A catalytic filter element and its preparation method and device and application of the device

A filter element and nano-catalyst technology, which is applied in the field of low temperature flue gas purification, can solve the problems of great influence on the activity and service life of the catalytic filter element, uneven coating of the catalyst, large energy consumption of the catalyst, etc. Improve the effect of implantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

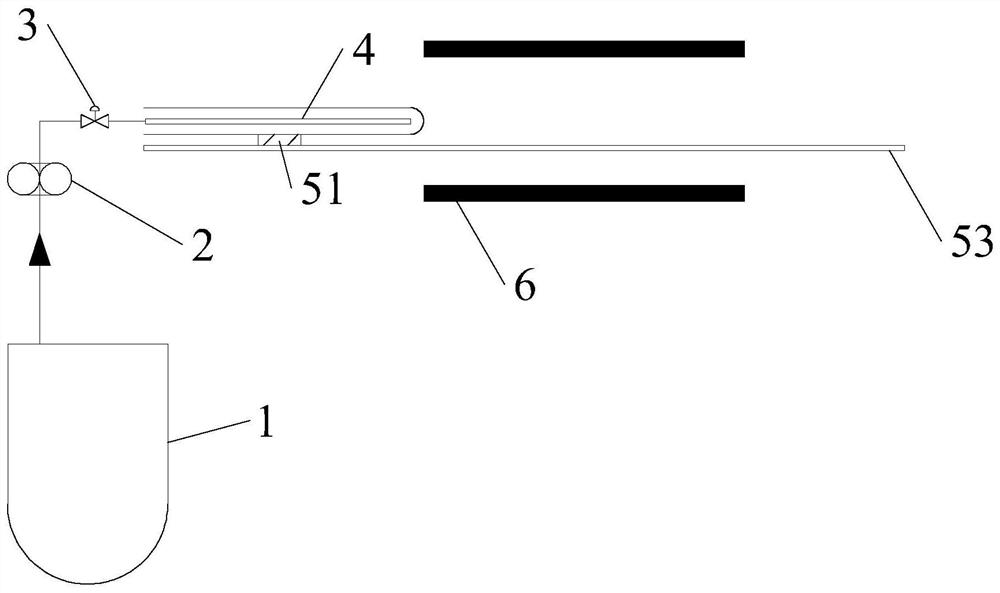

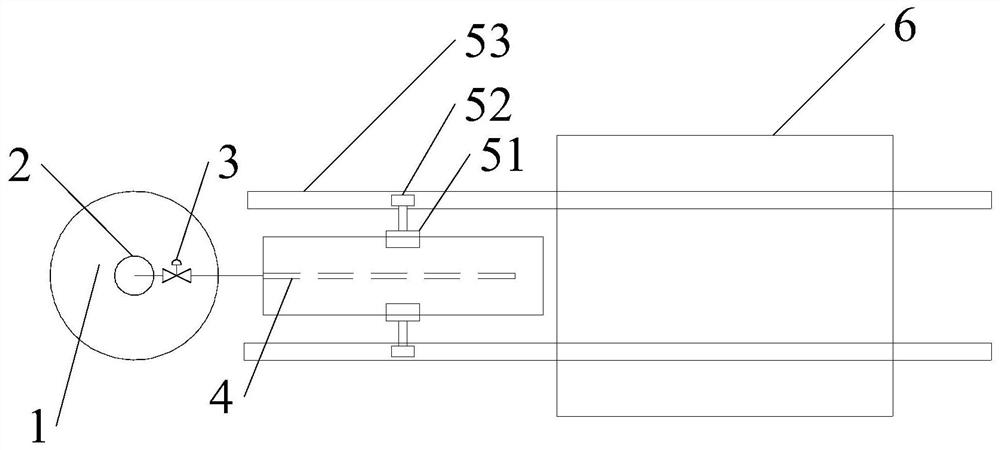

[0055] This embodiment provides a device for preparing a catalytic filter element, the structural schematic diagram of the device is as follows figure 1 and figure 2 As shown, the device includes: a slurry storage unit, a slurry injection unit, a filter element fixing unit and a heating unit.

[0056] An advection pump 2 is arranged between the slurry storage unit and the slurry injection unit, the slurry storage unit is a stirring slurry tank 1, and the slurry injection unit includes a porous slurry injection pipe 4 and an electric valve 3, The inlet of the horizontal flow pump 2 is connected with the outlet of the stirring slurry tank 1 , and the outlet of the horizontal flow pump 2 is connected with the porous slurry injection pipe 4 through the electric valve 3 .

[0057] The filter core fixing unit includes a top-down round roller 51, a moving pulley 52 and a support bracket 53. There are two round rollers 51, one of which is connected with a motor, and the other round ...

Embodiment 2

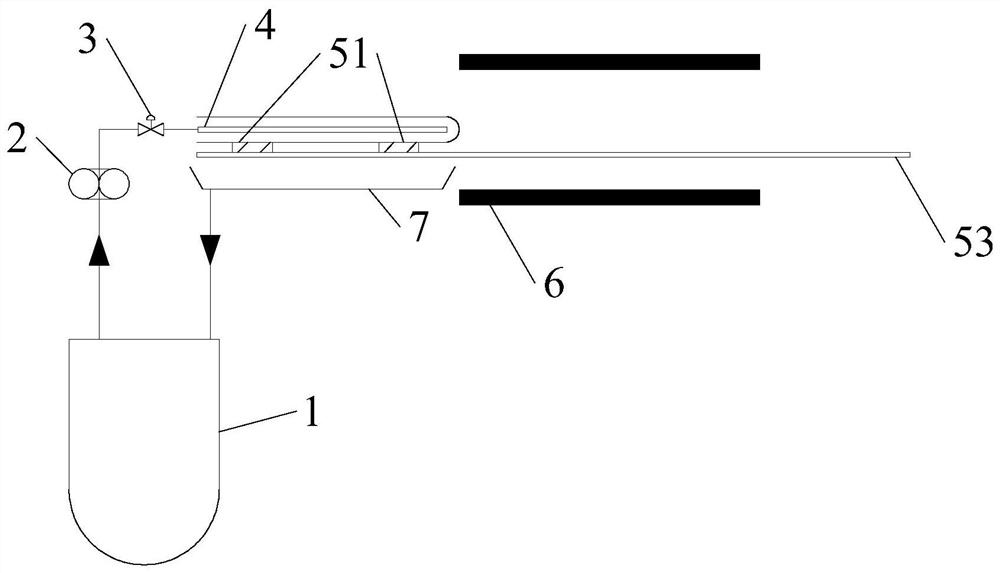

[0060] This embodiment provides a device for preparing a catalytic filter element, the structural schematic diagram of the device is as follows image 3 and Figure 4 As shown, the device includes: a slurry storage unit, a slurry injection unit, a filter element fixing unit and a heating unit.

[0061] An advection pump 2 is arranged between the slurry storage unit and the slurry injection unit, the slurry storage unit is a stirring slurry tank 1, and the slurry injection unit includes a porous slurry injection pipe 4 and an electric valve 3, The inlet of the horizontal flow pump 2 is connected with the outlet of the stirring slurry tank 1 , and the outlet of the horizontal flow pump 2 is connected with the porous slurry injection pipe 4 through the electric valve 3 .

[0062] The filter element fixing unit includes a top-down round roller 51, a moving pulley 52 and a support bracket 53, the number of round rollers 51 is four, one of which is connected with a motor, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com