Quartz sand conveying device and method

A technology of conveying device and quartz sand, which is applied in the direction of transportation and packaging, conveyor objects, loading/unloading, etc. It can solve the problems of unstable flow of quartz sand, difficulty in loading raw materials, and pollution of quartz sand to ensure stability and product quality. quality, achieve centralized management and flexible movement and deployment, and reduce security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

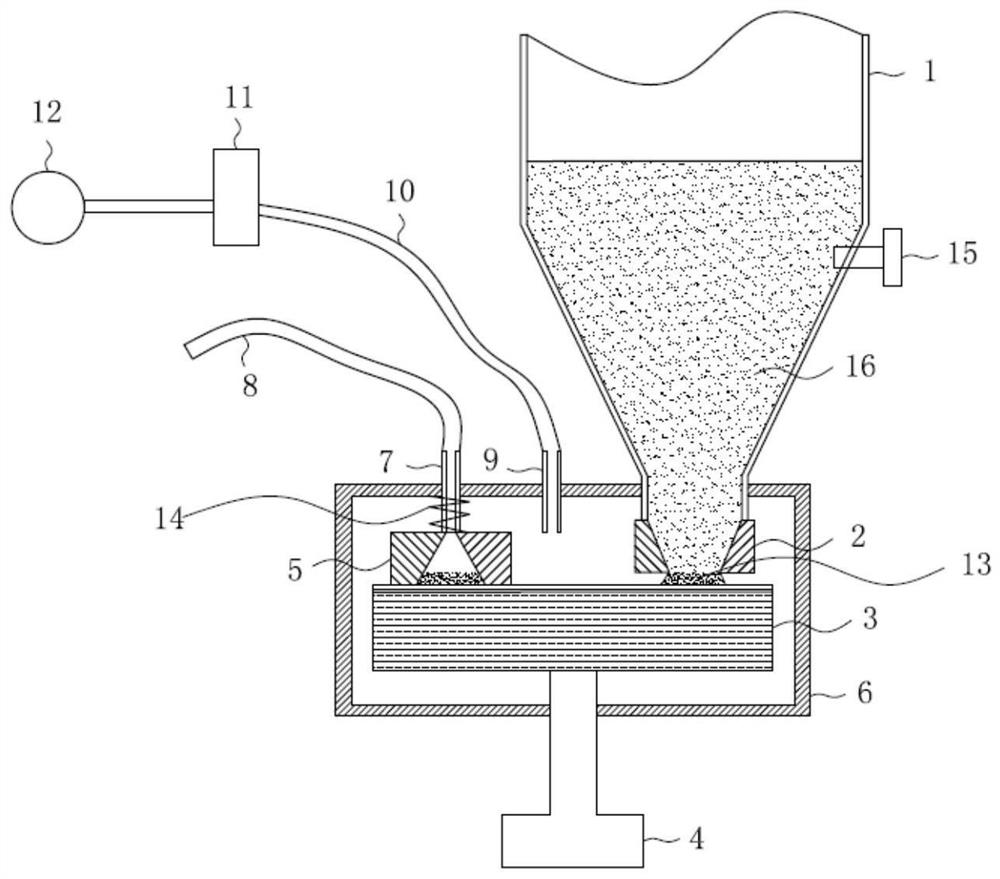

[0073] A quartz sand feeding device proposed by an embodiment of the present invention consists of a storage bin 1, a feeding block 2, a transfer plate 3, a rotary drive system 4, a blowing block 5, a sealing bin 6, a material output port 7, a material Consists of a delivery pipeline 8, a gas input port 9, a gas input pipeline 10, a flow meter 11, a pressure controller 12, and a position sensor 15. The blanking block 2, the transfer plate 3, and the blowing block 5 are located in the sealed bin 6, the storage bin 1, the rotary drive system 4, the material output port 7, the gas input port 9 and the sealed bin 6 are sealed connections, and the sealed bin 6 The gas is not connected to the outside world. Driven by the rotary drive system 4 , the transmission disc 3 can rotate along its own rotating shaft. The blanking block 2 is fixed above the conveying tray 3, the outlet of the blanking block 2 maintains a fixed gap with the conveying tray 3, and the blanking block 2 is connec...

