Multiple layer composite micropore filtration separation material and preparation method and use thereof

A technology for microporous filtration and separation of materials, applied in filtration separation, separation methods, semi-permeable membrane separation, etc., can solve the problems of small strength elongation at break, achieve uniform pore size distribution, improve pore uniformity, and good use. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

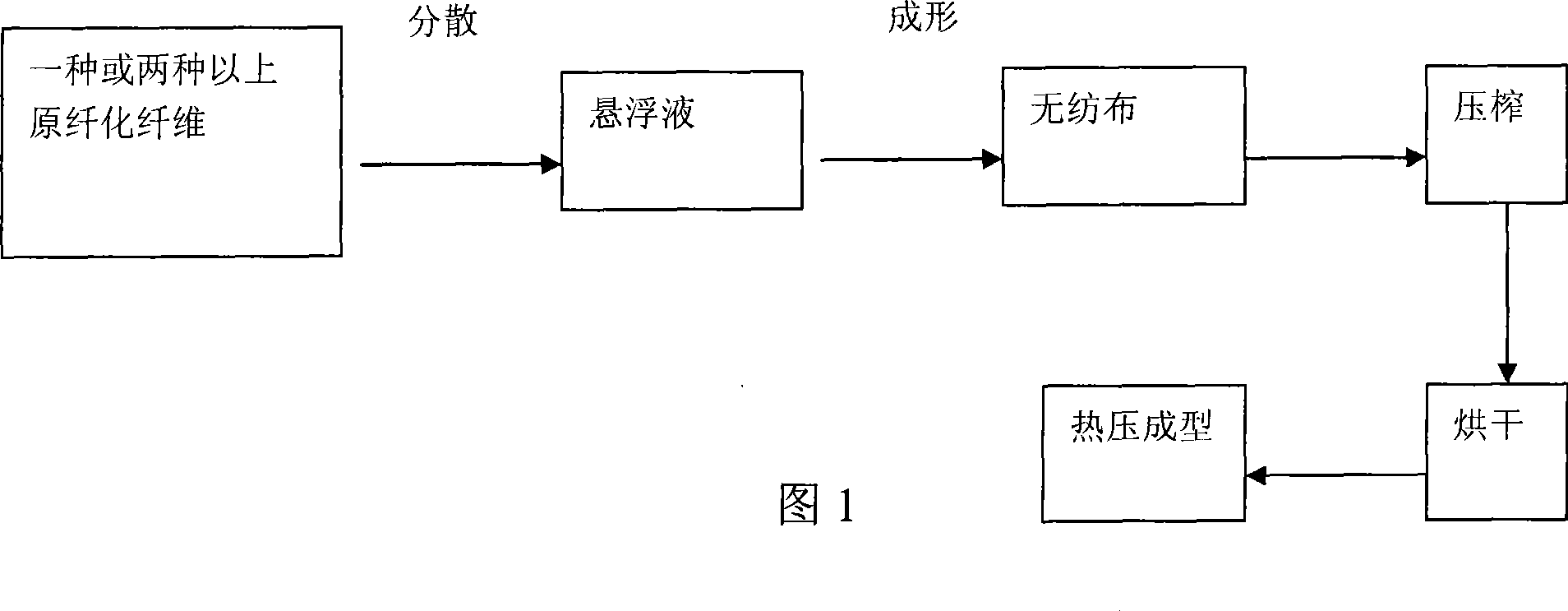

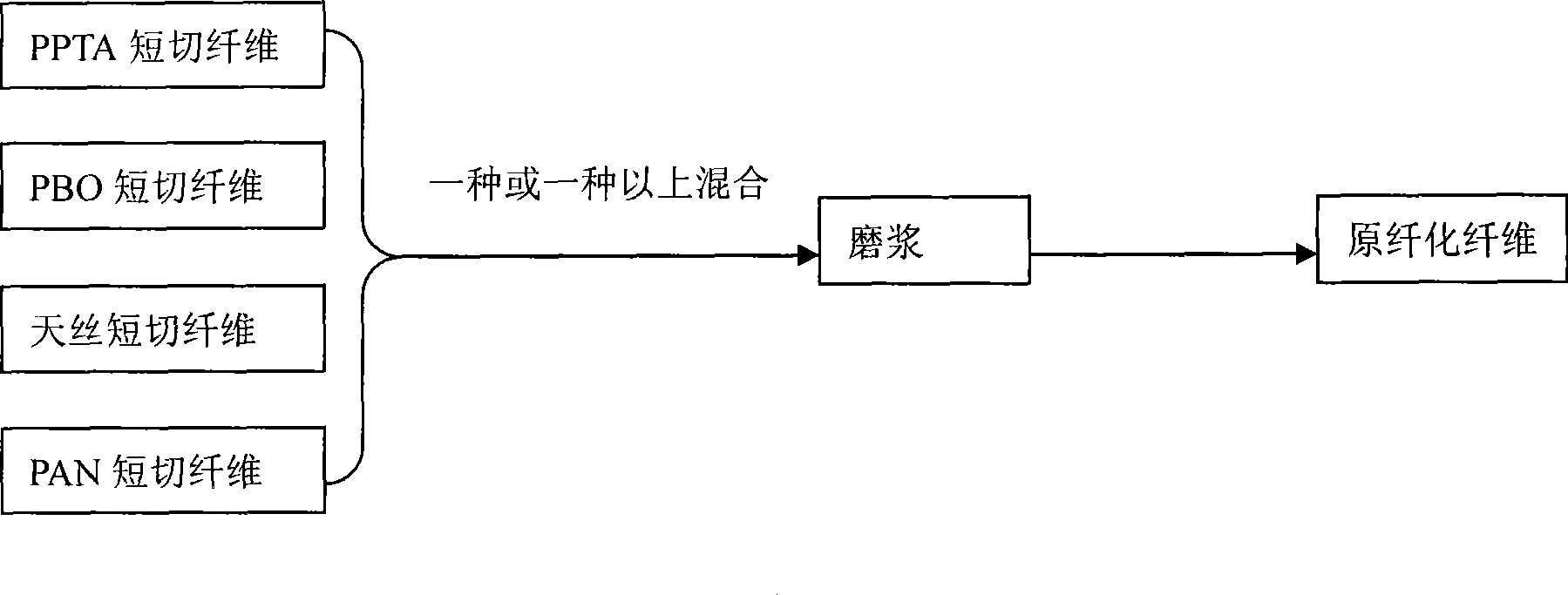

[0034] Fig. 1 is a process flow of the present invention, figure 2 is the flow chart of the preparation of fibrillated fibers. According to this process, the specific implementation steps are as follows:

[0035] (1) Get a certain amount of PBO fibers (trade name: Zylon, produced by Toyobo Corporation in Japan, chopped fibers, length 3mm, diameter 15 μm) with a single-disc refiner to prepare PBO fibrillated fibers with a freeness of 30ml in Canada.

[0036] (2) PBO fibrillated fiber (dry weight 15g / m 2 ), dispersed to obtain a homogeneous suspension.

[0037] (3) Add 15g / m 2 The PP carded non-woven fabric is arranged on the Tappi standard handsheet forming net, and the PBO fibrillated fibers are directly formed on the non-woven fabric, and then dewatered and pressed.

[0038] (4) Dry at 100°C for 5 minutes to prepare 30g / m 2 base paper.

