Toner Metering Conveyor System

A conveying system and toner technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems affecting the manufacturing quality of toner fibers, numerical errors, etc., to improve applicability, accuracy, and dyeing. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

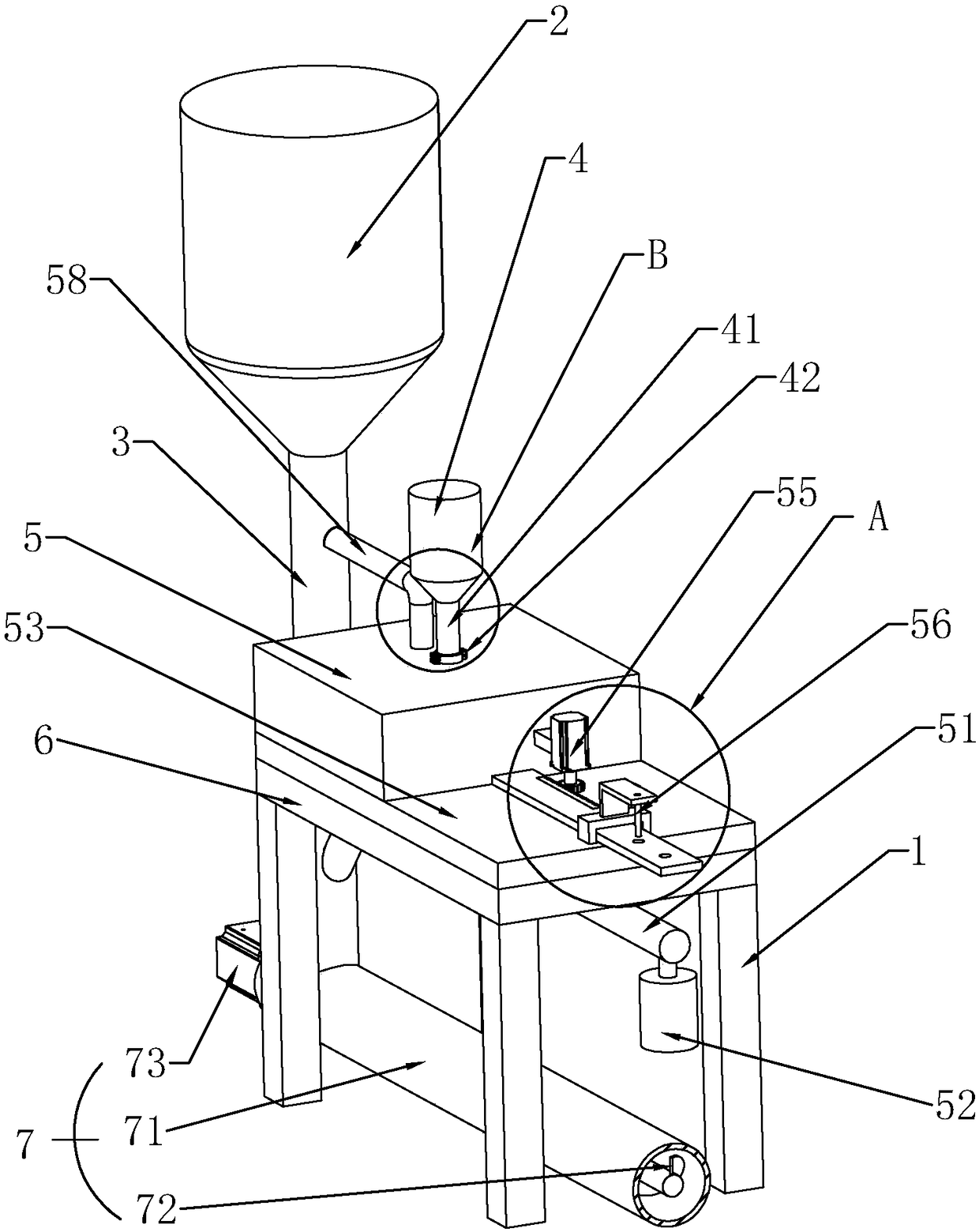

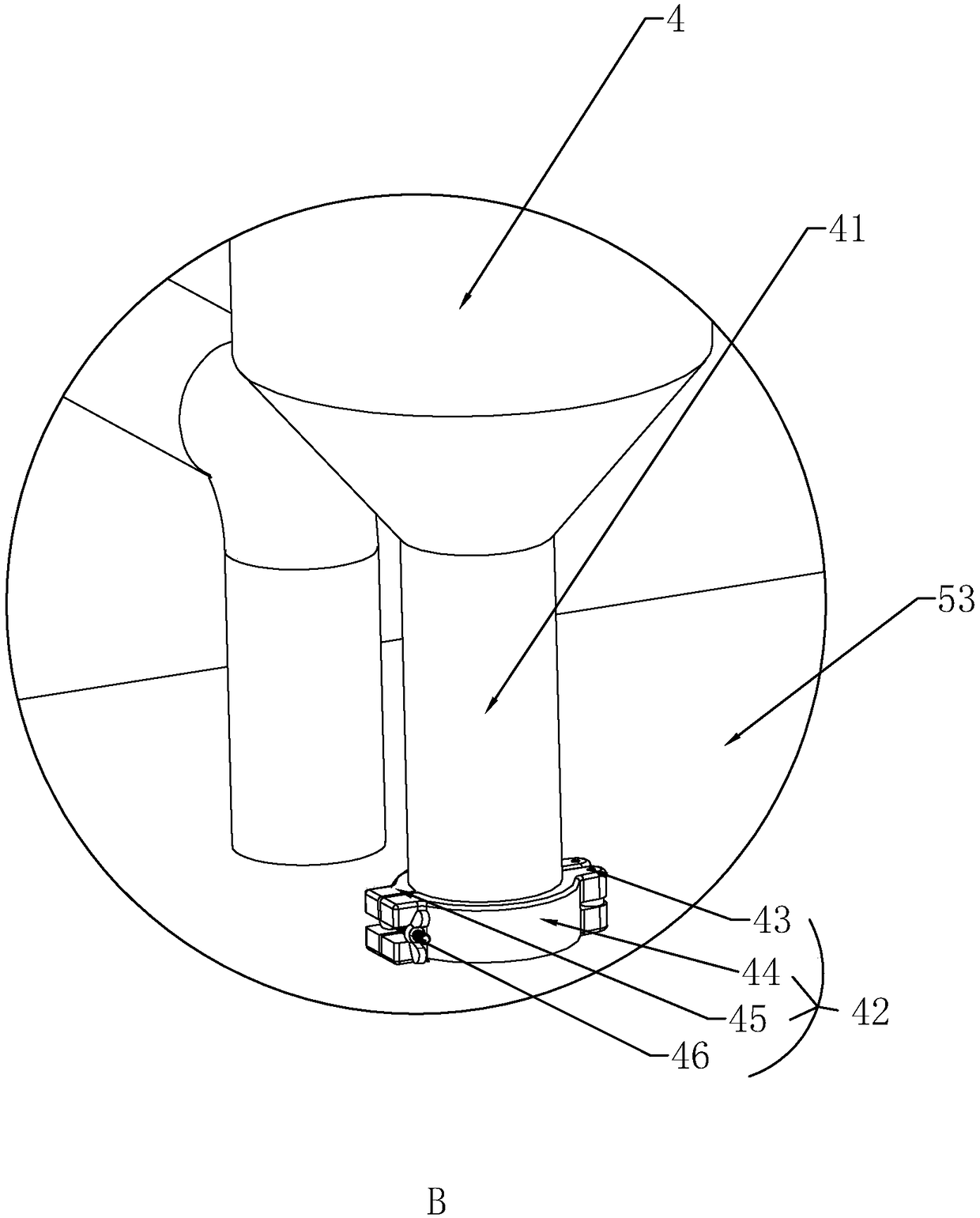

[0039] Embodiment 1: a kind of toner metering delivery system, such as figure 1 As shown, it includes a drying tower 2 arranged on a frame 1 for storing polylactic acid dry slices, a slicing pipeline 3 connected to the drying tower 2 for transporting polylactic acid dry slices, a silo 4 for storing toner, It is used to transport the toner in the silo 4 to the conveying device 5 in the slicing pipeline, and the mixing and melting device 7 connected to the slicing pipeline 3 for conveying the dry chips of polylactic acid and the toner mixed with each other; the silo 4 also It can measure powdery materials such as toner, nano-scale metal powder, nano-scale bamboo toner, titanium dioxide, etc.

