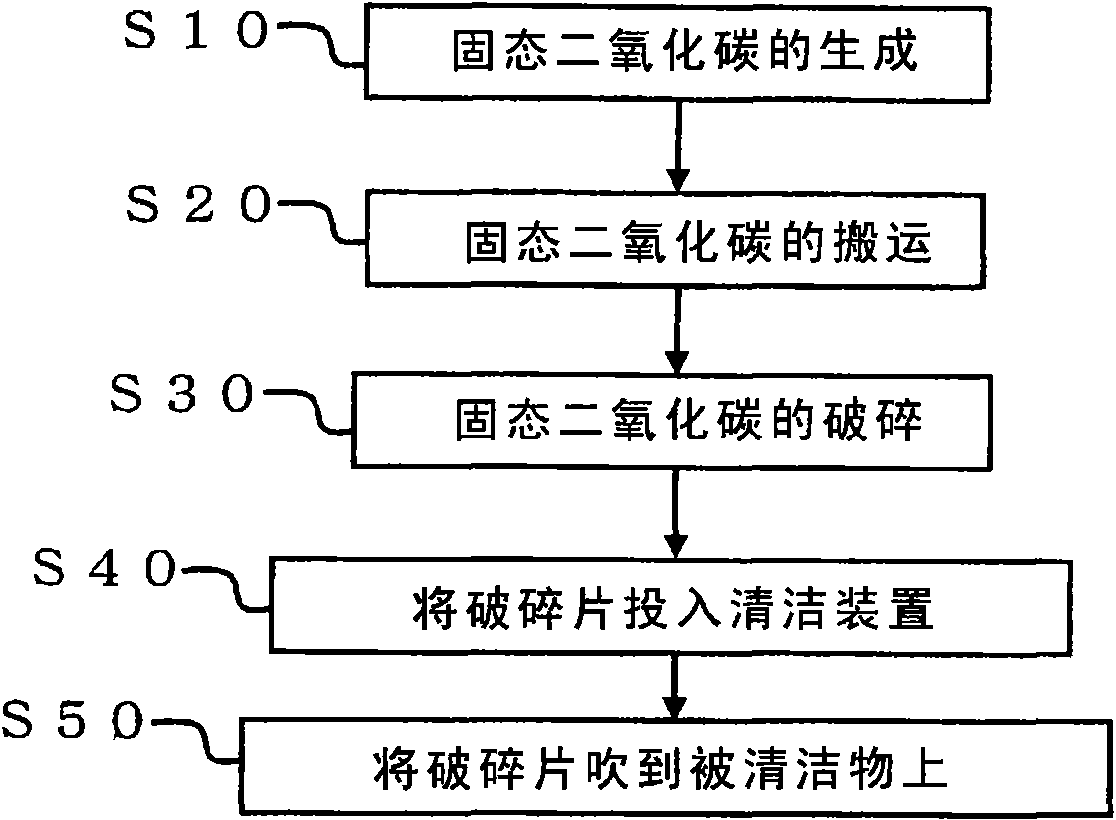

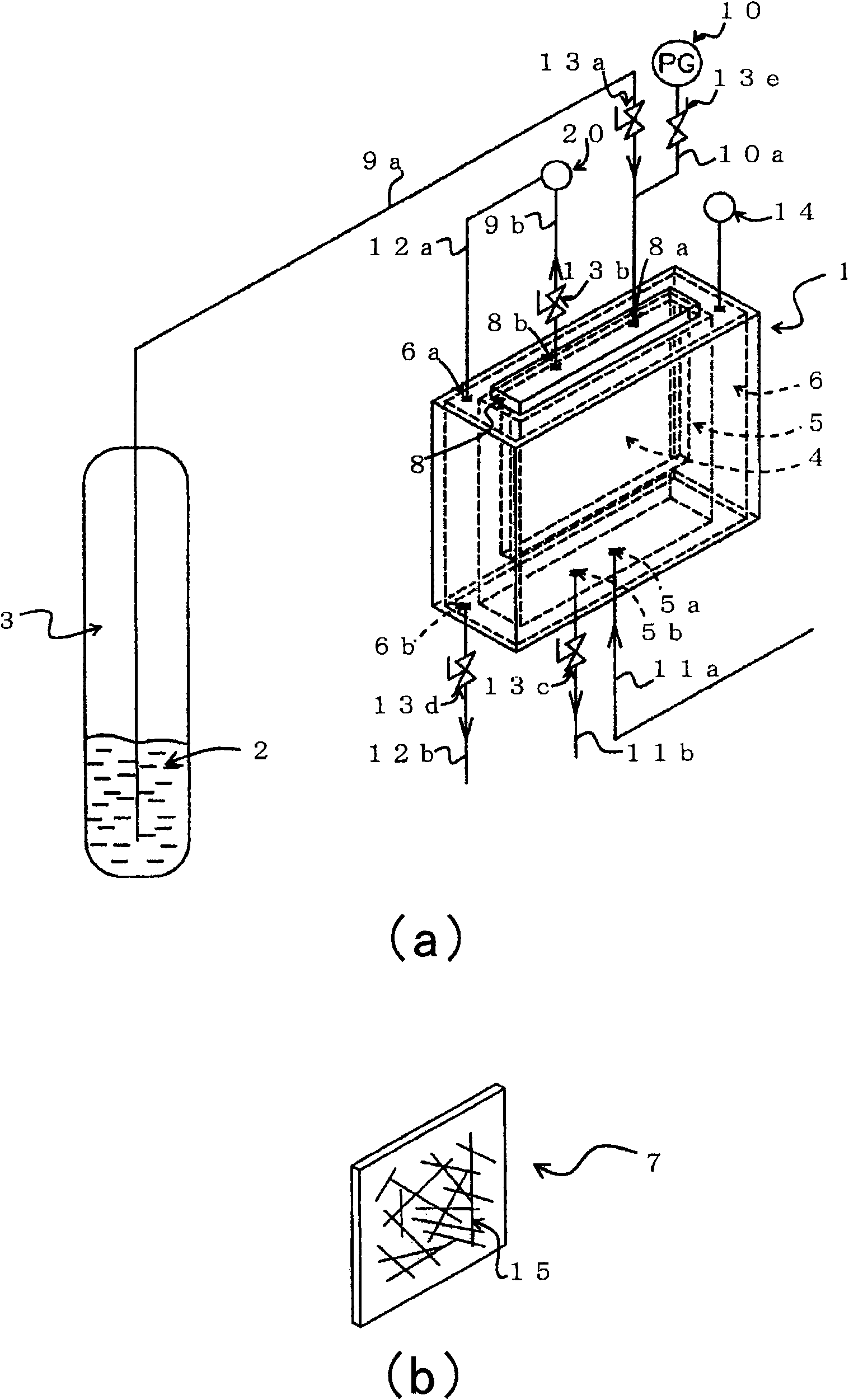

Blast cleaning process, and method and apparatus for producing solid carbon dioxide used in the same

InactiveCN101801609ASmall reductionLow costCarbon compoundsAbrasion apparatusHardnessSolid carbon dioxide

Disclosed is a blast cleaning process wherein cleaning power can be adjusted by changing hardness, shape or size of solid carbon dioxide which is used as shot. Also disclosed are a method and an apparatus for producing solid carbon dioxide to be used in the blast cleaning process. The blast cleaning process comprises a step of producing a plate-like solid carbon dioxide (7) crushed pieces of which are used as shot (step S10); a step of conveying the plate-like solid carbon dioxide (7) into a work site (step S20); a step of crushing the plate-like solid carbon dioxide (7) at the work site or the like (step S30); a step of introducing the crushed pieces into a cleaning apparatus (blast apparatus) (step S40); and a step of performing cleaning by blasting the crushed pieces onto an object to be cleaned (step S50).

