Hot-pressing tympan paper and manufacturing method thereof

A backing plate and cardboard technology, applied in pulp beating/refining methods, special paper, chemical instruments and methods, etc., can solve the problems of poor high temperature resistance, high cost, uneven heat transfer, etc., and achieve cost reduction and utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

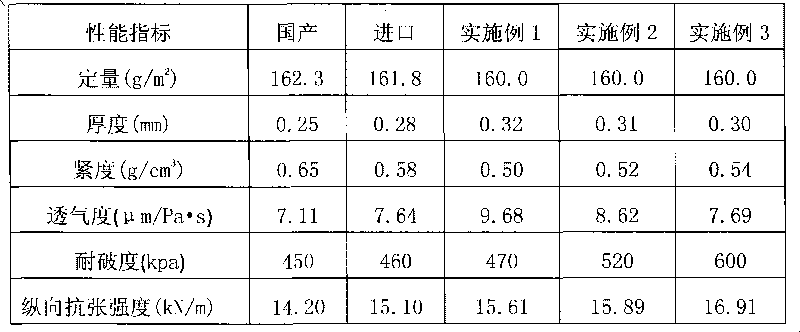

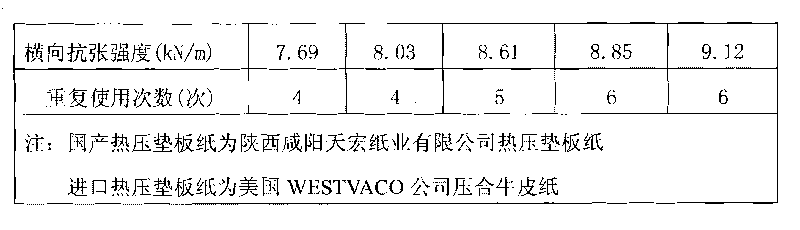

Examples

Embodiment 1

[0018] The weight of copying is 160g / m 2 The dry pulp weight of the natural color pulp used in the surface layer and the bottom layer accounted for 20% of the total dry pulp weight, and the dry pulp of the natural color pulp and fly ash fiber pulp mixed pulp used in the core layer The weight accounts for 60% of the total dry pulp weight, wherein the dry weight ratio of natural color pulp and fly ash fiber pulp is 25:75.

[0019] The papermaking technology of above-mentioned hot-pressed pad paper, concrete steps are:

[0020] In the first step, the natural color pulp board with a beating degree of 15°SR is beaten with free long fibers, the beating weight concentration is 3%, the beating degree is 20°SR, the average length of the fibers after beating is 4mm, and the diameter is 35-50μm. Then add a strengthening agent cationic polyacrylamide solution to the slurry, the cationic polyacrylamide content in the slurry is 0.005%, stir at room temperature for 20 minutes until the disp...

Embodiment 2

[0025] The weight of copying is 160g / m 2 The dry pulp weight of the natural color paste used in the surface layer and the bottom layer accounted for 25% of the total dry pulp weight; the dry pulp of the mixed pulp of the natural color paste and fly ash fiber pulp used in the core layer The weight accounts for 50% of the total dry pulp weight, wherein the dry weight ratio of natural color pulp and fly ash fiber pulp is 32:68.

[0026] The papermaking technology of above-mentioned hot-pressed pad paper, concrete steps are:

[0027] In the first step, the natural color pulp board with a beating degree of 15°SR is beaten with free long fibers, the beating weight concentration is 3%, the beating degree is 25°SR, and the average length of the fibers after beating is 3.5mm and the diameter is 35-50μm , and then add a reinforcing agent cationic polyacrylamide solution to the pulp, the cationic polyacrylamide content in the pulp is 0.005%, stir at room temperature for 20 minutes until...

Embodiment 3

[0032] The weight of copying is 160g / m 2 The dry pulp weight of the natural color paste used in the surface layer and the bottom layer accounted for 30% of the total dry pulp weight; the dry pulp of the natural color paste and fly ash fiber pulp mixed pulp used in the core layer The weight accounts for 40% of the total dry pulp weight, wherein the dry weight ratio of natural color pulp and fly ash fiber pulp is 40:60.

[0033] The papermaking technology of above-mentioned hot-pressed pad paper, concrete steps are:

[0034] In the first step, the natural color pulp board with a beating degree of 15°SR is beaten with free long fibers, the beating weight concentration is 3%, the beating degree is 30°SR, the average length of the fibers after beating is 3mm, and the diameter is 35-50μm. Then add a strengthening agent cationic polyacrylamide solution to the slurry, the cationic polyacrylamide content in the slurry is 0.005%, stir at room temperature for 20 minutes until the disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com