TCE bleaching technology for sulfate pulp of growing poplar by biological chemical method

A kraft pulp and biochemical technology, applied in pulp bleaching, digester, textile and papermaking, etc., can solve the problems of high energy consumption for refining, poor whiteness stability, easy yellowing, etc. The effect of saving beating energy consumption and less loss of beating whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

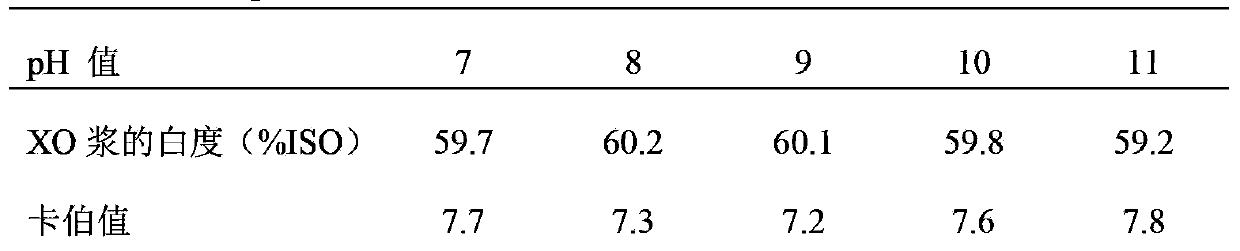

[0033] Example 1 Process optimization of xylanase treatment of fast-growing poplar kraft pulp

[0034] Xylanase is a specific catalytic protein, which has strict requirements on the environment, that is to say, each enzyme has its specific and most suitable environmental conditions. Xylanase has achieved obvious effects in chemical pulping and bleaching pretreatment. According to relevant literature, the factors affecting xylanase pretreatment mainly include enzyme dosage, temperature, pH value and time, etc. These factors have varying degrees of influence on the effect of oxygen delignification and subsequent bleaching. Among these influencing factors, temperature and pH value are related to the characteristics of xylanase itself, but have relatively little influence on the properties of slurry. In this experiment, by changing the experimental conditions, the most suitable process conditions for pretreatment of fast-growing poplar kraft pulp were discussed with different xyl...

Embodiment 2

[0103] The optimization of embodiment 2 bleaching process conditions

[0104] 2.1.1 Raw materials

[0105] The fast-growing poplar chips used in the experiment were mixed fast-growing poplar chips, which were obtained from Shandong Sun Paper Co., Ltd. The length of the wood chips is 15-25mm, the width is 10-20mm, and the thickness is 3-5mm. The qualified rate of the wood chips is over 90%.

[0106] Xylanase X 1 Provided by Novozymes, liquid, without cellulase activity; xylanase X 2 、X 3 All are provided by Shenzhen Lvweikang Biological Co., Ltd., all are white powdery solids, and none of them contain cellulase activity.

[0107] 2.1.2 Cooking experiment

[0108] Cook in a 15L electric heating rotary cooking pot to obtain the raw material of fast-growing poplar sulfate. The conditions for cooking are: the amount of alkali used is 20% (for absolute dry raw materials, Na 2 O meter), the degree of sulfidation is 24%, the liquid ratio is 1:4, the highest cooking temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com