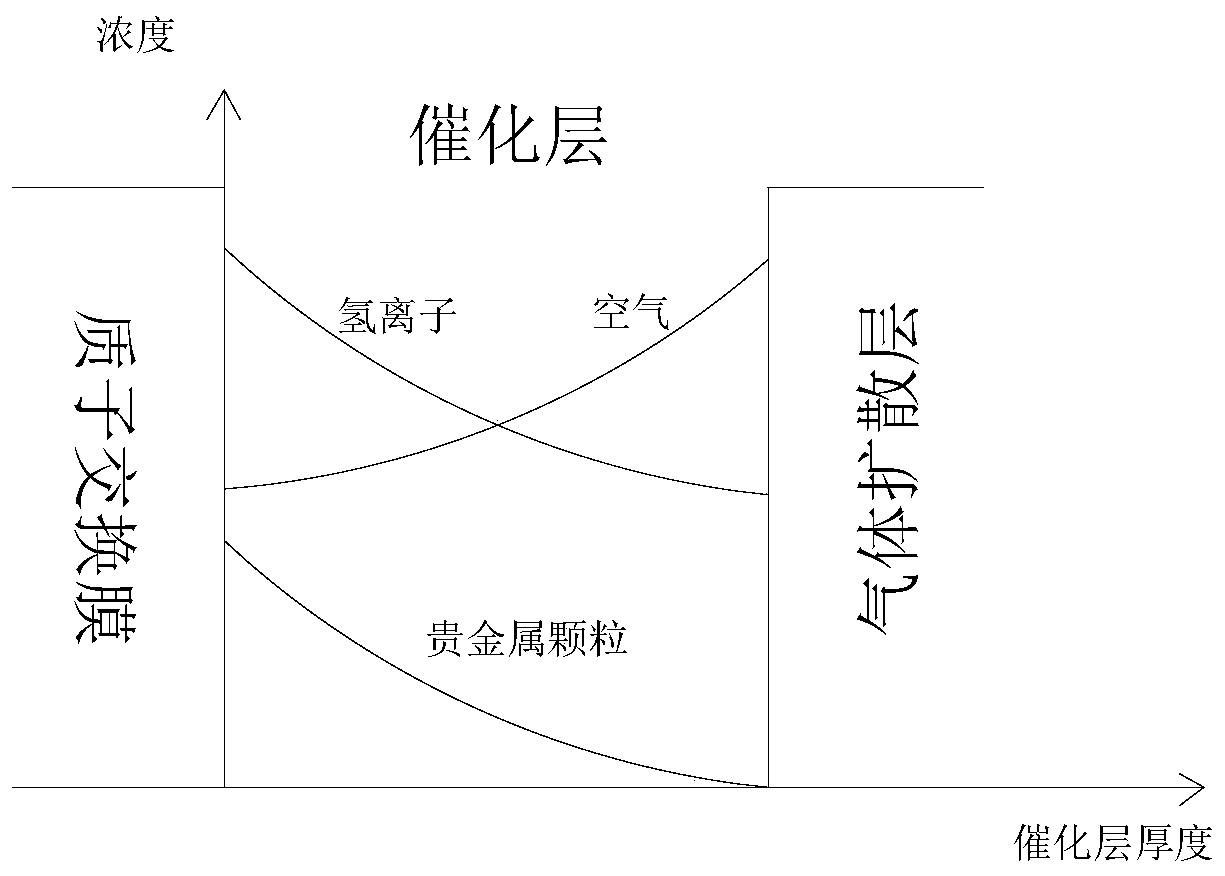

A kind of mea preparation method that noble metal catalyst particles are distributed in gradient