Owner:TAKEWA KOUGYOU KK

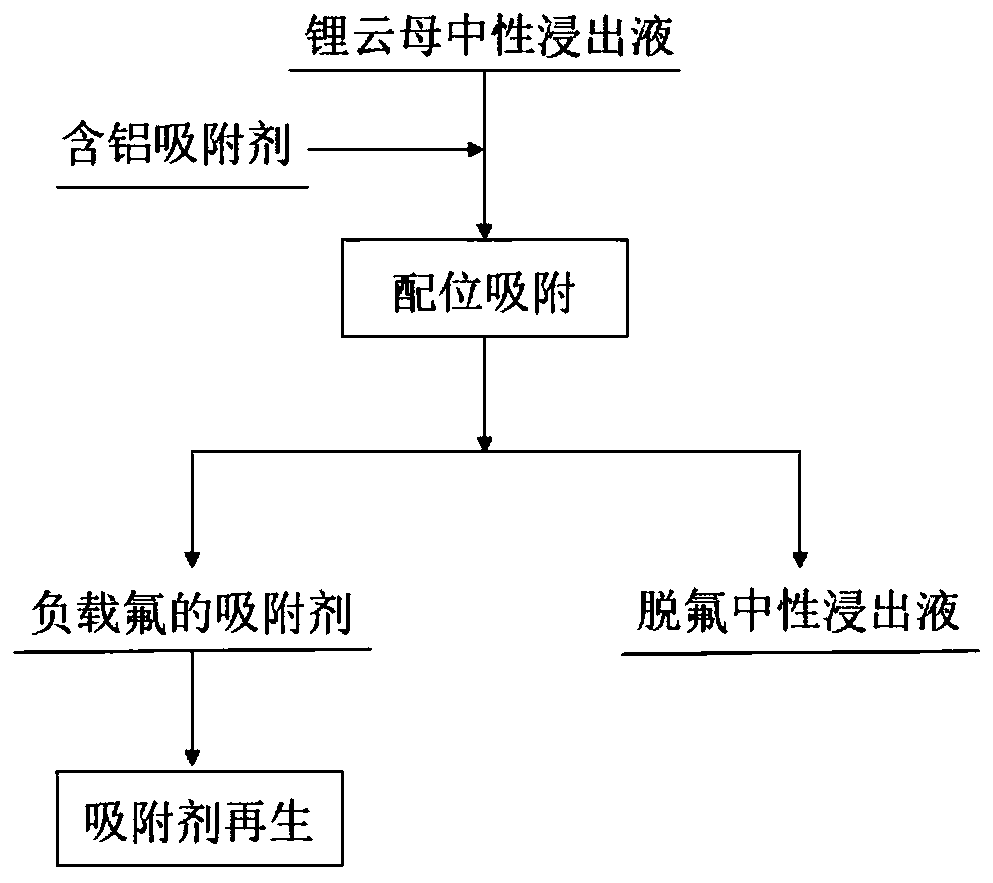

Method for removing fluorine in lithium-mica ore neutral leaching solution by using aluminum-containing adsorbents

ActiveCN110205502ASolve the problem of excessive fluorine contentWon't happenOther chemical processesCombustible gas purificationSorbentLithium carbonate

The invention relates to a method for removing fluorine in a lithium-mica ore neutral leaching solution by using aluminum-containing adsorbents, and belongs to the technical field of rare metal hydrometallurgy. The method disclosed by the invention comprises the following steps that the PH value of the lithium mica leaching solution is adjusted to 4.0-9.5 at 10-35 DEG C; appropriate amount of aluminum-containing adsorbents is added, so that the concentration of aluminum-containing adsorbents reaches 28-32 g / L, and the aluminum-containing adsorbents are continuously stirred for 15-45 min; thefluorine-loaded aluminum-containing adsorbents solid and a defluorinated lithium mica leaching solution are obtained through the solid-liquid separation; and the PH value of the aluminum-containing adsorbents is strictly controlled to 5.8-6.2 during preparation of the aluminum-containing adsorbents. The fluorine removal agent prepared by the method can effectively reduce the fluorine content in the lithium mica ore leaching liquid to reach the standard, the quality of the lithium carbonate product is directly improved, the cost is low, the method has considerable social and economic values; meanwhile, the aluminum-containing adsorbents are simple to regenerate, and the performance of the regenerated product is far superior to that of an existing product.

