Resin molding apparatus

A resin molding and metal mold technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of high energy consumption, longer molding cycle, longer cooling resin time, etc., to improve durability and shorten molding. effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In this case, an injection molding machine as a molding machine and a mold device as a resin molding device will be described.

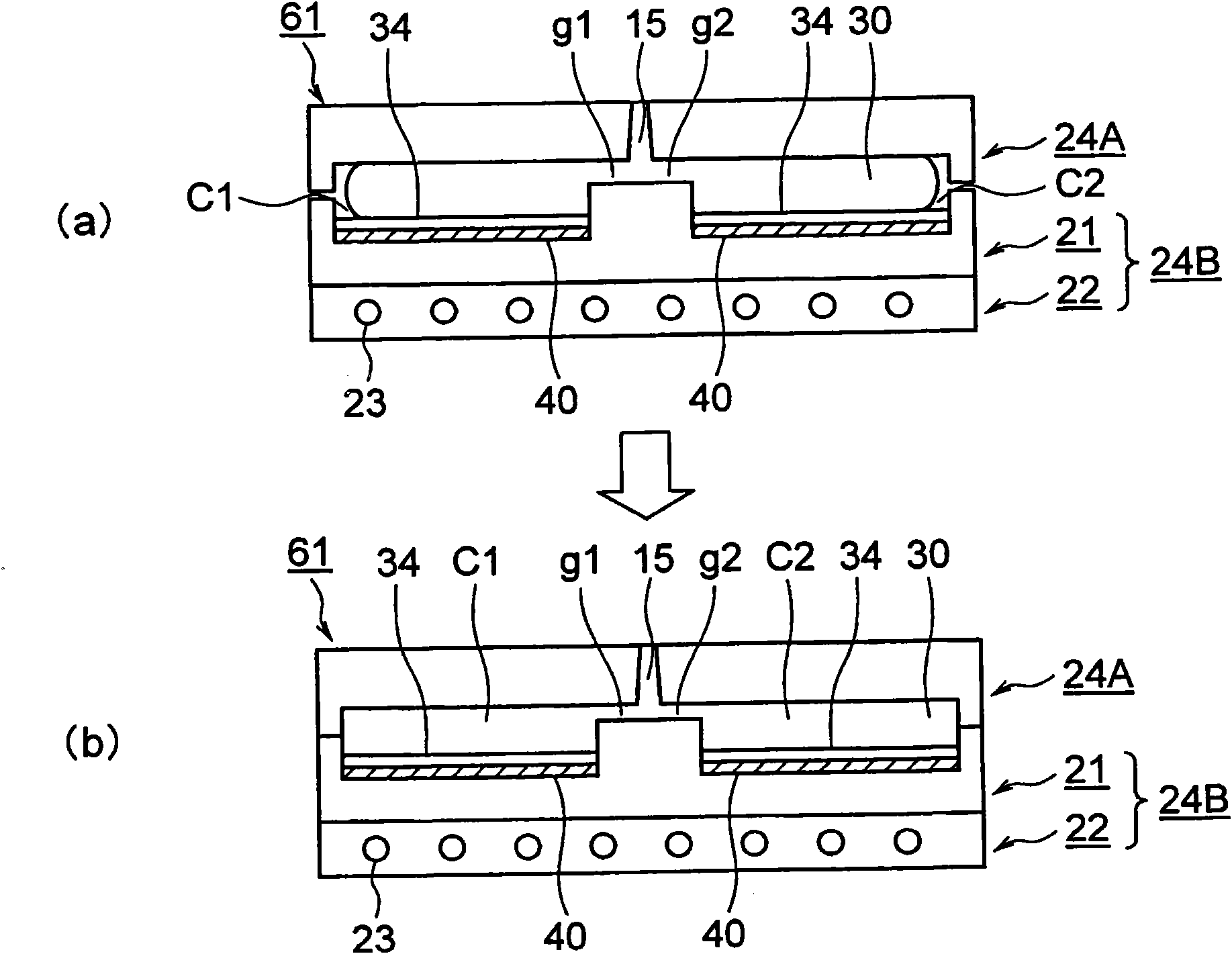

[0045] figure 2 It is a sectional view showing the resin molding method according to the first embodiment of the present invention. in addition, figure 2 (a) is a figure which shows the state which filled the cavity space C1, C2 with the resin 30 which is a molding material, figure 2 (b) is a figure which shows the state which clamped the mold.

[0046]In the figure, 61 is a metal mold device as a resin molding device for molding a molded product such as a light guide plate, 24A is a fixed metal mold as a first mold part and as a first metal mold, and 24B is a metal mold corresponding to the first metal mold. The fixed die 24A is a movable die which is a second die member and is arranged to move forward and backward freely. Fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com