Embodiment 2

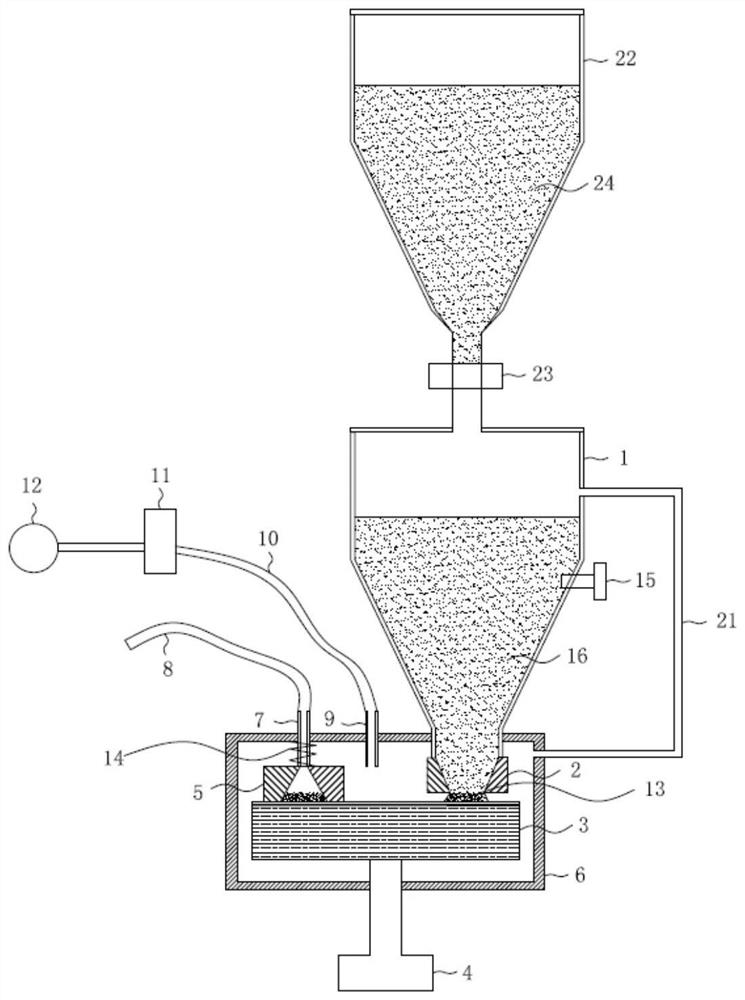

[0078] A quartz sand feeding device proposed by an embodiment of the present invention consists of a storage bin 1, a feeding block 2, a transfer plate 3, a rotary drive system 4, a blowing block 5, a sealing bin 6, a material output port 7, a material Consists of a delivery pipeline 8, a gas input port 9, a gas input pipeline 10, a flow meter 11, a pressure controller 12, a pressurizing device 14, and a position sensor 15. The blanking block 2, the transfer plate 3, and the blowing block 5 are located in the sealed bin. The storage bin 1, the rotary drive system 4, the material output port 7, the gas input port 9 and the sealed bin 6 are hermetically connected, and the gas in the sealed bin 6 Not connected with the outside world. Driven by the rotary drive system 4 , the transmission disc 3 can rotate along its own rotating shaft. The blanking block 2 is fixed above the conveying tray 3, the outlet of the blanking block 2 maintains a fixed gap with the conveying tray 3, and ...

Embodiment 3

[0084] A quartz sand feeding device proposed by an embodiment of the present invention consists of a storage bin 1, a feeding block 2, a transfer plate 3, a rotary drive system 4, a blowing block 5, a sealing bin 6, a material output port 7, a material Consists of a delivery pipeline 8, a gas input port 9, a gas input pipeline 10, a flow meter 11, a pressure controller 12, and a position sensor 15. The blanking block 2, the transfer plate 3, and the blowing block 5 are located in the sealed bin. The storage bin 1, the rotary drive system 4, the material output port 7, the gas input port 9 and the sealed bin 6 are hermetically connected, and the gas in the sealed bin 6 Not connected with the outside world. Driven by the rotary drive system 4 , the transmission disc 3 can rotate along its own rotating shaft. The blanking block 2 is fixed above the conveying tray 3, the outlet of the blanking block 2 maintains a fixed gap with the conveying tray 3, and the blanking block 2 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com