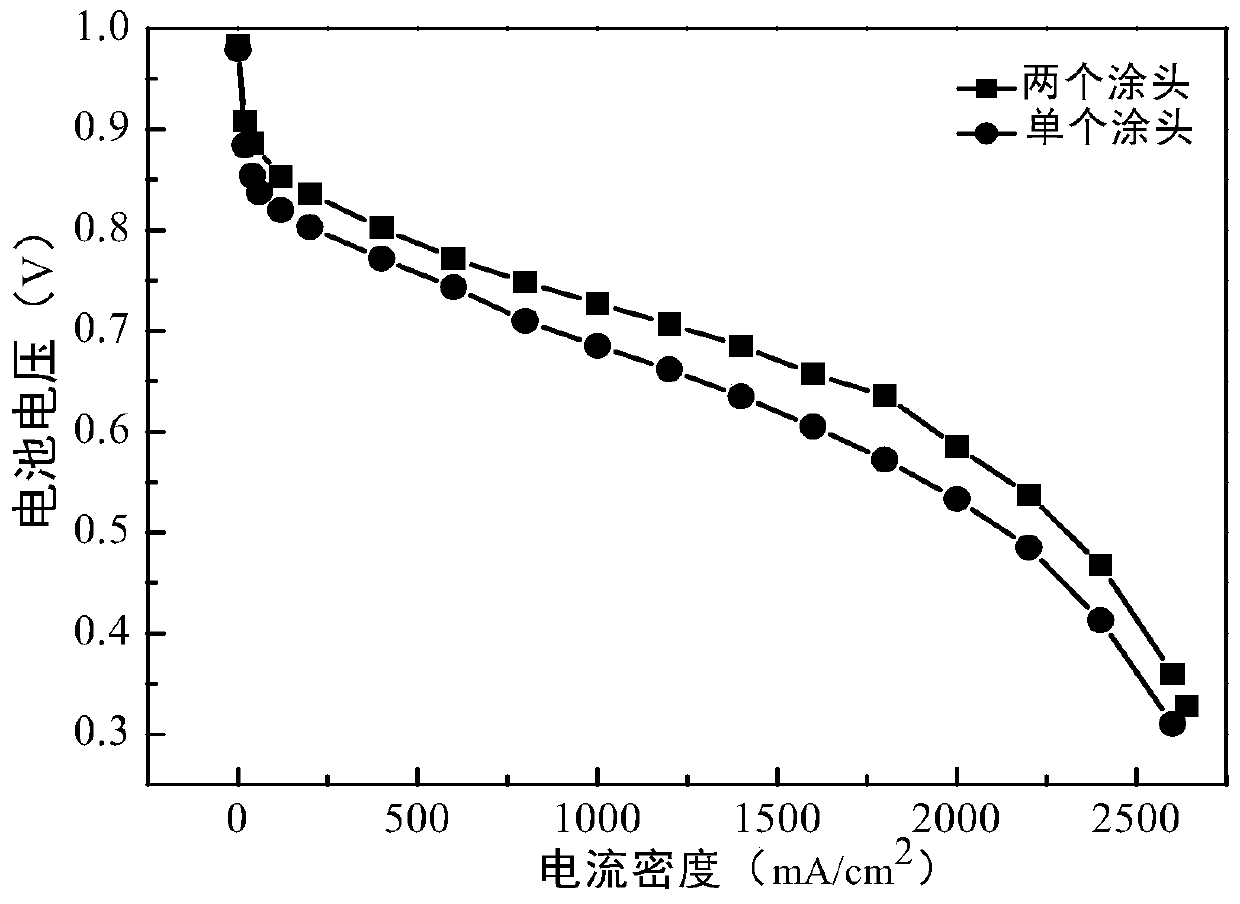

A precious metal catalyst, gradient distribution technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of waste, failure to achieve gradient distribution of precious metal catalyst particles, and high cost of membrane electrode assemblies, to avoid waste and meet small batch production. , Coating efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

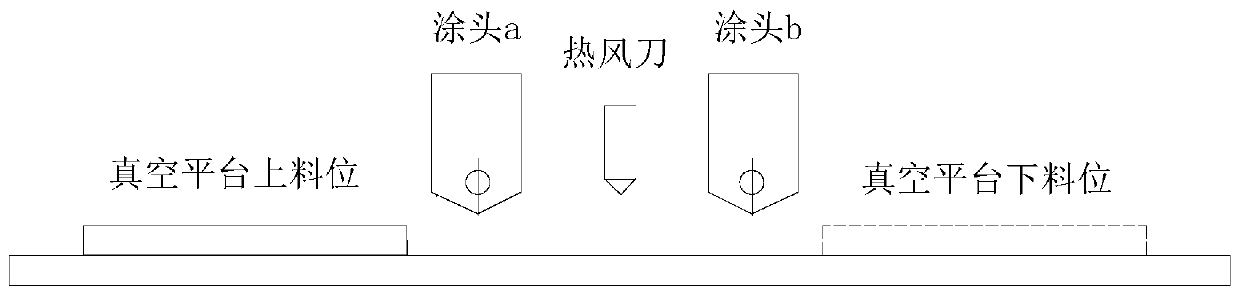

[0029] In this example, a membrane electrode assembly (MEA) is prepared by a knife coating process. The precious metal catalyst particles are coated on the membrane in two layers, and are coated by a coating machine. Refer to the schematic diagram of the coating head and coating position of the coating machine. image 3 ,Specific steps are as follows:

[0030] Preparation of catalytic layer slurry a, by weight 60wt.%Pt / C: 5wt.% Monomer solution: isopropanol: deionized water = 14:6:38:40, and stirred at room temperature for 1 hour.

[0031] Preparation of catalytic layer slurry b, by weight 60wt.%Pt / C: 5wt.% Monomer solution: isopropanol: deionized water = 8:3:38:40 Prepare and stir at room temperature for 1 hour.

[0032] Move the vacuum coating platform to the upper material position, cut the proton exchange membrane according to a certain size, put it on the vacuum platform, and turn on the vacuum device.

[0033] Rotate the slit extrusion coating head a to the vertical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com