High-throughput continuous gradient fiber volume content preparation method of ceramic matrix composites

A technology of fiber volume and composite materials, which is applied in the field of preparation of ceramic matrix composite materials with high-throughput continuous gradient fiber volume content, can solve the problems of cycle and cost doubling, the influence of development process fluctuations, etc., to achieve sufficient data support, reduce The effect of R&D cost and shortened R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

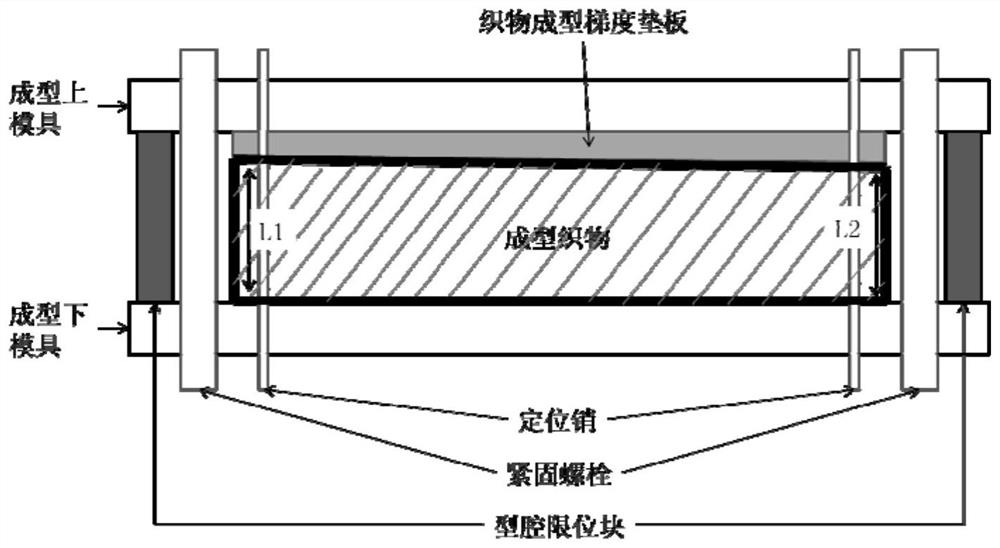

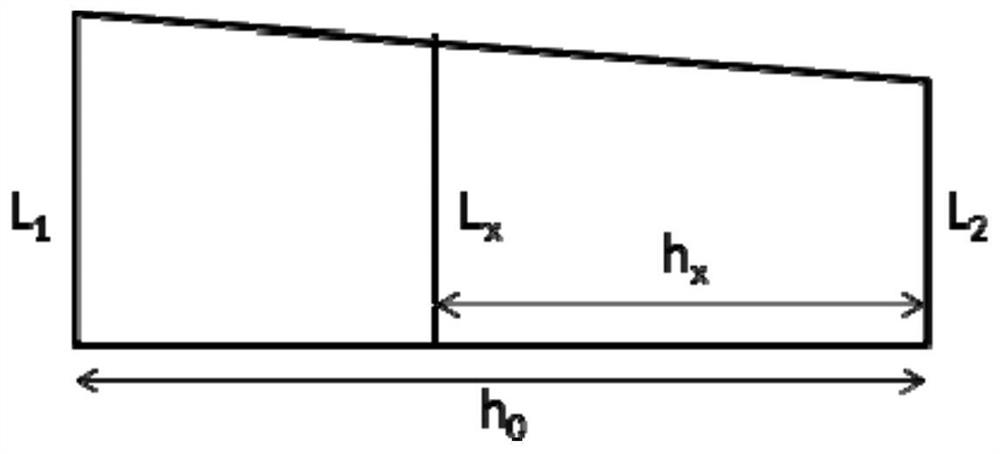

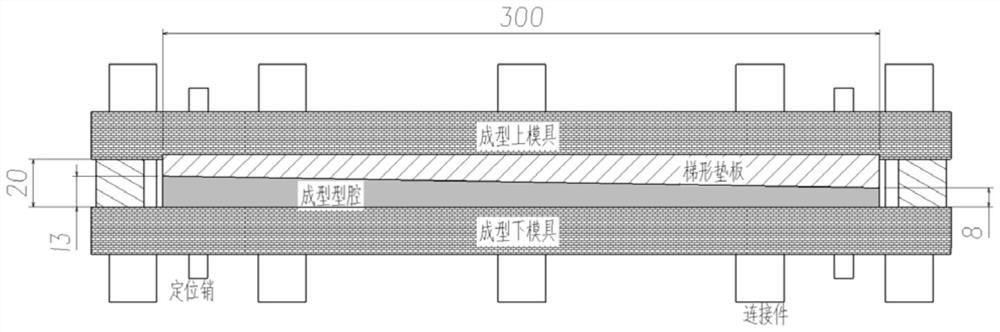

[0058] (1) if image 3 Shown is a schematic diagram of the structure of the shaping tool in Example 1 of the present invention. The composite material shaping tool is designed. The molding cavity of the shaping tool has a gradient change in the thickness direction as a whole, and the gradient change is mainly provided by the trapezoidal backing plate in the cavity. The gradient tooling structure is as follows:

[0059] (a) From the profile of the tooling, the upper surface of the trapezoidal backing plate fits with the upper forming mold, and the lower surface provides a gradient to form the surface of the test piece. The surface of the forming lower mold is parallel to the forming upper mold, without gradient structure. After the trapezoidal backing plate is added between the upper and lower molds, the molding cavity forms a transverse right-angled trapezoidal structure. The lower and upper bottoms of the trapezoid are 13mm and 8mm respectively, which are the maximum and min...

Embodiment 2

[0074] (1) if Figure 4 Shown is a schematic diagram of the structure of the shaping tool in Example 2 of the present invention. The composite material shaping tool is designed. The molding cavity of the shaping tool has a gradient change in the thickness direction as a whole, and the gradient change is mainly provided by the trapezoidal backing plate in the cavity. The gradient tooling structure is as follows:

[0075] (a) From the profile of the tooling, the upper surface of the trapezoidal backing plate fits with the upper forming mold, and the lower surface provides a gradient to form the surface of the test piece. The surface of the forming lower mold is parallel to the forming upper mold, without gradient structure. After the trapezoidal backing plate is added between the upper and lower molding molds, the molding cavity forms a transverse right-angle trapezoidal structure, and the lower and upper bottoms of the trapezoid are 12mm and 10mm respectively, which are the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com