Water-resistant transparent paper and its preparation method and application

A technology of transparent paper and hydrophobic groups, which is applied in papermaking, textile and papermaking, pulping with halogen compounds, etc., can solve the problems of lack of water resistance, lack of strength, and increased processes, so as to achieve water resistance and transparency. The effect of durability, wide use scene, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing the aforementioned cellulose water-resistant transparent paper, which includes the following steps: immersing the cellulose transparent paper in an alkaline solution for treatment, cleaning after the treatment is completed, and then drying.

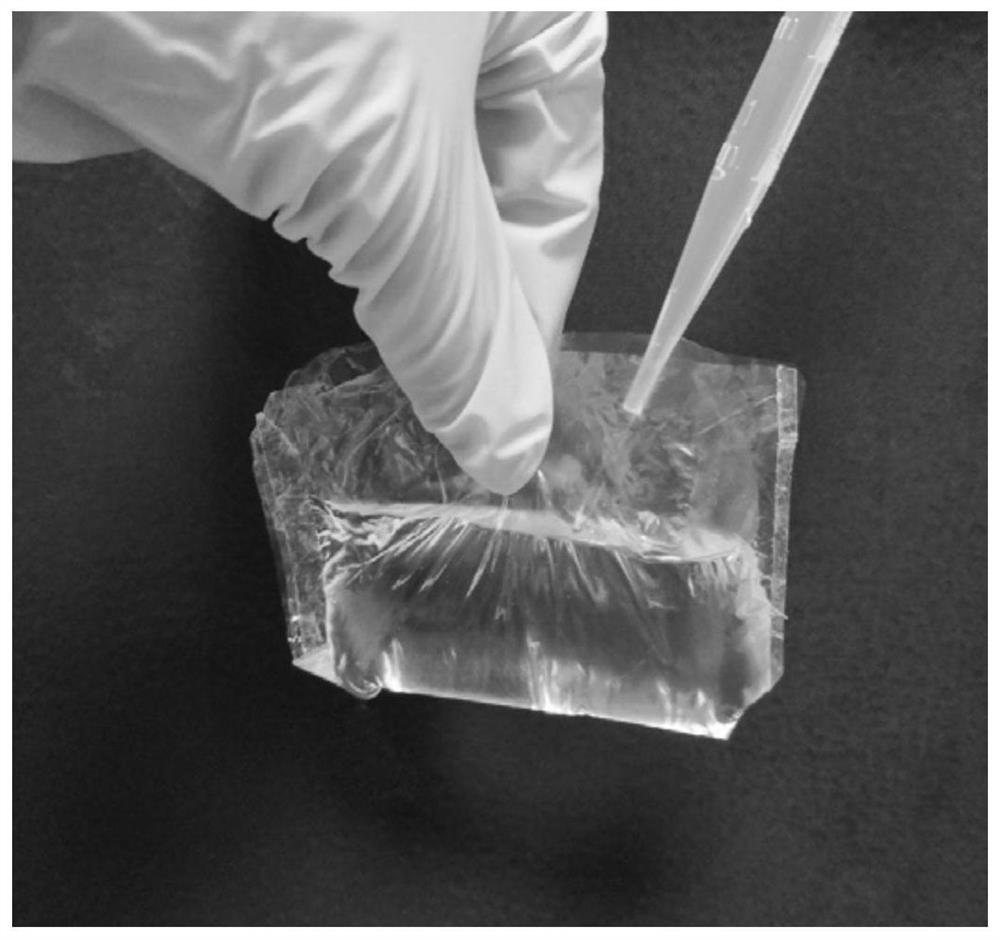

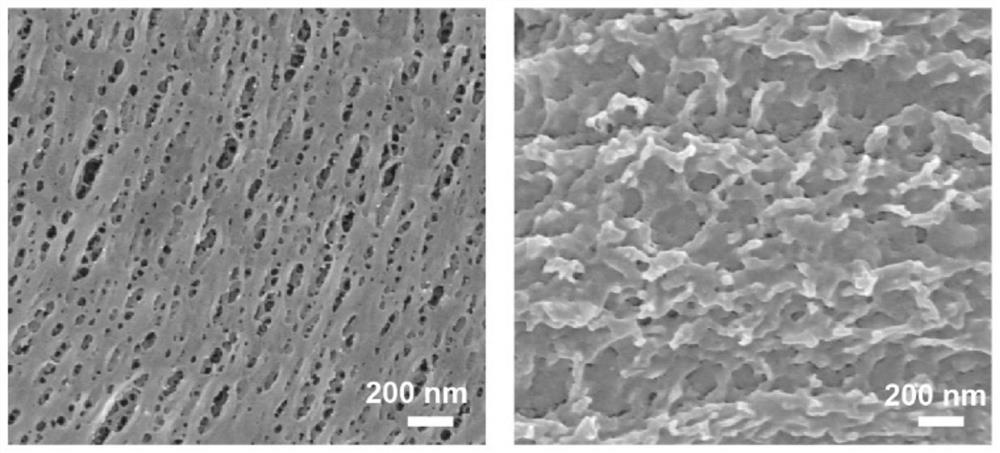

[0029]The natural cellulose crystal form in nature is cellulose type I, and the molecular chains of cellulose type I are arranged in parallel. After the cellulose paper is immersed in an alkaline solution, it is converted into cellulose type II after being treated with an alkaline solution. The molecular chains of the cellulose type II are anti-parallel. From the appearance, the cellulose type II is helical. Specifically, when the cellulose paper is immersed in the lye solution, it first swells, so that the alkali penetrates into the crystal plane of the crystallization zone and forms a hydrated crystalline compound with the cellulose molecules. Part of it forms an amorphou...

