A production process of filter paper with high dust holding capacity

A technology of production process and dust holding capacity, which is applied in the field of filter material manufacturing, can solve the problems of reduced air permeability of filter paper and affect filtration efficiency, etc., and achieve the effects of prolonging service life, improving dust holding capacity, good waterproof and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Producing process, specific dust holding capacity paper steps as follows:

[0029] Pulper: The hardwood pulp and softwood pulp in accordance with a certain proportion of the feed into the pulper, pulped wood pulp material are uniformly dispersed in water to obtain a slurry;

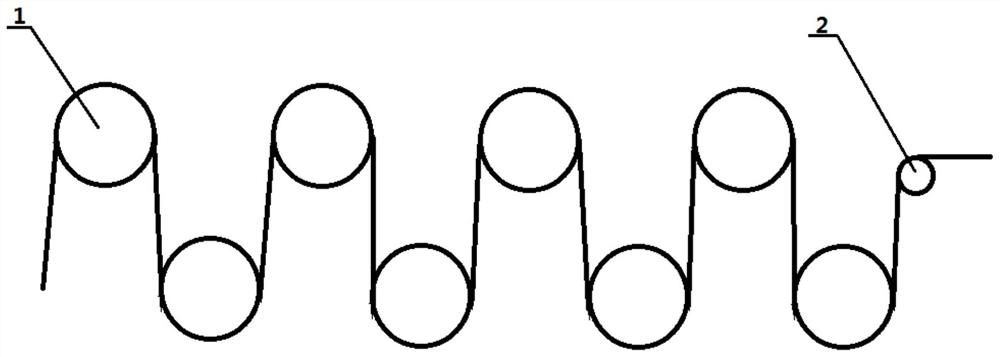

[0030] Wet molding: the slurry through a headbox evenly distributed in the forming wire, and vacuum suction to remove large amounts of water to form a wet sheet;

[0031] Paper Drying: drying the wet paper sheet, obtaining water-free paper, easy to absorb adhesive glue; paper weight after drying was 95 g and a thickness of 0.35 mm, air permeability of 160L / m 2 / S, bursting was 90kpa.

[0032] Gumming dipping: After drying the paper was immersed in an acrylic latex (Viscosity 250cp), the immersion time 1.5s, full penetration of the latex base paper.

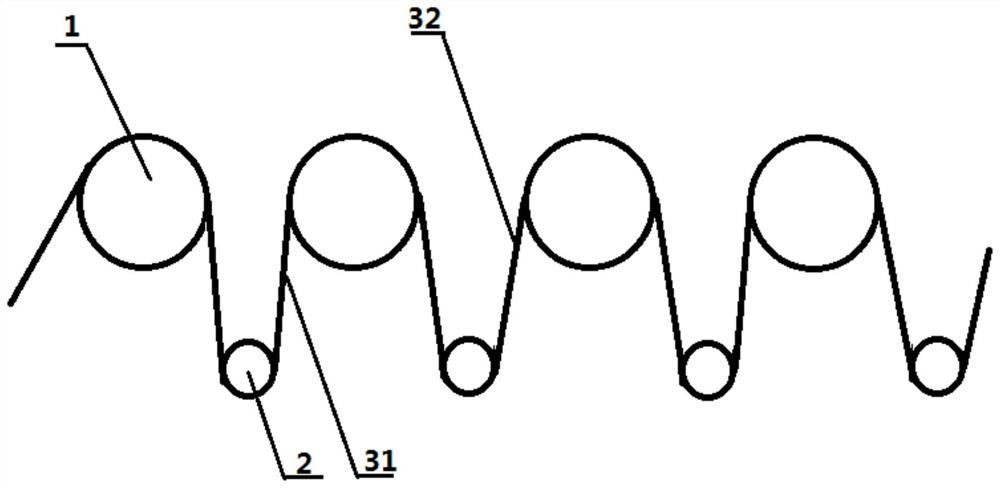

[0033] Drying: The four dryer drying,

[0034] The first group consists of four cylinder dryer, whose temperature was controlled at 160 degrees, betwee...

Embodiment 2

[0041] Producing process, specific dust holding capacity paper steps as follows:

[0042] Pulper: The hardwood pulp and softwood pulp in accordance with a certain proportion of the feed into the pulper, pulped wood pulp material are uniformly dispersed in water to obtain a slurry;

[0043] Wet molding: the slurry through a headbox evenly distributed in the forming wire, and vacuum suction to remove large amounts of water to form a wet sheet;

[0044] Paper Drying: drying the wet paper sheet, obtaining a moisture content of 3wt% of the paper, glue coating to facilitate absorption; paper weight after drying was 115 g and a thickness of 0.45 mm, air permeability of 500L / m 2 / S, bursting was 60kpa.

[0045] Gumming dipping: After drying the paper was immersed in an acrylic latex (viscosity 800 cp), the immersion time 1.5s, full penetration of the latex base paper.

[0046] Drying: Drying dryer using four groups:

[0047] The first dryer group of the dryer 12, whose temperature was ...

Embodiment 3

[0054] Example 2 A base paper obtained in the same embodiment in accordance with the same conditions as impregnation coating dryer group drying four, except that the temperature of each group of drying cylinders, each cylinder through each step of the total drying time and hours are as follows:

[0055] (1) 180 ℃, 5s, 1min;

[0056] (2) 150 ℃, 5s, 0.5min;

[0057] (3) 150 ℃, 5s, 0.5min;

[0058] (4) 140 ℃, 5s, 40s.

[0059] After drying embodiment of the present embodiment grams of filter paper weight, thickness, air permeability and burst strength of Example 2 is quite dust holding capacity of 69g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com