High-temperature radar infrared compatible stealth coating with functional gradient distribution and preparation method thereof

A functional gradient, high temperature technology, applied in coatings, layered products, chemical instruments and methods, etc., can solve problems such as poor oxidation resistance, achieve good thermal shock resistance, improve resistivity, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

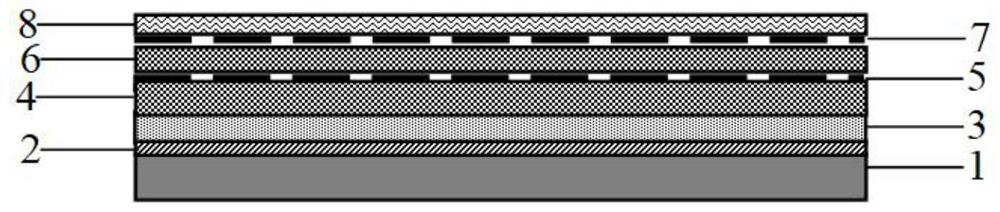

[0040] A functional gradient distribution high temperature radar infrared compatible stealth coating such as figure 1 As shown, it is coated on the surface of the metal substrate 1. The metal substrate is a superalloy GH4169. Starting from the surface of the superalloy GH4169, it includes a metal bonding layer 2, a thermally matching ceramic layer 3, a dielectric ceramic layer 4, and a second layer from bottom to top. A high temperature electromagnetic periodic structure layer 5 , a dielectric isolation layer 6 , a second high temperature electromagnetic periodic structure layer 7 , and an infrared stealth layer 8 . The metal bonding layer is a CoNiCrAlY coating with a thickness of 0.05 mm. The heat matching ceramic layer is yttria-stabilized zirconia coating, the molar ratio of yttria is 8%, and the thickness is 0.2mm. The dielectric ceramic layer is an alumina coating with a thickness of 0.72mm. The first high-temperature electromagnetic periodic structure layer is in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com