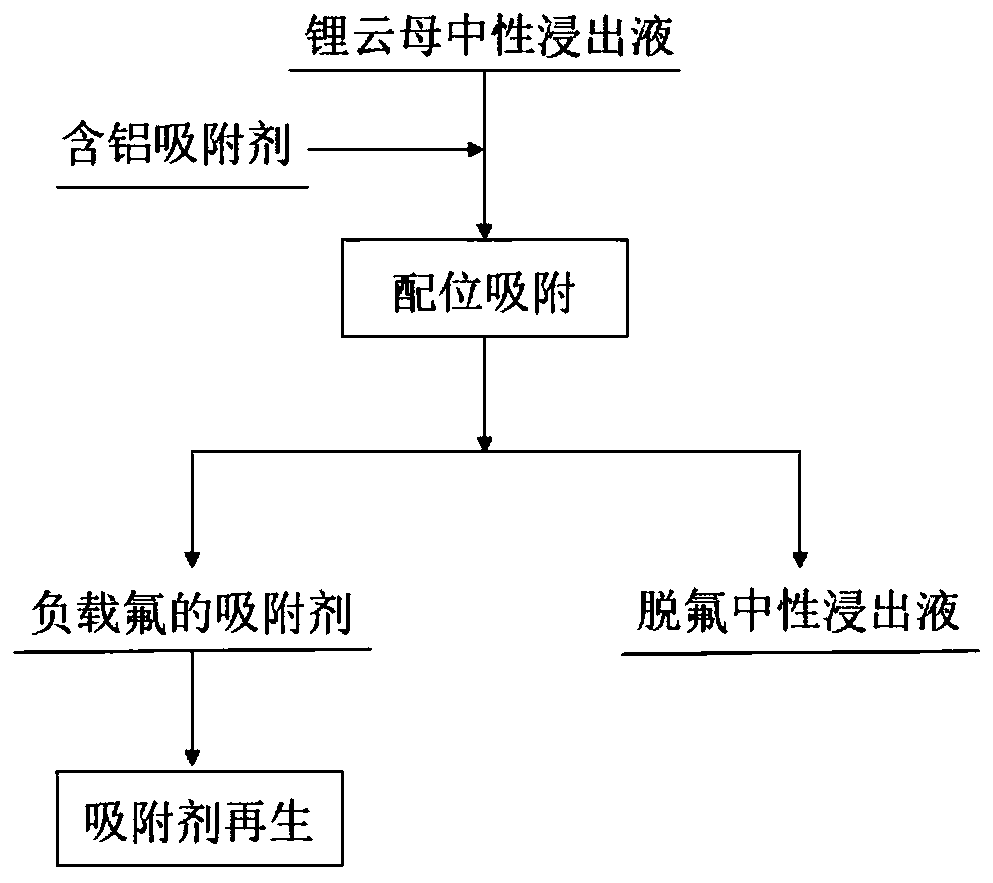

Method for removing fluorine in lithium-mica ore neutral leaching solution by using aluminum-containing adsorbents

A technology of adsorbent and lepidolite, which is applied in the direction of separation method, chemical instrument and method, process efficiency improvement, etc., to achieve the effect of reducing cost, avoiding corrosion, and simple regeneration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

