Copper indium gallium sulfide selenide solar cell, thin film absorber layer and preparation method thereof

A technology of copper indium gallium sulfide selenide and absorbing layer, which is applied in the field of solar photovoltaics, can solve the problems of CIGS absorbing layer structure is not dense, restricting large-scale use, strong toxicity and corrosion, and achieves low equipment requirements, compact structure, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

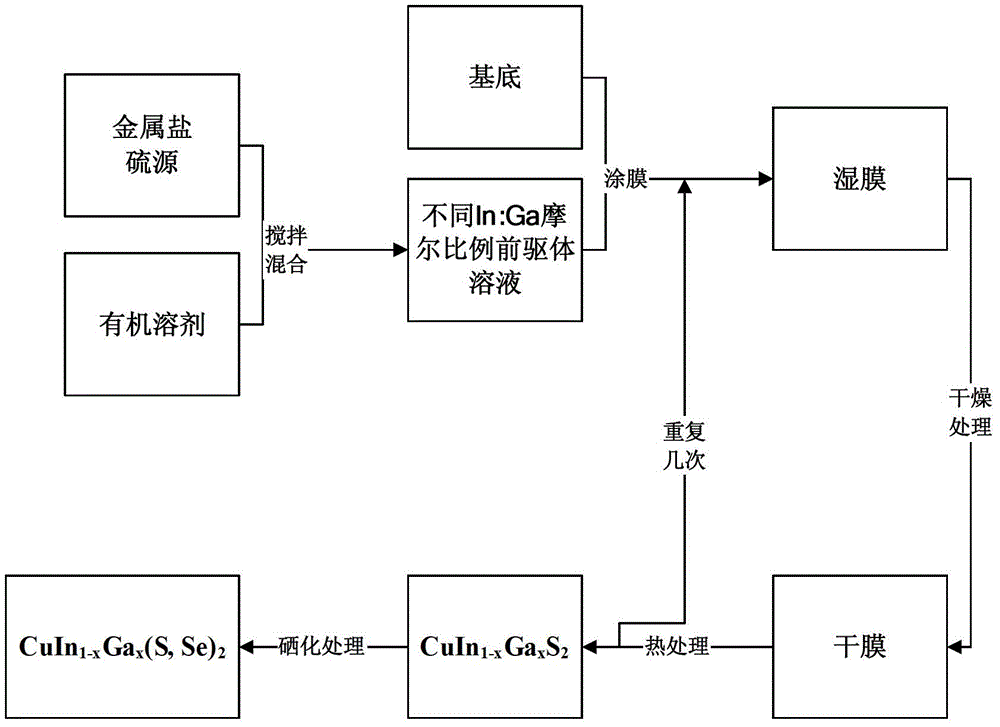

[0029] Such as figure 1 As shown, the copper indium gallium sulfide selenium thin film absorption layer preparation method of the present application, an implementation thereof, comprises the following steps:

[0030] Step 1. Prepare precursor solution:

[0031] Dissolve copper, indium and gallium chloride, acetate or copper acetylacetonate in an organic solvent, add a sulfur source, and stir to obtain a uniform precursor solution, wherein the molar ratio of Cu:In:Ga:S is ( 0.8~1):(0.63~0.8):(0.2~0.37):(2~2.5);

[0032] In one embodiment, copper, indium and gallium chloride, acetate or acetylacetonate can be dissolved in organic solvents such as pyridine, dimethyl sulfoxide, 1-butylamine, and then thiourea or Carbon disulfide is used as a sulfur source, and after stirring at room temperature for 0.5-2 hours, a homogeneous solution is obtained, wherein the molar ratio of Cu:In:Ga:S is (0.8-1):(0.63-0.8):(0.2-0.37):( 2~2.5), the concentration of metal ions is 0.1~0.8mol / L.

...