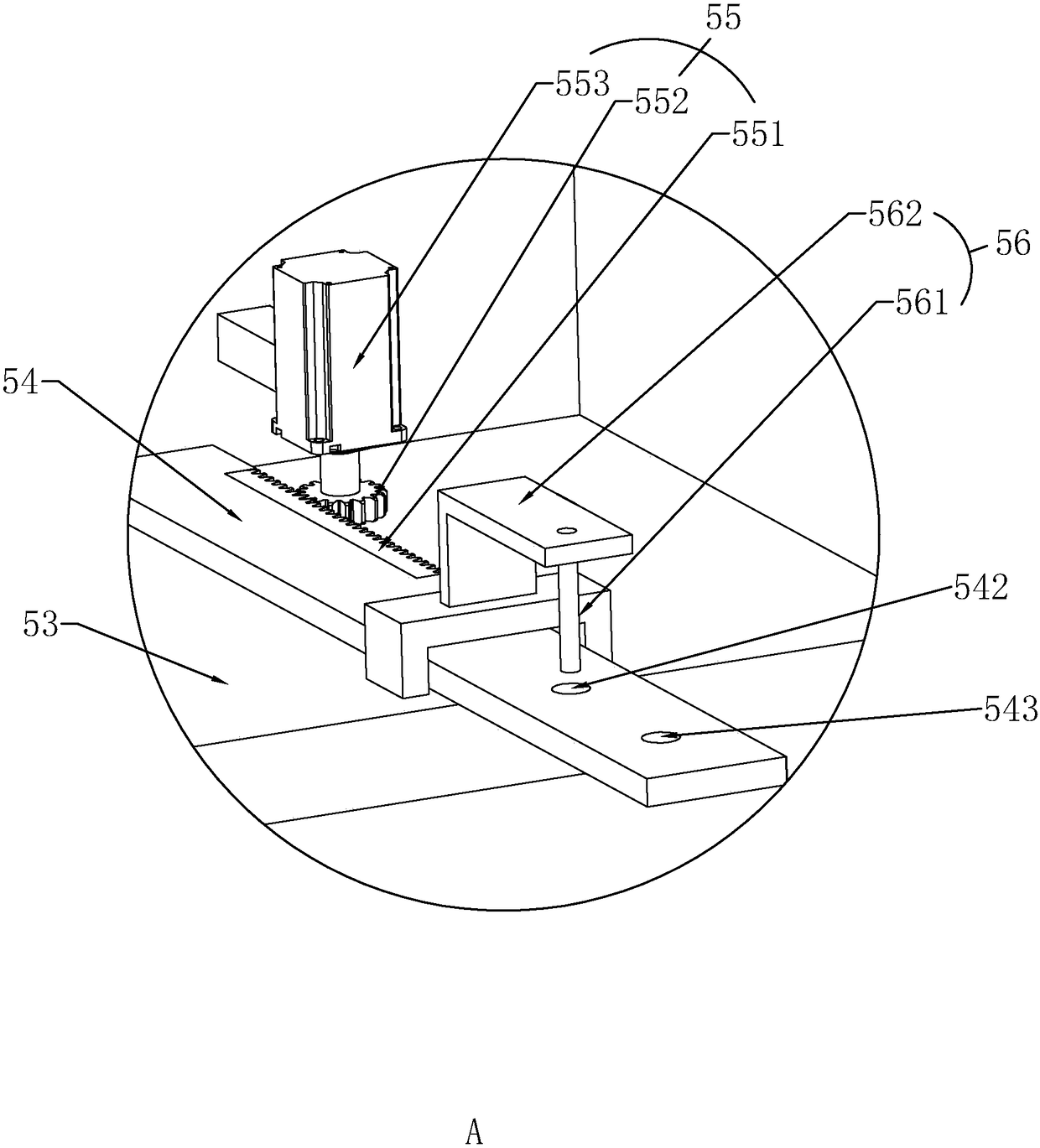

[0040] Such as Figure 4 As shown, wherein, the conveying device 5 includes an airflow passage 51 connected to the slice pipeline 3 at one end, a solenoid valve 52 arranged at the other end of the airflow passage 51 for controlling the delivery of compressed air flow in the airflow passag...

Embodiment 2

[0052] Embodiment 2: a toner metering delivery system, the difference from embodiment 1 is that, as Figure 7 As shown, the drive assembly 55 includes a threaded screw 554 connected to the flashboard 54 and a rotating motor 555 that drives the screw 554 to rotate forward and reverse. The rotating motor 555 is connected to the base plate 53; , so that the screw rod 554 is on the board 54 and is connected with the screw rod 554 of the board 54 to drive the board 54 to slide on the bottom plate 53, and the rotating motor 555 cooperates with the induction component 56 at the same time, so as to adjust the board 54 to be on the bottom board 53 Reciprocating motion effect towards the toner channel 57 direction.

Embodiment 3

[0053] Embodiment 3: a kind of toner metering conveying system, differs from embodiment 1 in that, as Figure 8 As shown, the drive assembly 55 is a hydraulic cylinder 556, the piston of the hydraulic cylinder 556 is fixedly connected to the inserting plate 54, and the sensing assembly 56 controls the reciprocating movement of the piston at intervals, thereby controlling the reciprocating movement of the inserting plate 54 on the base 6 to achieve continuous quantitative The purpose of conveying toner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com