Preparation method of single-crystal high-nickel positive electrode material, product and application thereof

A positive electrode material and single crystal technology, which is applied in the field of preparation of single crystal high-nickel positive electrode materials, can solve the problems of material performance deterioration, high impurity content of nickel-cobalt-lithium-aluminate materials, etc., and achieve the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

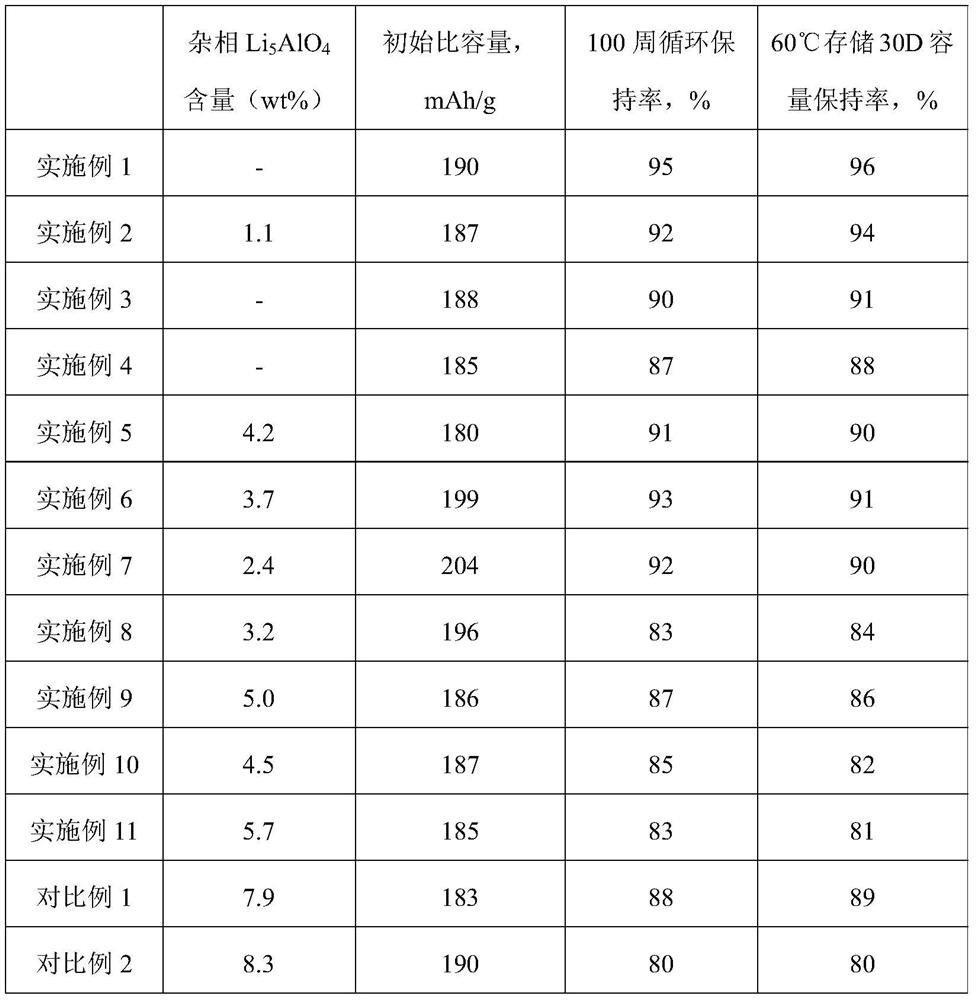

Examples

Embodiment 1

[0064] The single crystal high-nickel positive electrode material described in this embodiment is LiNi 0.85 co 0.075 al 0.075 o 2 ; Its preparation method comprises the following steps:

[0065] (I) Precursor preparation, specifically including the following steps:

[0066] The solution of the nickel source and the cobalt source that the metal ion concentration is 2mol / L, the sodium hydroxide solution that the concentration is 4mol / L and the ammoniacal liquor that the concentration is 10wt% are mixed according to the ratio of 2:4:1.5 according to the volume ratio, adjust pH as 12.7, react at a temperature of 60°C and a stirring rate of 300 rpm for 15 hours, filter, wash, and dry to obtain a nickel-cobalt precursor with a particle size D50 of 5 μm;

[0067] (II) The precursor in step (I) and lithium hydroxide are mixed and ball milled at a molar ratio of 1:1.05. Under an oxygen atmosphere, the temperature is raised to 850°C at a heating rate of 5°C / min and calcined for 10h ...

Embodiment 2

[0070] The difference between this example and Example 1 is that the calcination temperature in step (II) is replaced by 900° C., and other parameters and conditions are exactly the same as those in Example 1.

Embodiment 3

[0072] The difference between this example and Example 1 is that the calcination temperature in step (II) is replaced by 800° C., and other parameters and conditions are exactly the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com