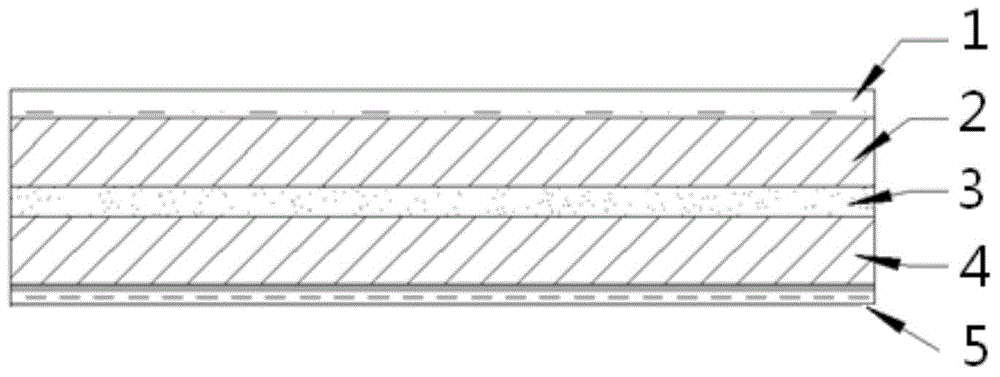

Antibacterial mildewproof glass fiber composite air filter paper and preparation method of antibacterial mildewproof glass fiber composite air filter paper

An air filter paper, glass fiber technology, applied in filter paper, synthetic cellulose/non-cellulose material pulp/paper, filtration and separation, etc., can solve problems such as large market vacancies, increase filtration efficiency and dust holding capacity, prevent The growth of mold and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The method for preparing the antibacterial and mildew-proof glass fiber composite air filter paper in this embodiment comprises the following steps:

[0036] 1) Pulping: Glass fibers with an average diameter of 0.45um are added with H 2 SO 4 beating and dispersing in the aqueous solution, and control the mass concentration of the slurry to be 3.0%, the beating degree is 48°SR, and the acidity is pH=2.5;

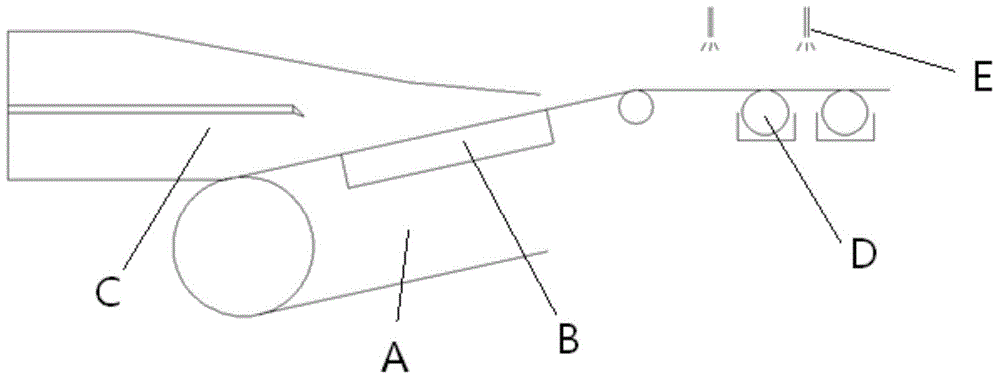

[0037] 2) Wet forming: Dilute the slurry obtained in step 1) to a mass concentration of 0.3%, remove slag, and then add inclined wire forming machine A for wet forming to obtain wet paper;

[0038] 3) Spraying and sizing: the concentration of the antibacterial adhesive solution is 5%, and the antibacterial agent spraying device C is added to the forming net part of the existing manufacturing process, and the wet paper in step 2) is sprayed to make the adhesive evenly distributed on the Between two fiber layers;

[0039] 4) Suction: By means of vacuum suction, use su...

Embodiment 2

[0045] The method for preparing the antibacterial and mildew-proof glass fiber composite air filter paper in this embodiment comprises the following steps:

[0046] 1) Pulping: Glass fibers with an average diameter of 3.2um are added with H 2 SO 4 beating and dispersing in the aqueous solution, and control the mass concentration of the slurry to be 3.5%, the degree of beating is 47°SR, and the acidity is pH=2.3;

[0047] 2) Wet forming: Dilute the slurry obtained in step 1) to a mass concentration of 0.32%, remove the slag, and then add it to inclined wire forming machine A for wet forming to obtain wet paper;

[0048] 3) Spraying and sizing: the concentration of the antibacterial adhesive solution is 3.5%, and the antibacterial agent spraying device C is added to the forming net part of the existing manufacturing process, and the wet paper in step 2) is sprayed to make the adhesive evenly distributed on the Between two fiber layers;

[0049] 4) Suction: By means of vacuum ...

Embodiment 3

[0055] The method for preparing the antibacterial and mildew-proof glass fiber composite air filter paper in this embodiment comprises the following steps:

[0056] 1) Pulping: glass fibers with an average diameter of 5um are added with H 2 SO 4 beating and dispersing in the aqueous solution, and control the mass concentration of the slurry to be 3.2%, the degree of beating is 50°SR, and the acidity is pH=2.4;

[0057] 2) Wet forming: Dilute the slurry obtained in step 1) to a mass concentration of 0.35%, then remove the slag, and then add it to inclined wire forming machine A for wet forming to obtain wet paper;

[0058] 3) Spraying and sizing: the concentration of the antibacterial adhesive solution is 4%, and the antibacterial agent spraying device C is added to the forming net part of the existing manufacturing process, and the wet paper in step 2) is sprayed to make the adhesive evenly distributed on the Between two fiber layers;

[0059] 4) Suction: By means of vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com