Embodiment 1

[0045] The basswood sawdust was mixed with a sodium hypochlorite solution with a concentration of 15%, the mass ratio of sawdust and sodium hypochlorite was 1:10, and the temperature was 50 ° C, and the reaction was carried out for 10 minutes. After the reaction, washed with water three times to remove the residual sodium hypochlorite. The slurry was filtered with a suction filtration device to remove a large amount of water, and then the product was placed in a press, and the pressure was maintained at 0.1 MPa for 0.1 hour to obtain transparent paper;

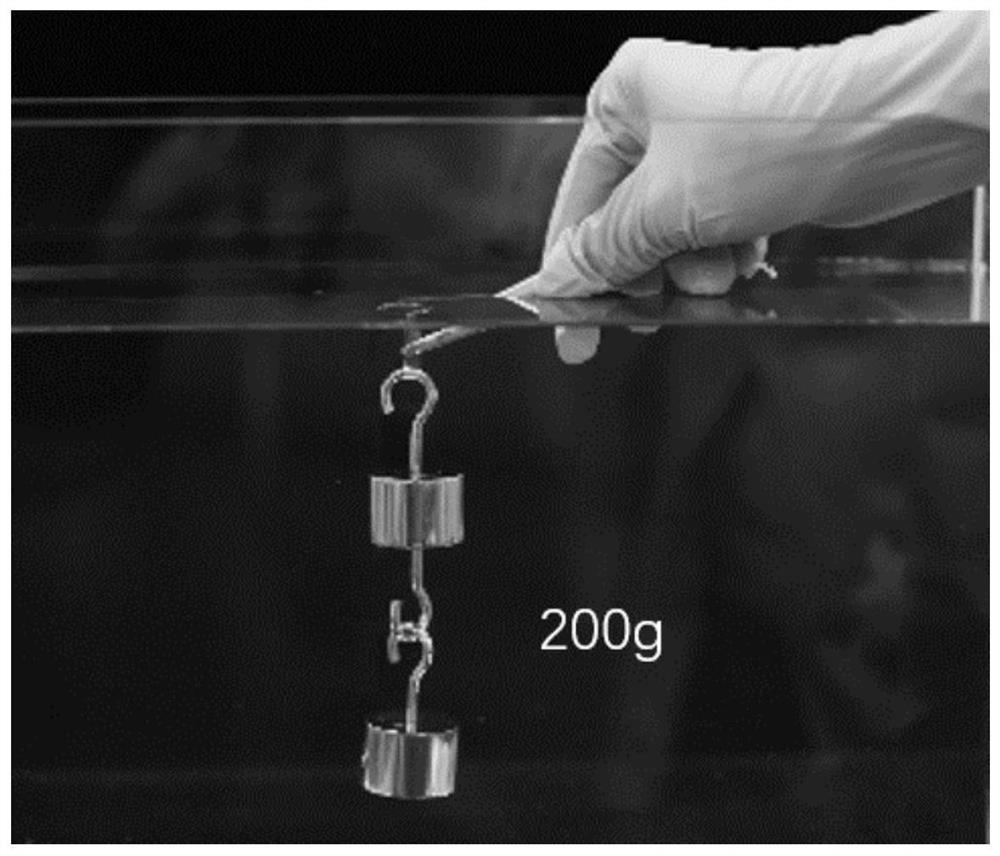

[0046] The transparent paper was placed in an aqueous sodium hydroxide solution with a concentration of 20% by mass and a temperature of 25° C. for 5 minutes, and then washed for 5 minutes to obtain a water-resistant transparent paper material. In the water-resistant transparent paper, the fiber diameter is about 600 nm, the paper thickness is 20 μm, the transparency is 90%, and the strength of the paper in water is about 15.1 ...

Embodiment 2

[0048] The basswood sawdust was mixed with a sodium hypochlorite solution with a concentration of 15%, the mass ratio of sawdust and sodium hypochlorite was 1:10, and the temperature was 50 ° C, and the reaction was carried out for 10 minutes. After the reaction, washed with water three times to remove the residual sodium hypochlorite. The slurry was filtered with a suction filtration device to remove a large amount of water, and then the product was placed in a press, and the pressure was maintained at 0.1 MPa for 0.1 hour to obtain transparent paper;

[0049] The transparent paper was placed in an aqueous sodium hydroxide solution with a concentration of 17% by mass and a temperature of 25° C. for 5 minutes, and then washed for 5 minutes to obtain a water-resistant transparent paper material. The fiber diameter of the water-resistant transparent paper is about 800 nm, the thickness of the paper is 20 μm, the transparency is 88%, and the strength of the paper in water is about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com