Lead storage battery

A lead-acid battery and battery technology, applied in secondary battery manufacturing, battery pack components, circuits, etc., can solve the problems of lead-acid battery prices rising and productivity decline, and achieve the effect of reducing the number of parts and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

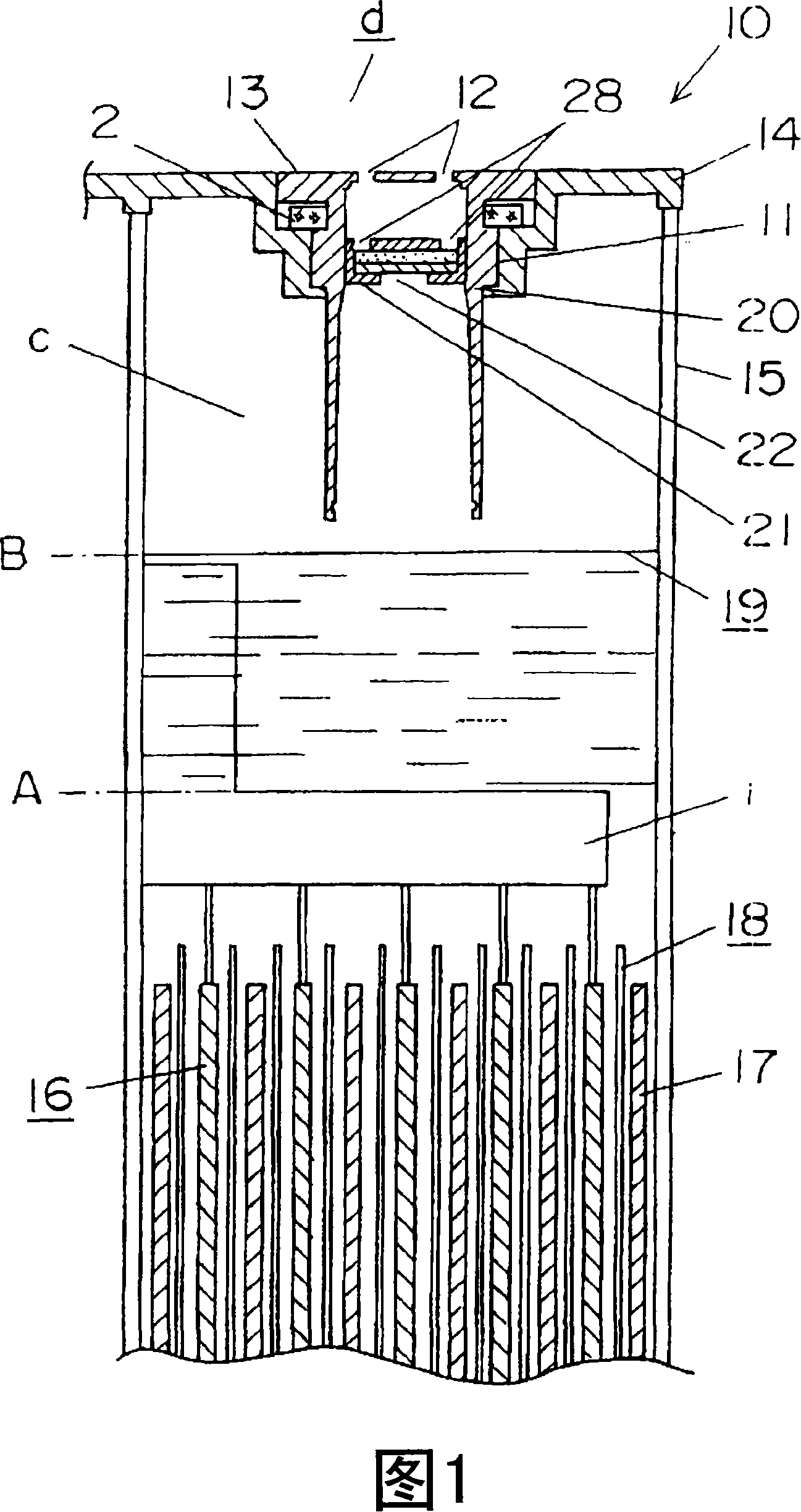

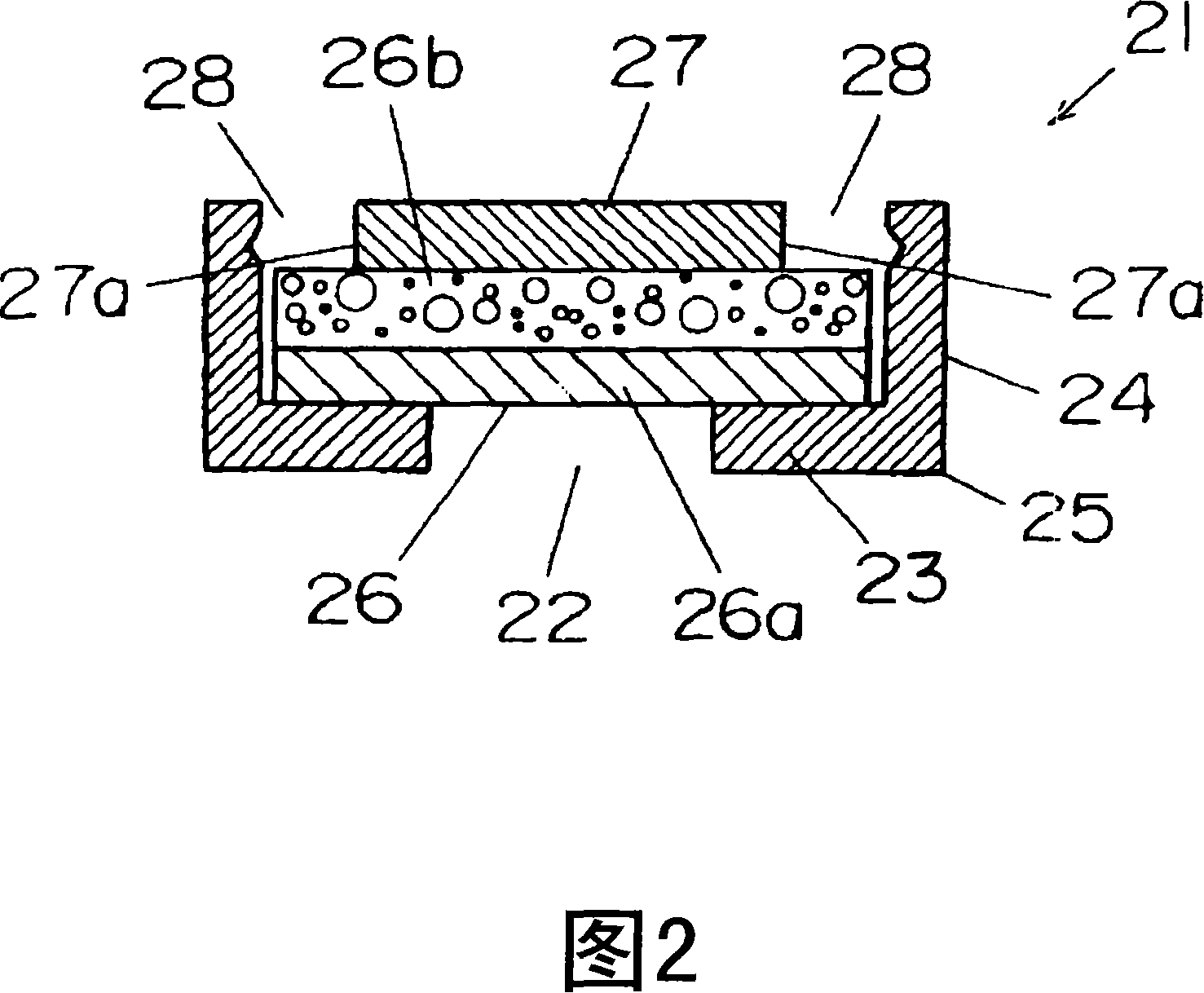

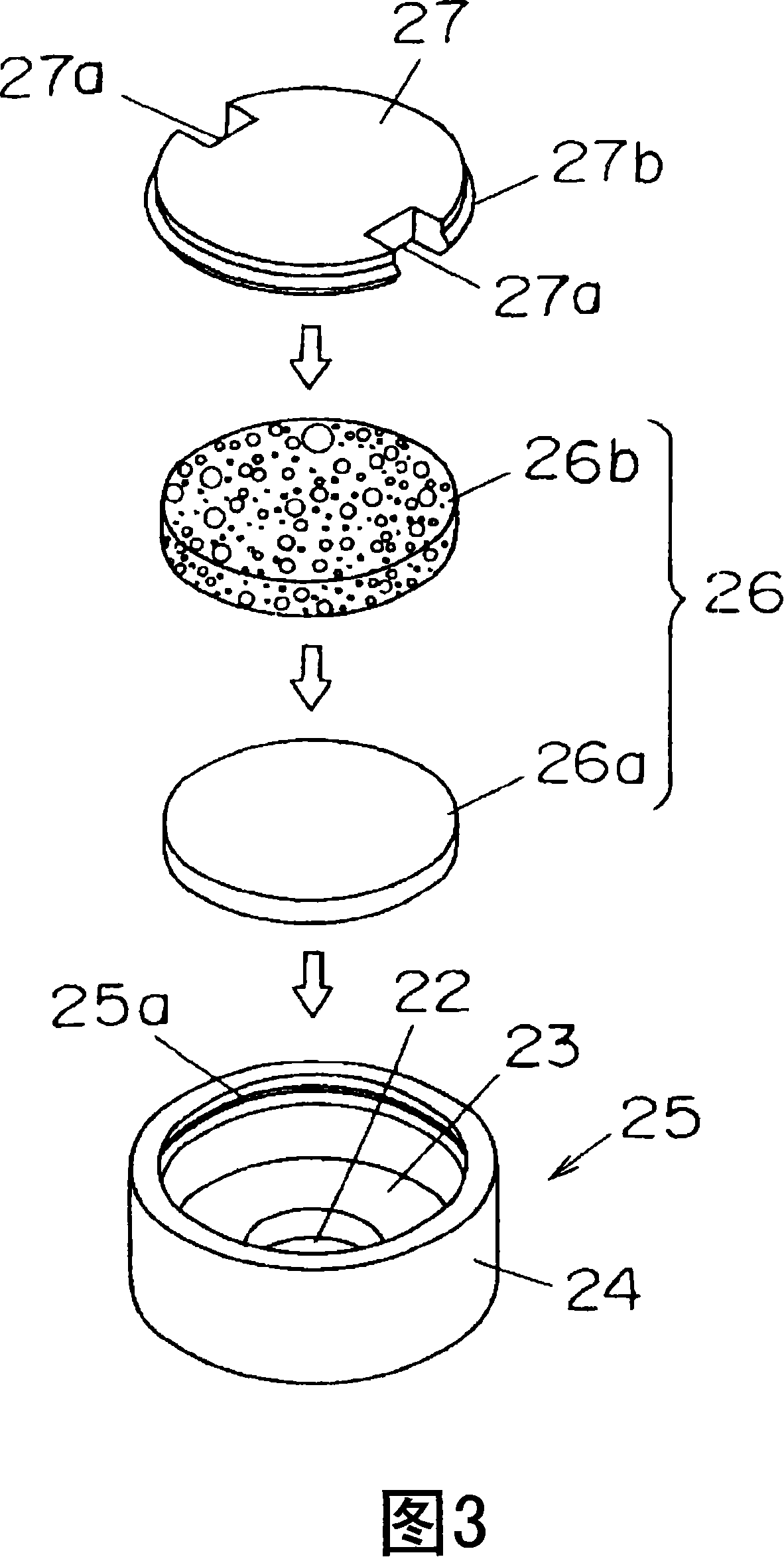

[0066] First, the first embodiment will be described. FIG. 1 is a diagram showing a cross section of a main part of a liquid lead-acid storage battery according to a first embodiment.

[0067] In the lead acid storage battery 10 of the first embodiment, the liquid port plug 13 provided with the vent hole 12 for discharging the gas inside the battery to the outside of the battery is attached to the liquid port 11 provided in the battery case. In addition, in the example shown in FIG. 1, the example in which the liquid port 11 is provided in the cover 14 which is a battery case is shown.