Embodiment 1

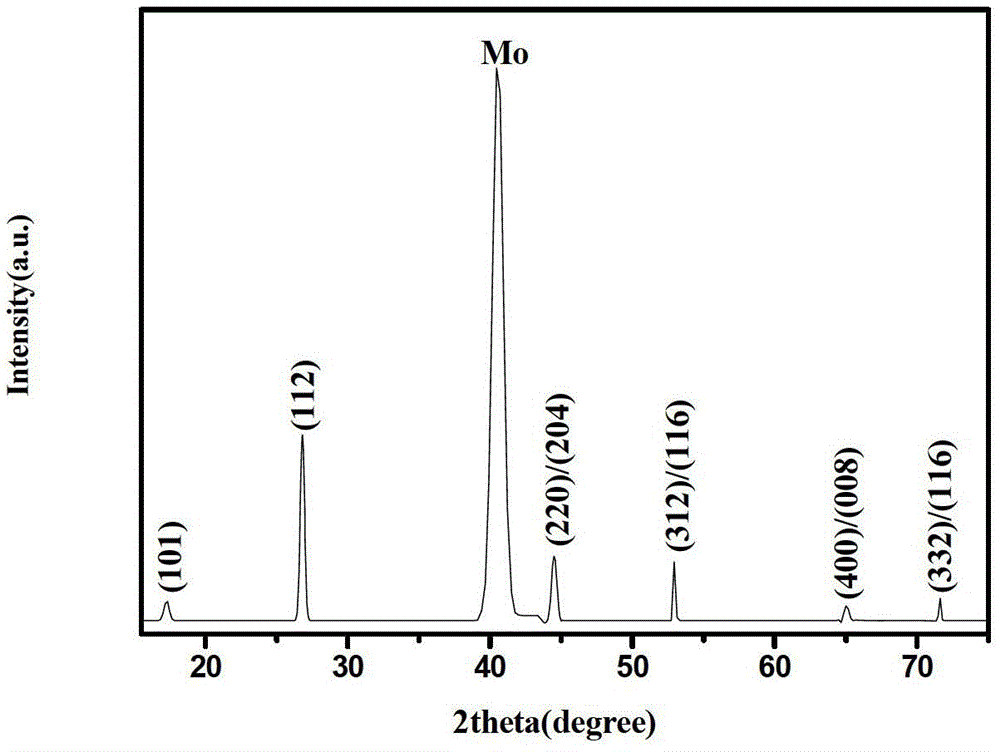

[0047] Copper acetate, indium chloride, gallium acetylacetonate and thiourea are used as raw materials, and the raw materials are weighed according to the Cu:In:Ga:S molar ratio of 1:0.7:0.3:2.2. The weighed raw materials were dissolved in pyridine, and the amount of solvent used was adjusted so that the metal ion concentration was 0.1M. After magnetic stirring for 60 min, a uniform solution with a certain viscosity was obtained. Precursor films were prepared on Mo-coated soda-lime glass by spin coating, and then dried at 200°C for 10 minutes to change the molar ratio of In:Ga. Repeat the above steps several times to obtain a precursor film with a thickness of 1.5-2 μm. . Finally, the precursor film was put into a tube furnace for heat treatment under N2 atmosphere, the heat treatment temperature was 450°C, and the heat treatment time was 15 minutes to obtain CuIn 0.7 Ga 0.3 S 2 film. CuIn 0.7 Ga 0.3 S 2 The film is selenized in a selenization furnace, the selenium sou...

Embodiment 2

[0049] Copper acetate, indium chloride, gallium chloride and thiourea are used as raw materials, and the raw materials are weighed according to the Cu:In:Ga:S molar ratio of 0.9:0.7:0.3:2.2. The weighed raw materials were dissolved in dimethyl sulfoxide solvent, and the amount of solvent was adjusted so that the total concentration of metal ions was 0.8M. After magnetic stirring for 30 min, a uniform and stable solution was obtained. The precursor film was prepared on the Mo-coated soda-lime glass by spin coating, and the subsequent steps were the same as in Example 1 for drying and heat treatment to obtain a CIGS film. Finally, put the film into a selenization furnace for selenization treatment. The selenium source used is solid high-purity Se powder, and the temperature of the selenium source is 230 ° C, N 2 The flow rate is 0.2m 3 / h, the selenization temperature is 400°C, and the selenization time is 30min. After selenization treatment, the CIGSSe thin film is prepared....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com