Gradient ultrahigh-temperature ceramic-based composite material and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of gradient ultra-high temperature ceramic matrix composite materials and its preparation, can solve the problems of affecting product weight, large difference in inner and outer densities, and large deviation of expansion coefficients of inner and outer layers, etc. Designability, excellent high temperature ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

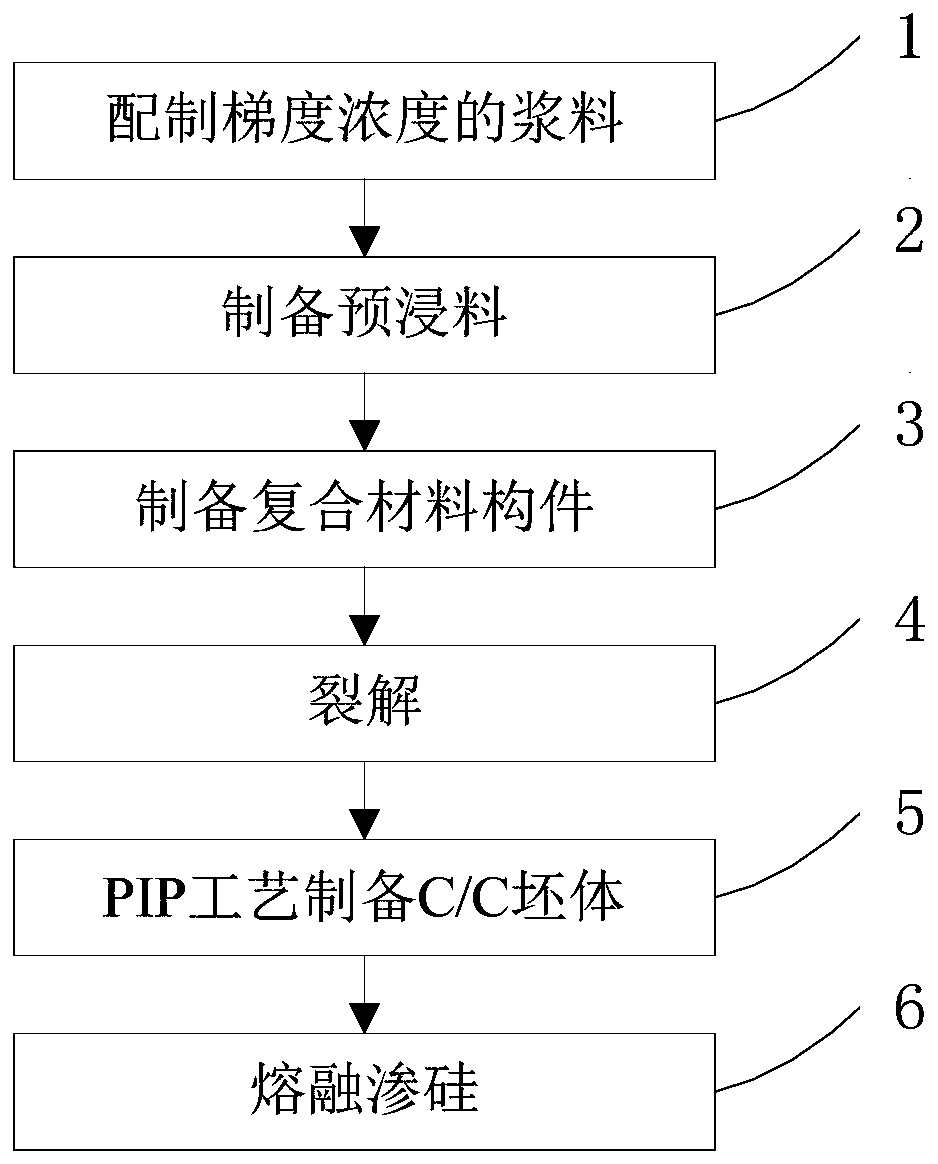

[0033] The invention provides a preparation method of a gradient ultra-high temperature ceramic matrix composite material, such as figure 1 shown, including the following steps:

[0034] (1) Preparation of slurry with gradient concentration

[0035] The solid component is zirconium carbide powder, the liquid component is thermosetting phenolic resin, and the solid component and the liquid component are mixed to prepare n slurry with gradient concentration, wherein n≥2.

