Impregnation liquid and transparent paper sheets prepared from impregnation liquid as well as method for rapidly preparing transparent paper sheets

A technology for dipping liquid and paper, which is applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of complex preparation technology and procedures, unfavorable large-scale production, complex technological process, etc., and achieves easy preparation, easy industrial production, and operation technology. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation of transparent paper, the steps are as follows:

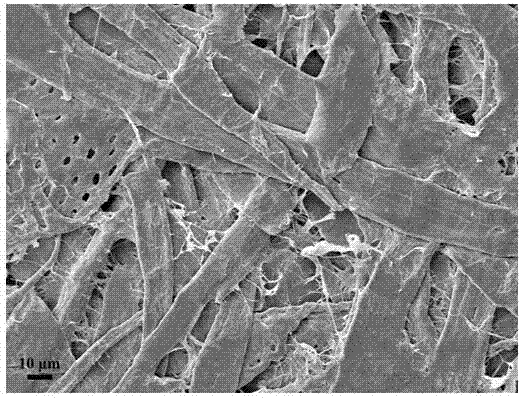

[0043] The basis paper adopts a basis weight of 25 g / m 2 Wrapping paper with a tightness of 0.5 g / cm 3 , the scanning electron microscope image of the base paper is shown in figure 1 shown by figure 1 It can be seen that the base paper fibers are intertwined with each other and have many pores.

[0044] Impregnation solution: 500 g of transparent agent, 1.5 g of surfactant, 2.5 g of water-resistant agent and 4 g of lubricant; the transparent agent is acrylic resin, the surfactant is fatty alcohol polyoxyethylene ether, and the water-resistant agent is urea-formaldehyde resin , the lubricant is calcium stearate; the solid content of the impregnating liquid is 10%.

[0045] making process:

[0046] The base paper was soaked in the soaking solution for 10 s and the soaking amount was 20%, and then it was taken out, and then the soaked paper was closely attached between two film materials, the film...

Embodiment 2

[0051] A kind of preparation of transparent paper, the steps are as follows:

[0052] Base paper is 40 g / m 2 Tracing paper, 0.9 g / cm tight 3 .

[0053] Impregnation solution: 500 g of transparent agent, 2.5 g of surfactant, 3.5 g of water-resistant agent and 5 g of lubricant; the transparent agent is epoxy resin, the surfactant is fatty acid glyceride, and the water-resistant agent is ammonium zirconium carbonate. The lubricant is potassium oleate; the solid content of the impregnating liquid is 25%.

[0054] making process:

[0055] The base paper was soaked in the soaking solution for 5 s, and the soaking volume was 60%, and then it was taken out, and then the soaked paper was tightly attached between two sheets of film materials. The film material used was polyethylene film, and squeezed Squeeze out the excess impregnating liquid through the pressing device, and the extrusion device used is a hydraulic press;

[0056] Then the impregnated paper was separated from the f...

Embodiment 3

[0059] A kind of preparation of transparent paper, the steps are as follows:

[0060] Base paper is 65 g / m 2 Writing paper, 1.3 g / cm compact 3 .

[0061] Impregnation solution: 500 g of transparent agent, 4 g of surfactant, 4 g of water-resistant agent and 6 g of lubricant; the transparent agent is urea-formaldehyde resin, the surfactant is polysorbate, and the water-resistant agent is melamine formaldehyde resin, lubricating The agent is polyethylene glycol; the solid content of the impregnating liquid is 40%.

[0062] making process:

[0063] Put the base paper in the dipping solution for 20 s, the dipping amount is 80%, take it out, and then stick the soaked paper between two film materials, the film material used is BOPP, use extrusion device Squeeze out the excess impregnation liquid, and the extrusion device used is a hydraulic press;

[0064] Then the impregnated paper was separated from the film material, and the impregnated paper was dried and then calendered. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com