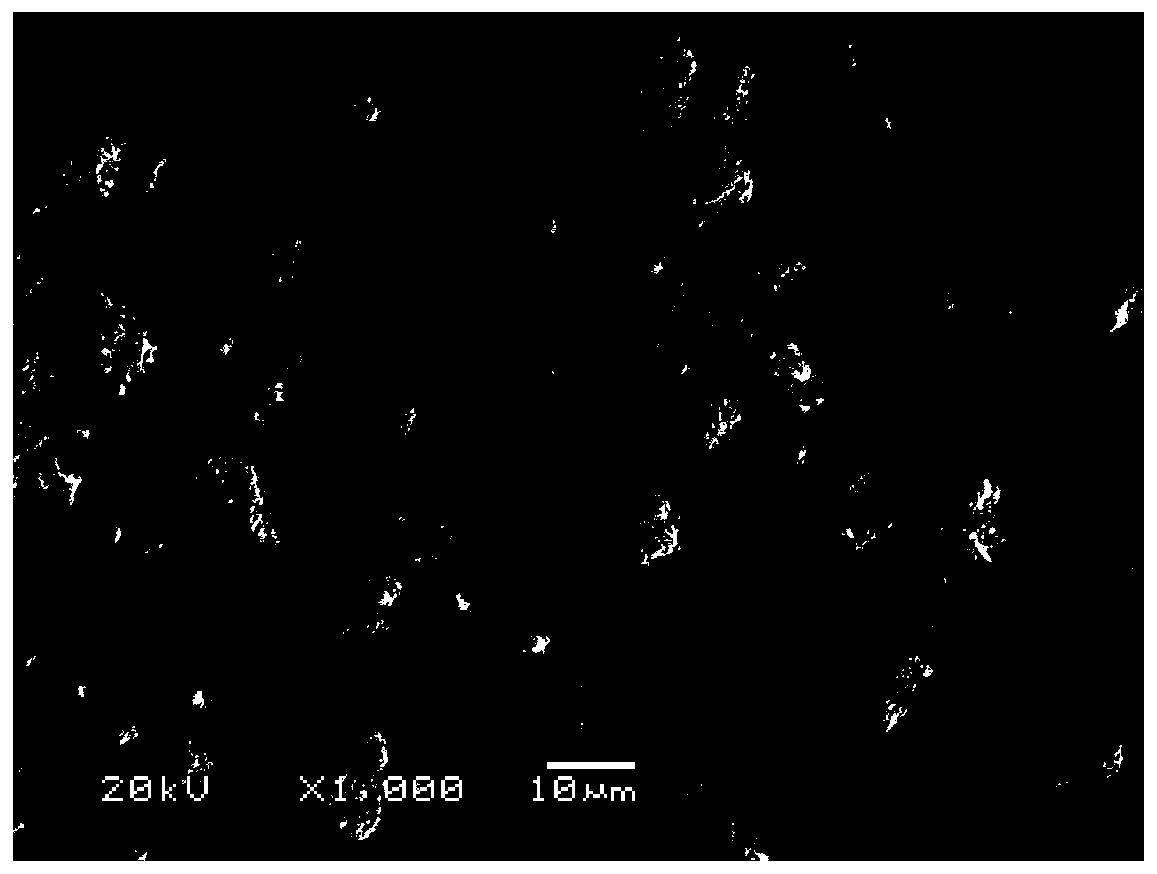

[0045] (1.1) Weigh 110gAl 2 (SO 4 ) 3 18H 2 O, dissolved in 200ml of deionized water, stirred rapidly to make it completely dissolved and placed on a magnetic stirrer.

[0046] (1.2) Add 100g / L NaOH solution dropwise to the aluminum sulfate solution at a constant speed, and measure its pH value in real time until the pH value of the solution reaches 6.2, stop the dropwise addition, and continue stirring for 12h.

[0047] (1.3) After stirring, vacuum filter, wash with deionized water until the pH value of the filtrate is the same as that of deionized water, and then filter again.

[0048] (1.4) The obtained filter cake was placed in a constant temperature drying oven, and dried at a constant temperature of 100°C. After it was completely dehydrated, it was ground and passed through a 160-mesh sieve to obtain an aluminum hydroxide adsorbent.

[0049] (2) Get 50ml lepidolite ore neutral leach solution, record its F - The concentration is 2.6×10 -3 mol / L, adjust the pH value ...

Embodiment 2

[0053] (1) Preparation of aluminum-containing adsorbent

[0054] (1.1) Weigh 110gAl 2 (SO 4 ) 3 18H 2 O, dissolved in 200ml of deionized water, stirred rapidly to make it completely dissolved and placed on a magnetic stirrer.

[0055] (1.2) Add 100g / L NaOH solution dropwise to the aluminum sulfate solution at a constant speed, and measure its pH value in real time until the pH value of the solution reaches 5.8, stop the dropwise addition, and continue stirring for 12 hours.

[0056] (1.3) After stirring, vacuum filter, wash with deionized water until the pH value of the filtrate is the same as that of deionized water, and then filter again.

[0057] (1.4) The obtained filter cake was placed in a constant temperature drying oven, and dried at a constant temperature of 100°C. After it was completely dehydrated, it was ground and passed through a 160-mesh sieve to obtain an aluminum hydroxide adsorbent.

[0058] (2) Get 50ml lepidolite ore neutral leach solution, record its ...

Embodiment 3

[0062] (1) Preparation of aluminum-containing adsorbent

[0063] (1.1) Weigh 110gAl 2 (SO 4 ) 3 18H 2 O, dissolved in 200ml of deionized water, stirred rapidly to make it completely dissolved and placed on a magnetic stirrer.

[0064] (1.2) Add 100g / L NaOH solution dropwise to the aluminum sulfate solution at a constant speed, and measure its pH value in real time until the pH value of the solution reaches 5.9, stop the dropwise addition, and continue stirring for 12h.

[0065] (1.3) After stirring, vacuum filter, wash with deionized water until the pH value of the filtrate is the same as that of deionized water, and then filter again.

[0066] (1.4) The obtained filter cake was placed in a constant temperature drying oven, and dried at a constant temperature of 100°C. After it was completely dehydrated, it was ground and passed through a 160-mesh sieve to obtain an aluminum hydroxide adsorbent.

[0067] (2) Get 50ml lepidolite ore neutral leach solution, record its F - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com