Owner:CENT SOUTH UNIV +1

Display device with luminance variation control unit

ActiveUS8531383B2Avoid flickeringDecrease in luminanceTelevision system detailsStatic indicating devicesDisplay deviceComputer vision

Provided is a display device capable of producing an image of excellent quality with reduced flicker and little reduction in luminance, the display device including: a backlight having light sources such as LED devices arranged two-dimensionally, each of which may be individually modulated in luminance; a moving velocity detection unit VD1 (109) for detecting a moving velocity of an object in a video (for example, moving velocity of a foreground); and a luminance variation control unit (113) for automatically controlling luminance variations of the LED devices for each frame, in accordance with the moving velocity.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

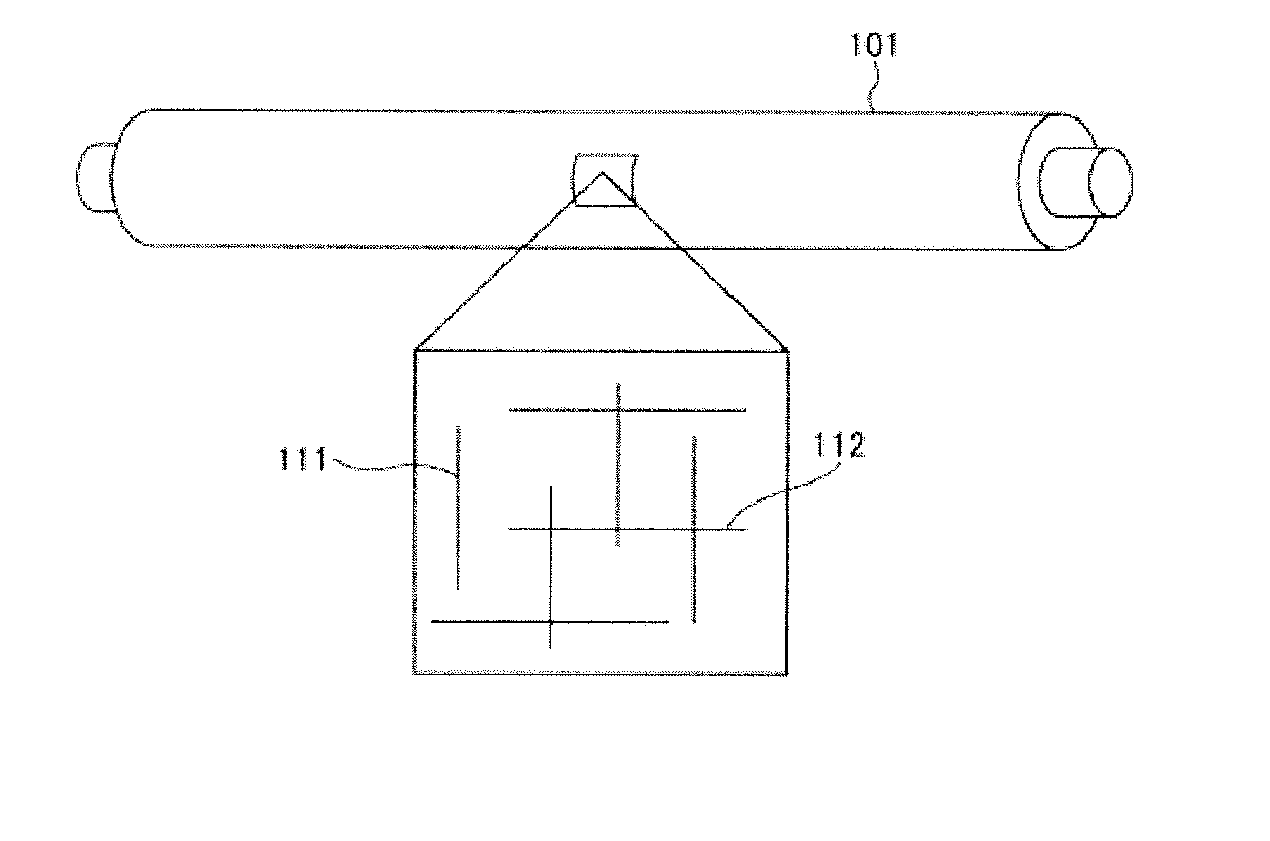

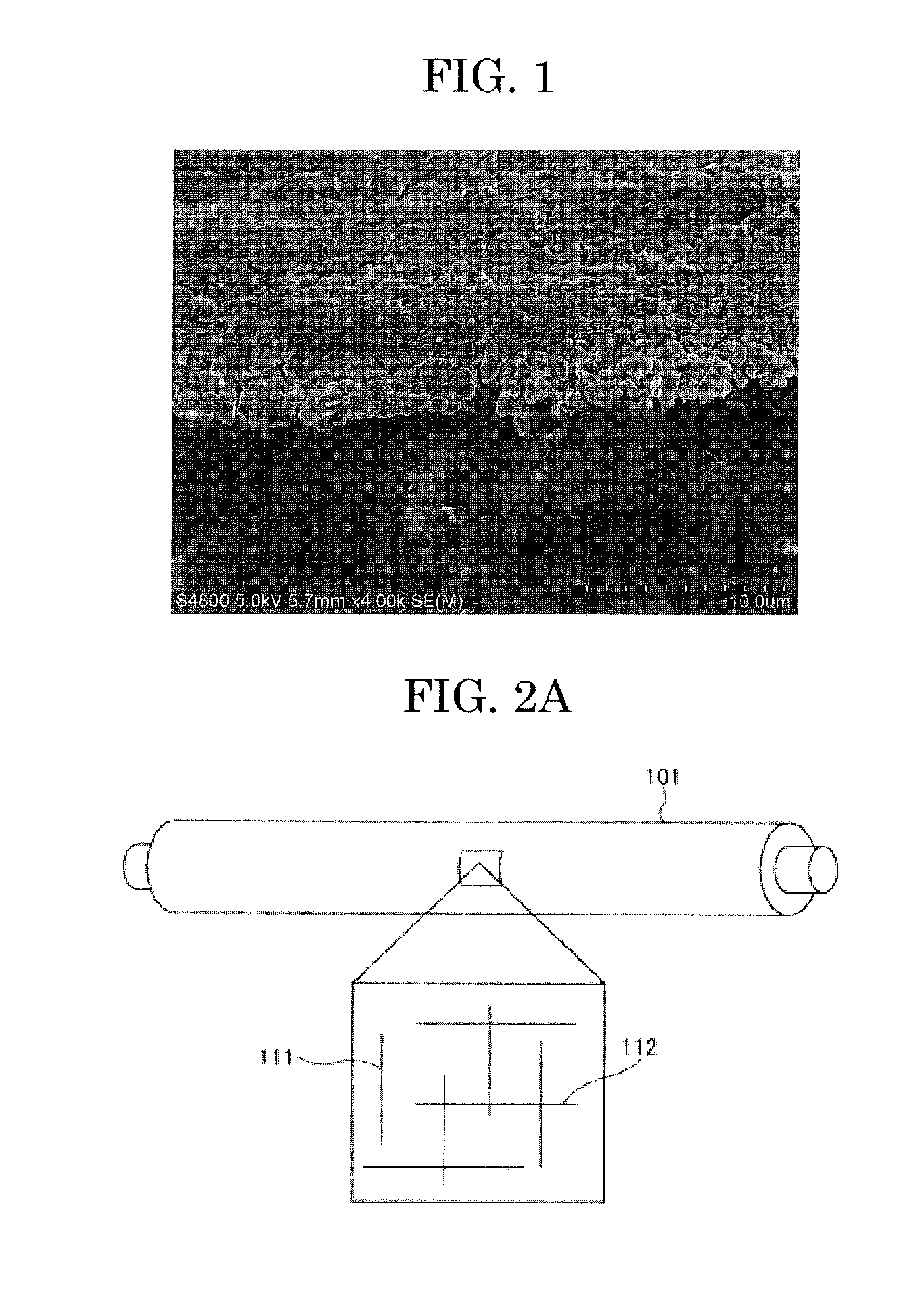

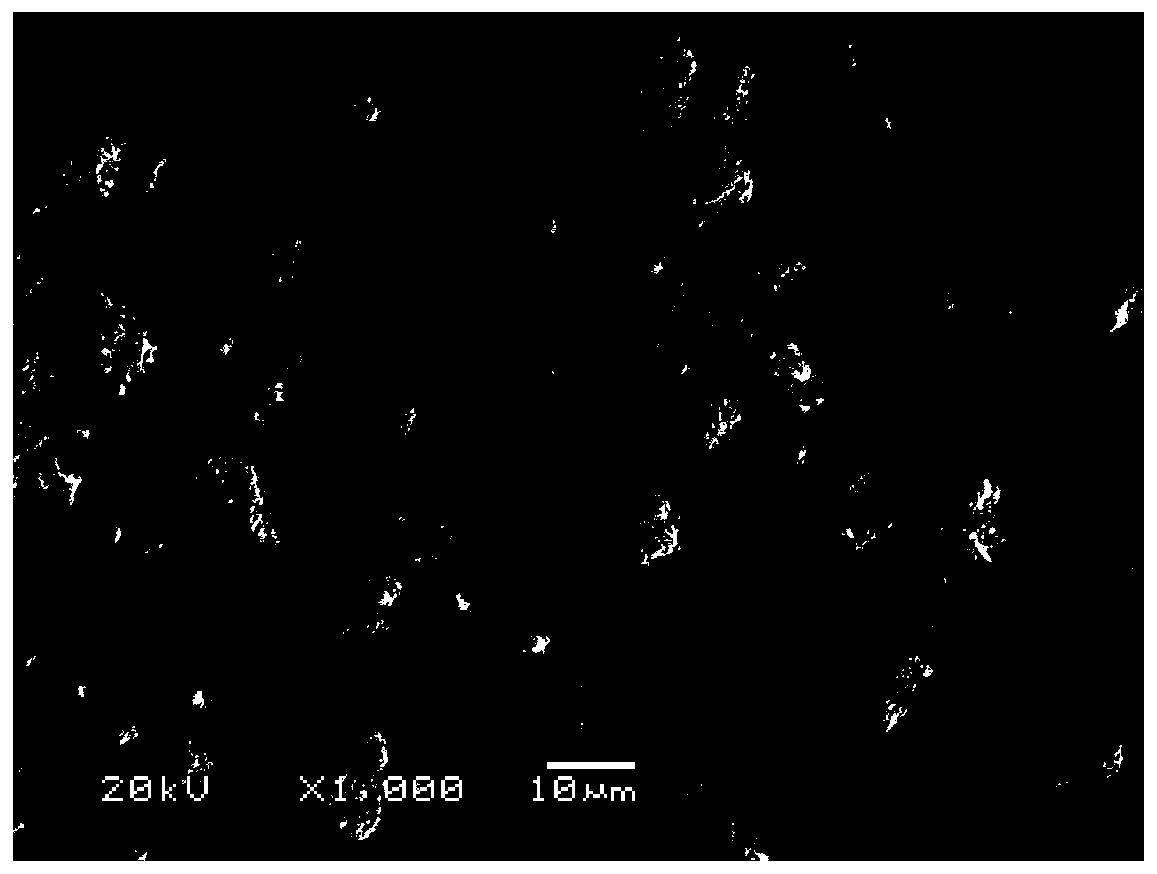

Electrolytic copper foil and production method of electrolytic copper foil

InactiveUS20140318973A1High tensile strengthSmall reductionPhotography auxillary processesChromatisationElectrolysisMeasurement point

The present invention provides an electrolytic copper foil that has a high normal tensile strength, a low decrease in tensile strength after a thermal history, and a low concentration of impurities in the copper foil and a method for producing the copper foil. Specifically, the electrolytic copper foil in which a sulfur concentration of the copper foil is not less than 10 ppm by mass but no more than 50 ppm by mass, wherein when lattices with a spacing of 10 nm in a STEM image observed with a scanning transmission electron microscope at a magnification of 1 million times are formed and intersections of each lattice are used as a measurement point for determining a sulfur concentration, there is a measurement point at which the sulfur concentration is higher as compared to the sulfur concentration of the copper foil.

Owner:JX NIPPON MINING & METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com