Zeolite roller capable of intensively treating exhaust gas

A zeolite runner and exhaust gas technology, which is applied in the direction of gas treatment, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of uneven adsorption, poor adsorption effect, and poor adsorption effect of zeolite runners, and improve waste gas treatment. effect, improve the adsorption path, improve the effect of the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

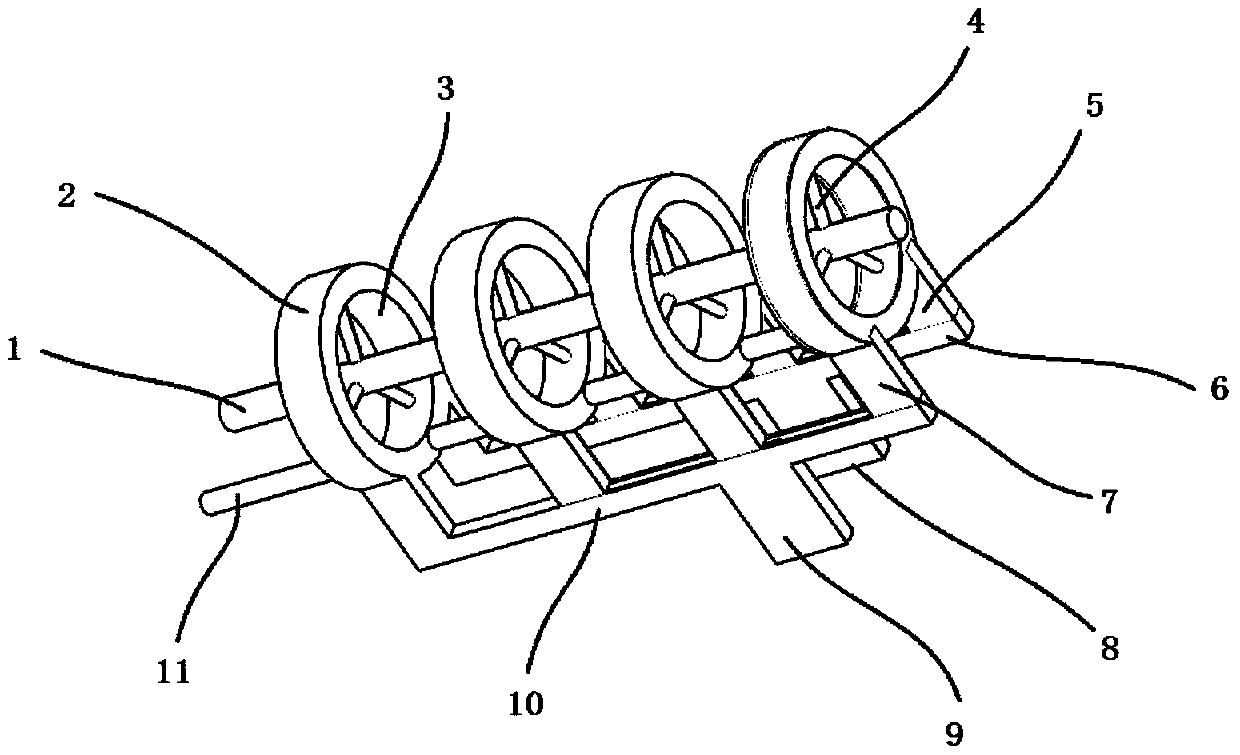

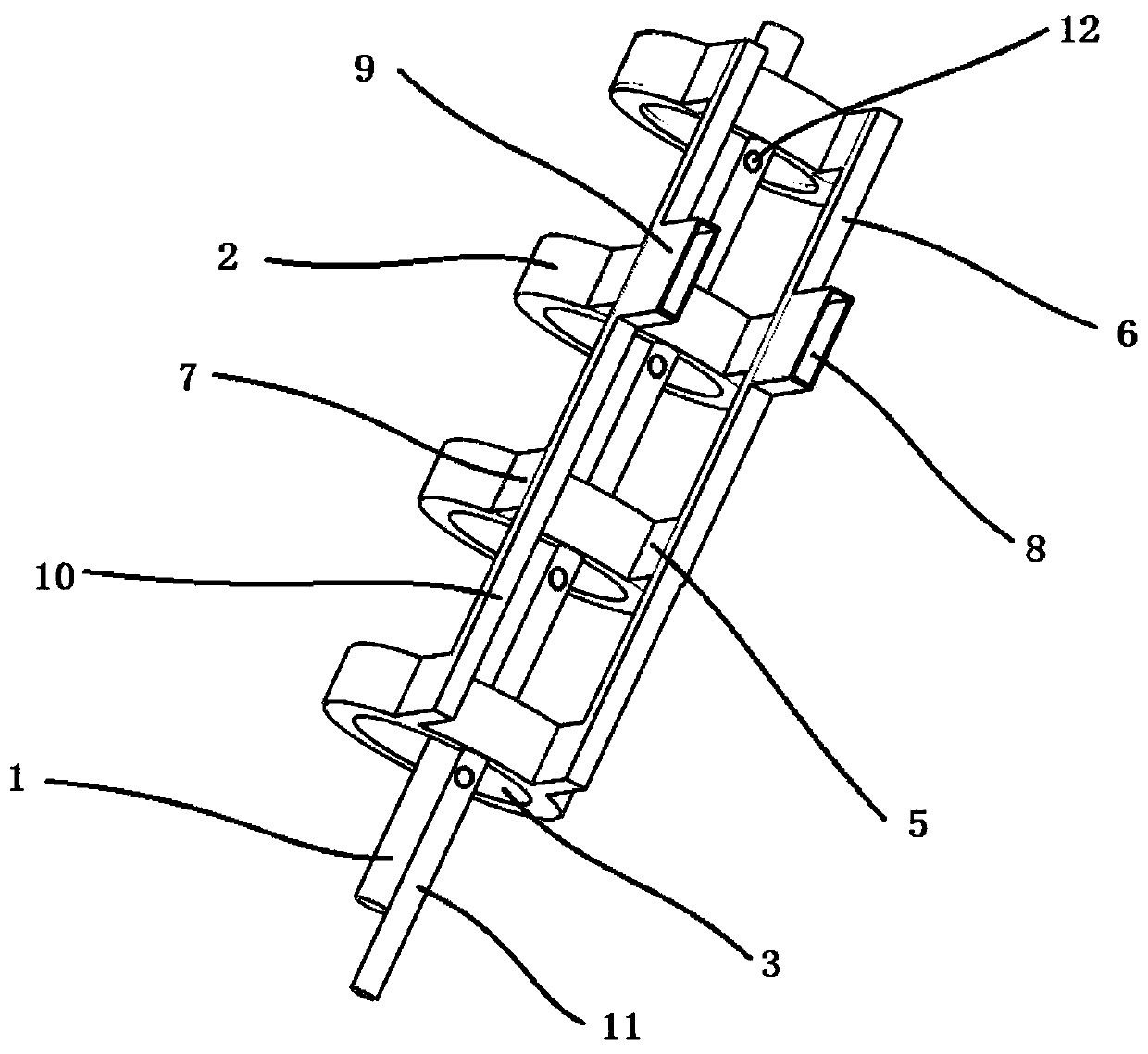

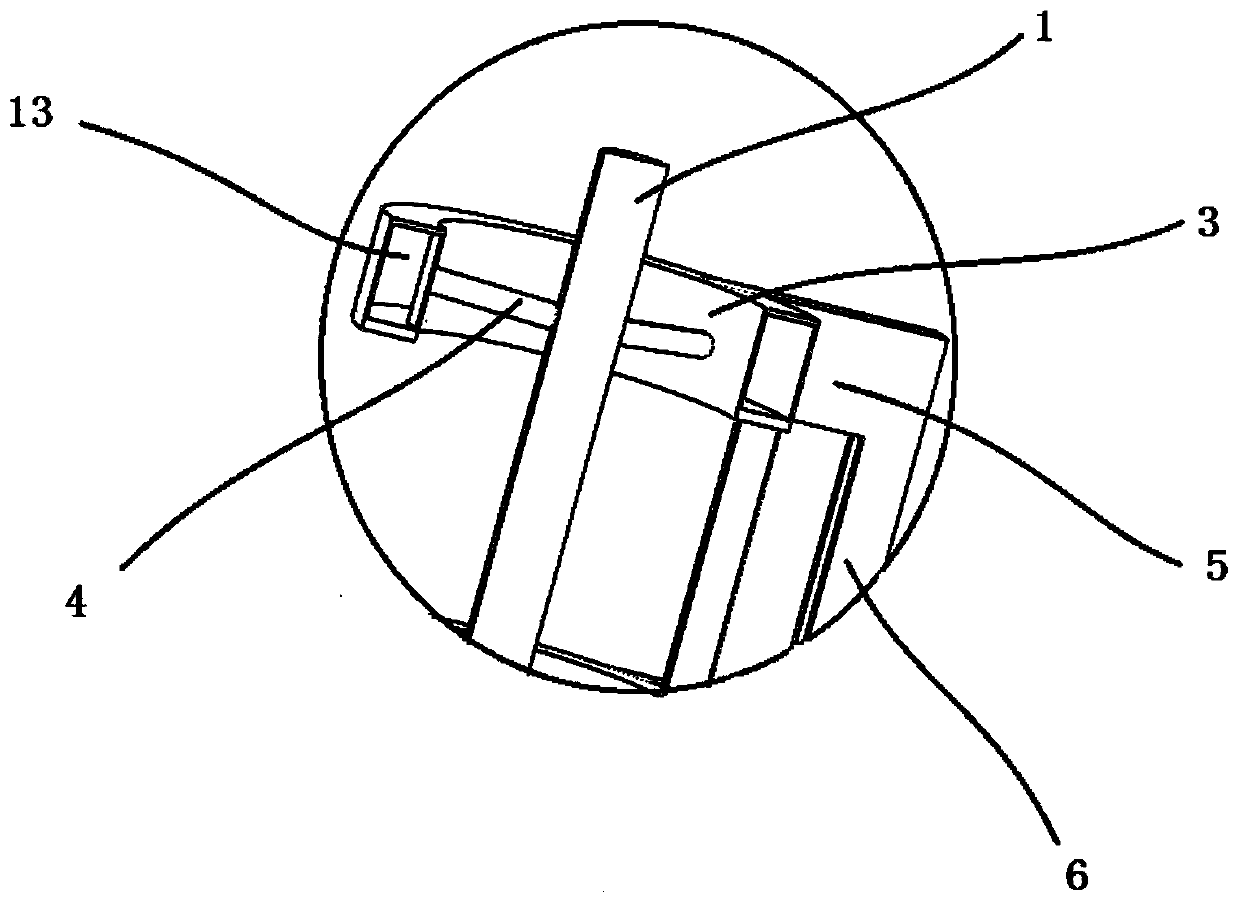

[0027] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0028] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a zeolite runner capable of intensively treating exhaust gas includes: a rotating shaft 1 , an inner casing 3 , an outer casing 2 , an air inlet channel 5 , an air outlet channel 7 and a runner 13 .

[0029] Specifically, a plurality of inner casings 3 are provided at intervals outside the rotating shaft 1, the inner casings 3 can be driven to rotate by the rotating shaft 1, a runner 13 is arranged between the inner casing 3 and the outer casing 2, and the inner casing 3 and the outer casing The connection mode of the body 2 is a movable connection. When the inner casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com