Blast cleaning process, and method and apparatus for producing solid carbon dioxide used in the same

A technology of solid carbon dioxide and liquid carbon dioxide, applied in cleaning methods and utensils, manufacturing tools, chemical instruments and methods, etc., can solve the problems of dry ice hardness reduction, mixed impurities, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

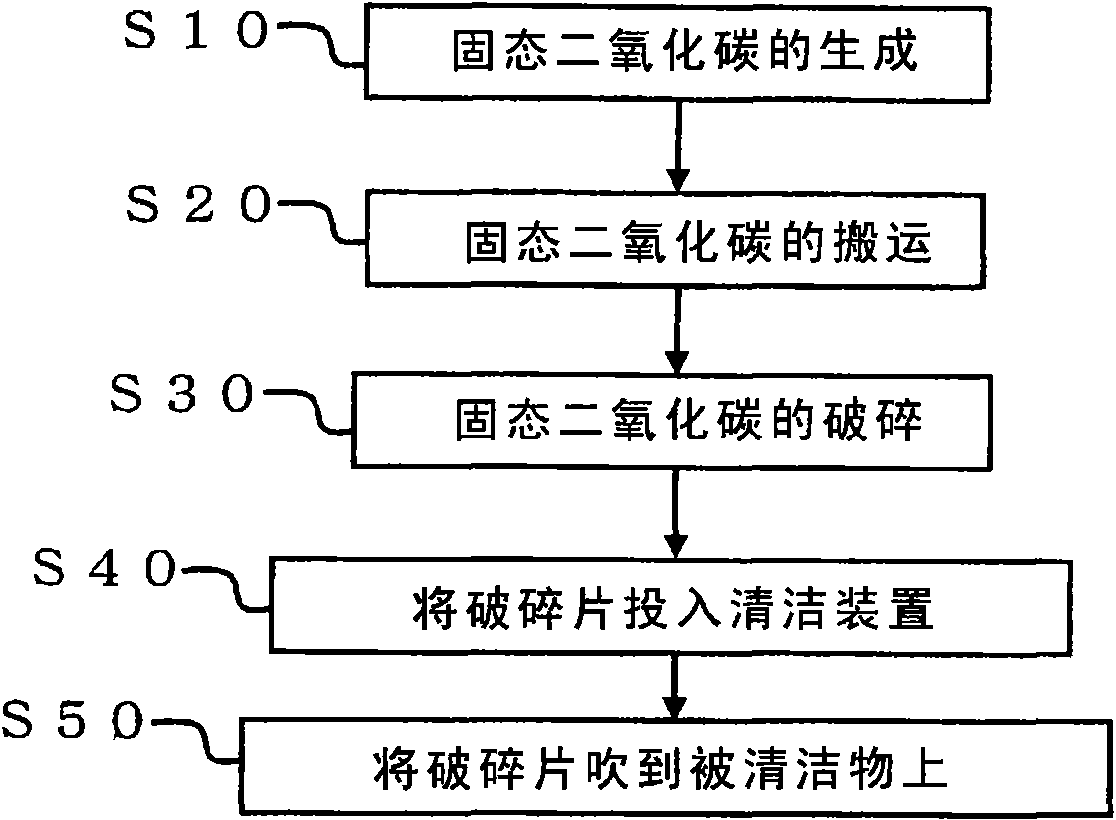

[0081] use figure 1 To illustrate an embodiment of the spray washing method.

[0082] figure 1 It is a process chart of the spray washing method of the embodiment of the present invention.

[0083] The spray washing method of this embodiment is characterized in that the broken pieces of solid carbon dioxide are used for the emission material, such as figure 1 As shown, the method includes: a process of generating plate-shaped solid carbon dioxide using a broken piece as a launch material (step S10), a process of transporting the generated plate-shaped solid carbon dioxide to a work site, etc. (step S20), at a work site, etc. The process of crushing the plate-shaped solid carbon dioxide (step S30), the process of throwing the crushed pieces into a cleaning device (spraying device) (step S40), and blowing them onto the object to be cleaned (step S50).

[0084] First, in step S10, liquid carbon dioxide is previously cooled in a factory or the like in a state where a pressure higher than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com