Oil product and organic chemical storage tank cleaning sewage treatment system and treatment method thereof

An organic chemical and treatment system technology, applied in the field of sewage treatment and industrial sewage treatment, can solve problems such as unsuitable development, bird death, crop production reduction, etc., and achieve intensive treatment of sewage oil and harmless sludge Improve the accuracy of dosing and prevent secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

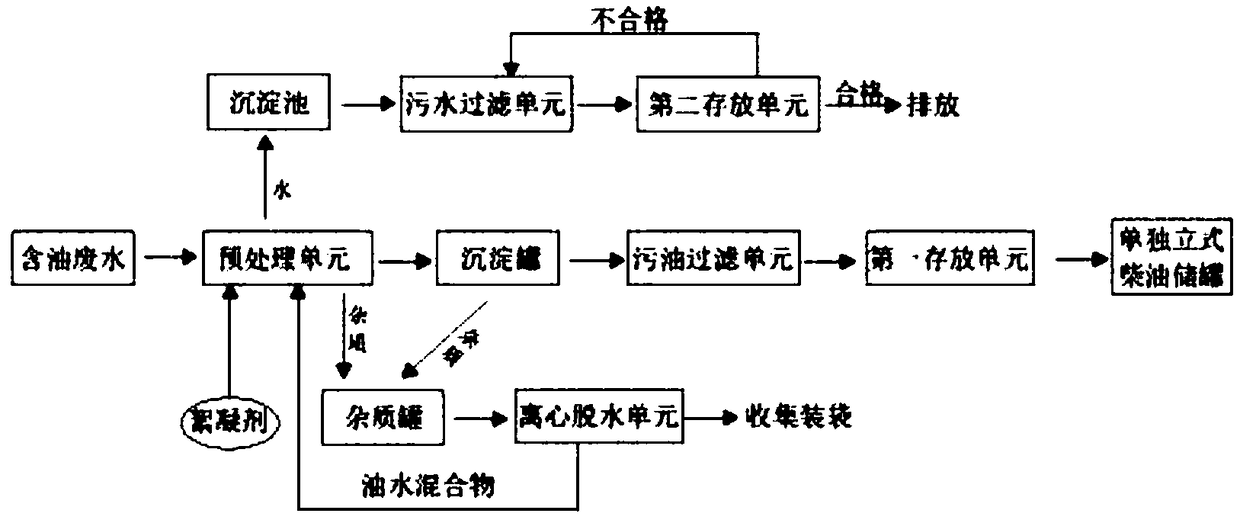

[0039] Such as figure 1 As shown, a sewage treatment system for cleaning refined oil and organic chemical storage tanks includes a parallel waste oil component treatment subsystem, a sewage component treatment subsystem and a solid component treatment subsystem. The waste oil component treatment subsystem, sewage The component processing subsystem and the solid component processing subsystem intersect and connect with the air flotation pretreatment system; the oily sewage separation treatment system is used to separate oil, water and solid impurities in the oily sewage of the air flotation pretreatment system; the oily sewage The oil, water and solid impurities in the waste water are separated and then collected and processed by the sewage component treatment subsystem, the sewage component treatment subsystem and the solid component treatment subsystem respectively.

[0040] The air flotation pretreatment system includes a pretreatment unit and an air flotation unit, the pret...

Embodiment 2

[0046] In order to describe the technical process of the present invention in more detail, a treatment process for treating oily sewage by using the above-mentioned refined oil and organic chemical storage tank cleaning sewage treatment system provided by the present invention will be described in detail below in conjunction with examples.

[0047] The Jiujiu Oil Depot began to clean the oil tanks in September 2016. After the cleaning was completed, the oily sewage produced by the 7 diesel tanks was stored in the out-of-service tank TD-02. The total height of the oil-water mixture was 2836 mm, about 78 tons. After more than a year of sedimentation, drainage was attempted, but only a small amount of clear water was discharged, so it was forced to terminate.

[0048] Beginning in April 2018, a treatment method for treating oily sewage using a refined oil and organic chemical storage tank cleaning sewage treatment system provided by the present invention includes the following ste...

Embodiment 3

[0066] In order to describe the technical process of the present invention in more detail, a treatment process for treating oily sewage provided by the present invention using the above-mentioned oily sewage treatment system will be specifically described below in conjunction with examples.

[0067] Adopt a kind of treatment system of oily waste water provided by the invention to process the treatment method of oily waste water, comprise the following steps:

[0068]Step 1: Oily waste water enters the pretreatment unit, the first pH adjustment of the oily waste water is carried out in the pretreatment unit, sodium hydroxide is added to the pretreatment unit through the dosing system, and the first pH The time of adjustment is 3h, and the pH of generating the first oily waste water is 9;

[0069] Step 2: Add a demulsifier to the first oily waste water in an amount of 10ml / L through the dosing system, and the first oily waste water is quickly mixed with the demulsifier under vig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com