[0036] The thermosetting resin is preferably barium phenolic resin. The particle size of the zirconium carbide powder is 0.5-4 μm. Too small particles will increase the cost, and too large particles will affect the subsequent preparation process. It is more preferably 1-3 μm, for example, it can be 1 μm, 2 μm, or 3 μm.

[0037] The gradient concentration scope of described slurry is preferably 10~60% (for example, can be 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 55%, 60%) ), that is, the mass percentage ...

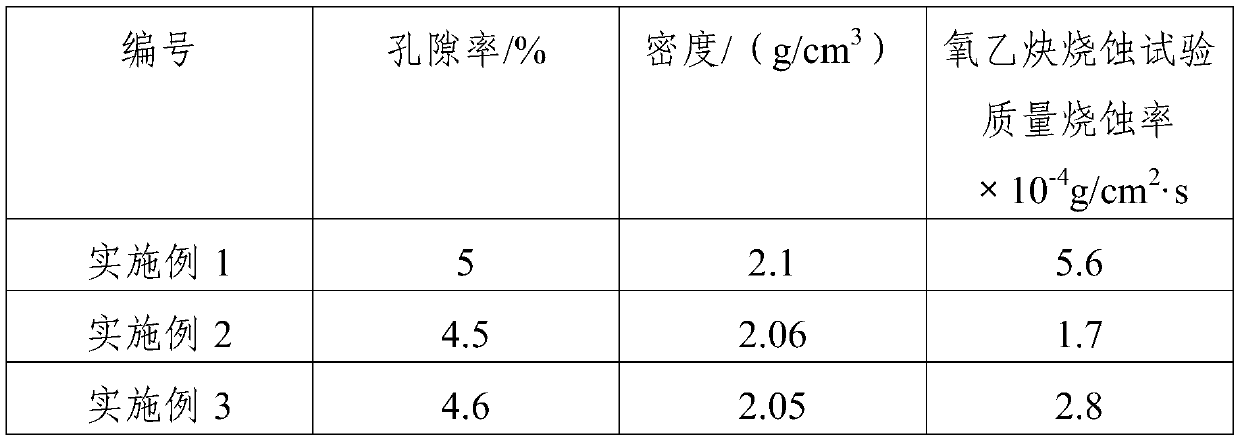

Embodiment 1

[0070] (1) Preparation of slurry with gradient concentration

[0071] The solid component uses zirconium carbide powder with a particle size of 4 μm, and the liquid component uses aminophenol-formaldehyde resin. The solid component and the liquid component are mixed to prepare two gradient concentrations of slurry, which are: ① Powder content 10wt.% slurry, ② 60wt.% powder slurry.

[0072] (2) Preparation of prepreg

[0073] Using hot-melt adhesive film method, two formulations of phenolic resin slurry were compounded with carbon cloth respectively to prepare prepregs with two powder contents, wherein the mass content of resin slurry in the prepreg was 60%.

[0074] (3) Preparation of composite material components

[0075] Lay multiple prepregs prepared in step (2), control the fiber volume fraction of the product to 40% through the number of layers, and realize the gradient of ceramic powder in the low-density green body by laying prepregs with different powder contents , ...

Embodiment 2

[0085] (1) Preparation of slurry with gradient concentration

[0086] The solid component uses zirconium carbide powder with a particle size of 4 μm, and the liquid component uses aminophenol-formaldehyde resin. The solid component and the liquid component are mixed to prepare two gradient concentrations of slurry, which are: ① Powder content 20wt.% slurry, ② 40wt.% powder slurry.

[0087] (2) Preparation of prepreg

[0088] Using hot-melt adhesive film method, two formulations of phenolic resin slurry were compounded with carbon cloth respectively to prepare prepregs with two powder contents, wherein the mass content of resin slurry in the prepreg was 60%.

[0089] (3) Preparation of composite material components

[0090] Lay multiple prepregs prepared in step (2), control the fiber volume fraction of the product to 40% through the number of layers, and realize the gradient of ceramic powder in the low-density green body by laying prepregs with different powder contents , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com