[0068] The positive electrode plate 16, the negative electrode plate 17, and the separator 18 accommodated in the electric tank 15 of the lead acid battery 10 are configured such that the entire surface of the electrode plate surface of the positive electrode plate 16 and the electrode plate surface of the negative electrode plate 17 are immersed in Electrolyte 19. In this lead-acid battery ...

no. 2 Embodiment approach

[0088] FIG. 4 is a diagram showing a cross section of a main part of a lead acid battery 50 according to the second embodiment. In addition, the same reference numerals are assigned to the same structures as those in the above-mentioned embodiment, and only differences will be mainly described in detail. In the lead acid battery 50 of the second embodiment, the air-permeable porous filter 51 is arranged on the passage between the vent hole 12 and the control valve part 21 in the main body cylinder 20 of the liquid port plug 13 .

[0089] The porous filter 51 can prevent foreign matter such as dust and sand particles from falling from the outside of the battery to the control valve unit 21, and can stabilize the valve opening operation of the control valve. In addition, when the flame or electric spark generated outside the battery ignites the oxygen and hydrogen existing around the exhaust hole 22, the combustion flame may reach the control valve part 21 and damage the control...

no. 3 Embodiment approach

[0094] FIG. 5 is a diagram showing a cross section of a lead storage battery 70 according to the third embodiment. In addition, the same reference numerals are assigned to the same structures as those in the above-mentioned embodiment, and only differences will be mainly described in detail. In the lead storage battery 70 of the third embodiment, the anti-foaming plate 71 facing the exhaust hole 22 is arranged in the main body cylinder 20 , which is characterized in that.

[0095] In the lead-acid storage battery 70 of the third embodiment, unlike the valve-controlled lead-acid storage battery in which there is almost no electrolytic solution released from the electrode plate group, since there is an electrolytic solution that immerses the entire surface of the electrode plate, vibrations applied to the battery may The liquid surface is shaken to make the electrolytic solution adhere to the control valve unit 21 . In such a case, the valve opening operation of the control val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com