[0039] (5) Hot press the base paper (line pressure 200Kg / cm, temperature 100°C) to prepare filter separation material, its performanc...

Embodiment 2

[0041] In this embodiment, except for the following features, all the other steps are the same as in Embodiment 1.

[0042]In step (1), a certain amount of PBO fiber (trade name: Zylon, produced by Toyobo Corporation in Japan, chopped fiber, length 3mm, diameter 15 μm) is refined with a single disc to prepare the original PBO fiber with a freeness of 80ml in Canada. Fibrillated fibers.

[0043] The properties of the filter separation material obtained in this embodiment are shown in Table 1.

Embodiment 3

[0045] In this embodiment, except for the following features, all the other steps are the same as in Embodiment 1.

[0046] In step (1), a certain amount of PBO fiber (trade name: Zylon, produced by Toyobo Corporation in Japan, chopped fiber, length 3mm, diameter 15 μm) is refined with a single disc to prepare the original PBO fiber with a freeness of 200ml in Canada. Fibrillated fibers.

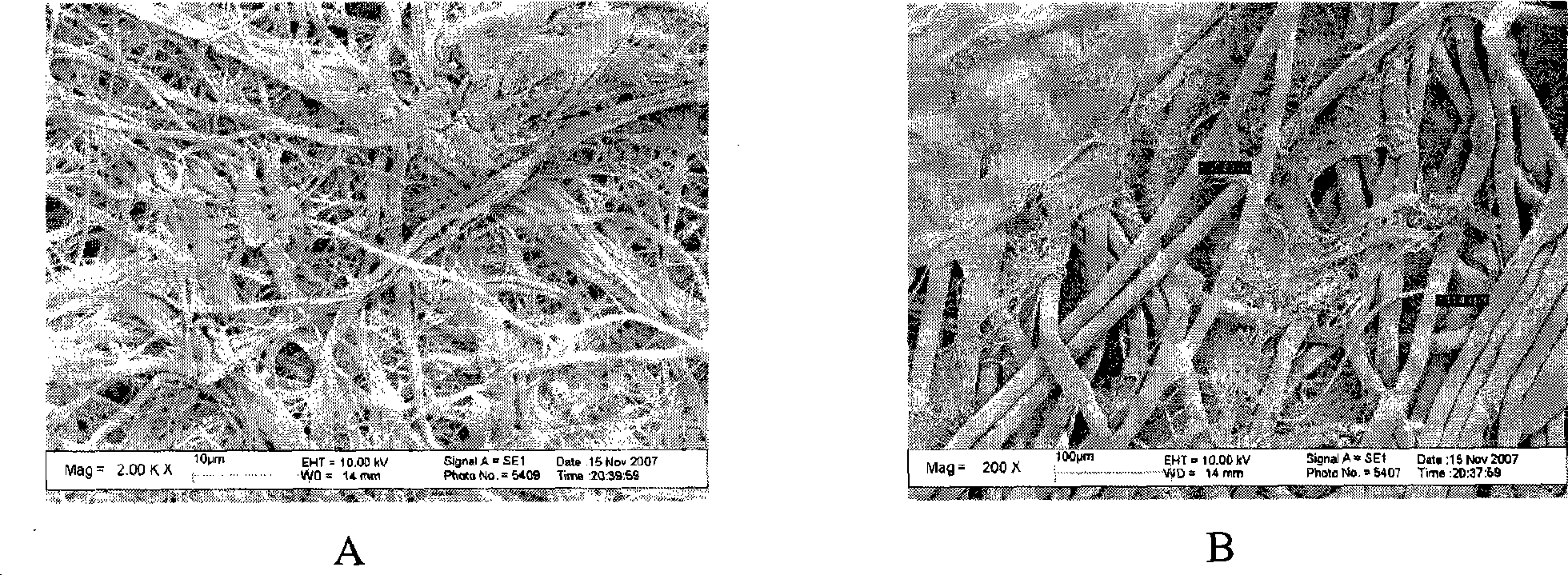

[0047] The electron micrograph of the filter separation material that present embodiment obtains is as Figure 4 (A and B), its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| free rate | aaaaa | aaaaa |

| free rate | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com