Simple and rapid preparation method and application of covalent-organic framework compound solid-phase microextraction coating

A technology of covalent organic frameworks and compounds, applied in alkali metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long synthesis time period and low success rate, and achieve controllable coating thickness, simple design, Thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

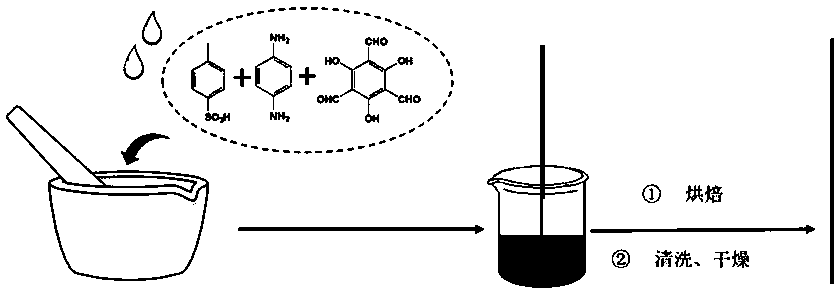

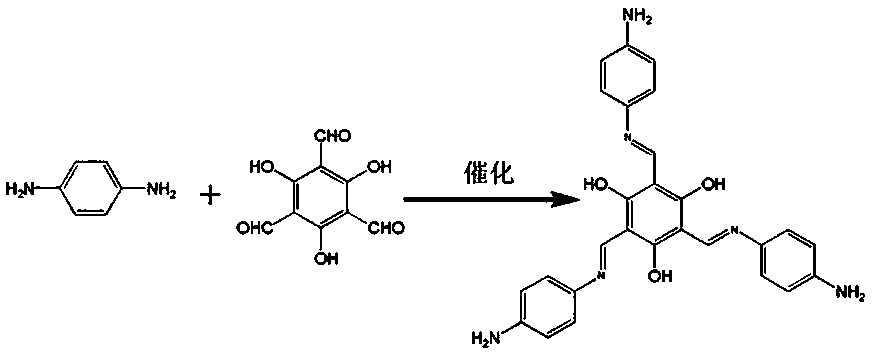

[0030] Simple and rapid preparation method of covalent organic framework compound solid phase microextraction coating and the specific operation process of applying it to sample pretreatment:

[0031] 1. A simple and rapid preparation method of a covalent organic framework compound solid-phase microextraction coating, which comprises the following steps:

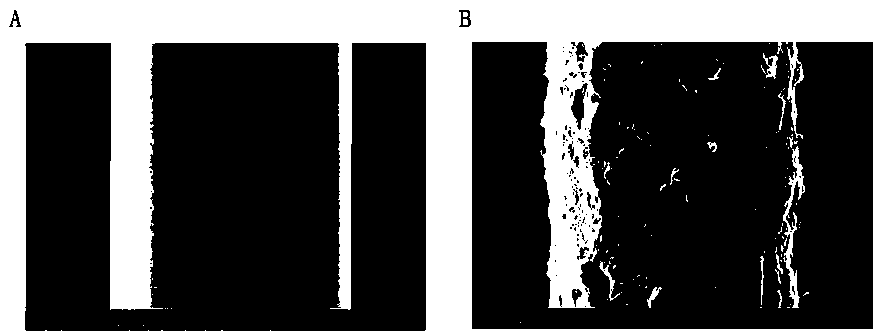

[0032] 1.1 Pretreatment of quartz fibers

[0033] (a): Take a quartz fiber with a length of 20 cm and an inner diameter of 120 μm, immerse the front end 3 cm in acetone solution for 10 minutes, peel off the polyimide coating on the surface of the fiber, wash it with deionized water three times, and dry it in the air ; (b): The exposed quartz part was activated by immersing it in a 1 M sodium hydroxide solution for 1 h, exposing a large number of silanol groups on the surface, then washing it three times with deionized water, and then immersing it in a 0.1 M hydrochloric acid solution for 15 min , remove residual lye, wash w...

Embodiment 2

[0049] A simple and rapid method for preparing a covalent organic framework compound solid-phase microextraction coating, the amine organic ligand used is 2,6-diaminoanthraquinone, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0051] A simple and rapid method for preparing a covalent organic framework compound solid-phase microextraction coating, the amine organic ligand used is 4,4'-diaminoterphenyl, and the rest of the steps are the same as in Example 1.

[0052] Table 1 shows the linear regression equation, linear correlation coefficient, linear range and detection limit for the detection of PCBs by this method

[0053]

[0054] It can be seen from the data in Table 1 that the detection linear range has a wider detection range at 5-10000 (ng / L), and the detection limit has a lower detection limit between 0.001-0.007 (ng / mL).

[0055] Table 2 is the precision inspection of SPME extracted fiber

[0056]

[0057] It can be seen from Table 2 that the precision RSD is less than 11.6%, indicating that the reproducibility of the extracted fiber is good and the coating is stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com