Method for producing HfC-SiC multiphase gradient coating layer by chemical vapor co-deposition technology

A chemical vapor phase, gradient coating technology, applied in the field of preparation of HfC-SiC multiphase gradient coating, can solve problems such as thermal expansion mismatch, and achieve the effects of alleviating thermal stress, short reaction period and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

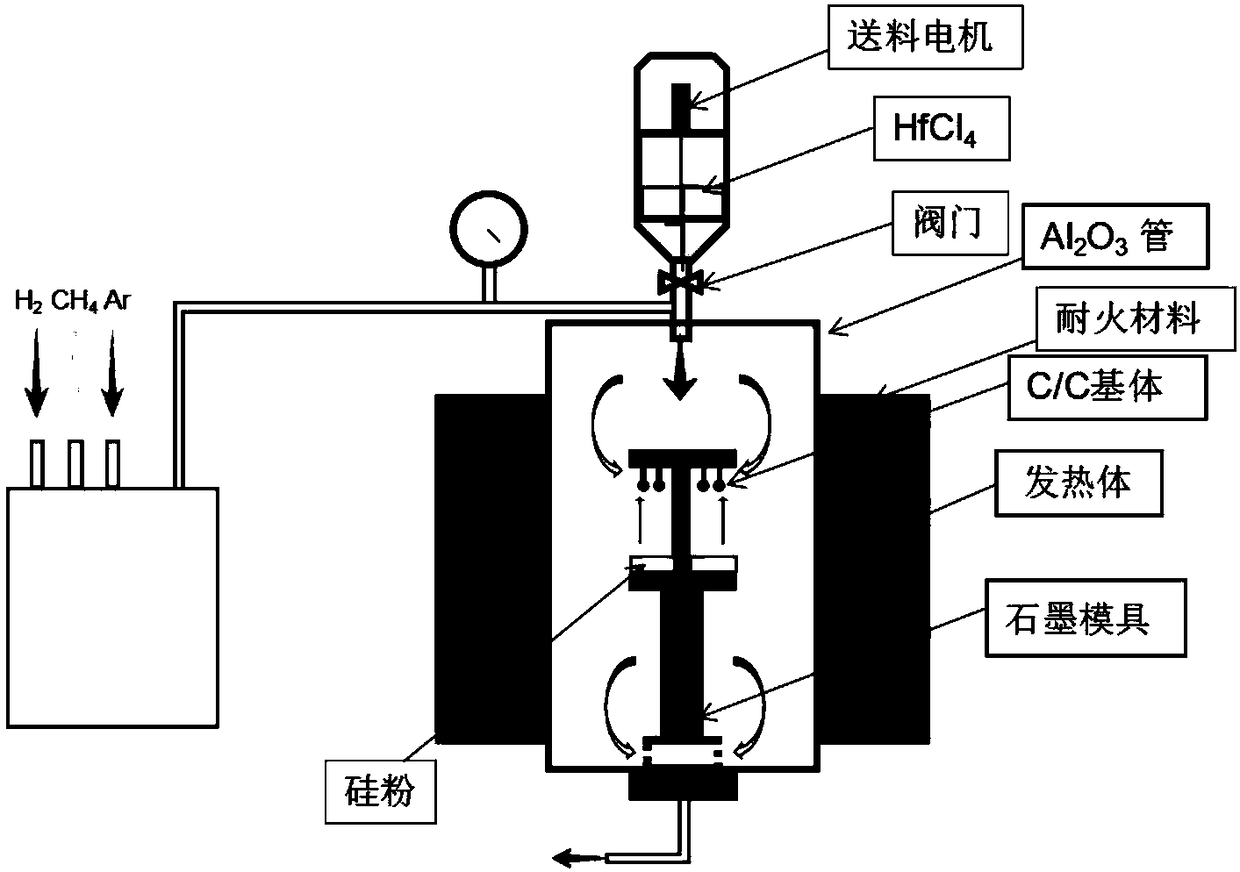

[0023] The selected density is 1.75g / cm 3 The C / C composite material is used as the matrix, and HfCl is selected 4 , CH 4 / C 3 h 6 , Si as a precursor, using chemical vapor co-deposition technology at 1500 ° C, with H 2 The HfC-SiC multiphase gradient coating was prepared as the reducing gas and Ar as the dilution and protective gas.

[0024] The prepared C / C substrate was polished with 340-mesh wet sandpaper, and then ultrasonically cleaned with deionized water at room temperature (25°C) for 5 minutes. After cleaning twice, it was placed in a blast oven at 80°C. Dry for 4 hours, take out and set aside. Place the prepared C / C substrate in the isothermal zone of the vertical isothermal chemical vapor deposition furnace, and then add HfCl 4 The powder is placed in the feeding device, and the Si powder is placed in the stocker below the isothermal zone (such as figure 1 As shown), the deposition temperature is set to 1500°C, the heating rate is 7.0°C / min to ensure that the...

Embodiment 2

[0026] The selected density is 1.75g / cm 3 The C / C composite material is used as the matrix, and HfCl is selected 4 , CH 4 / C 3 h 6 , Si as a precursor, using chemical vapor co-deposition technology at 1400 ° C, with H 2 The HfC-SiC multiphase gradient coating was prepared as the reducing gas and Ar as the dilution and protective gas.

[0027] The prepared C / C substrate was polished with 340-mesh wet sandpaper, and then ultrasonically cleaned with deionized water at room temperature (25°C) for 5 minutes. After cleaning twice, it was placed in a blast oven at 80°C. Dry for 4 hours, take out and set aside. Place the prepared C / C substrate in the isothermal zone of the vertical isothermal chemical vapor deposition furnace, and then add HfCl 4 The powder is placed in the feeding device, and the Si powder is placed in the stocker below the isothermal zone (such as figure 1 As shown), set the deposition temperature to 1400°C, the heating rate to 7.0°C / min, to ensure that the p...

Embodiment 3

[0029] The selected density is 1.75g / cm 3 The C / C composite material is used as the matrix, and HfCl is selected 4 , CH 4 / C 3 h 6 , Si as a precursor, using chemical vapor co-deposition technology at 1300 ° C, with H 2 The HfC-SiC multiphase gradient coating was prepared as the reducing gas and Ar as the dilution and protective gas.

[0030] The prepared C / C substrate was polished with 340-mesh wet sandpaper, and then ultrasonically cleaned with deionized water at room temperature (25°C) for 5 minutes. After cleaning twice, it was placed in a blast oven at 80°C. Dry for 4 hours, take out and set aside. Place the prepared C / C substrate in the isothermal zone of the vertical isothermal chemical vapor deposition furnace, and then add HfCl 4 The powder is placed in the feeding device, and the Si powder is placed in the stocker below the isothermal zone (such as figure 1 As shown) set the deposition temperature to 1300°C, the heating rate to 7.0°C / min, to ensure that the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com