Porous graphene preparation method

A technology of porous graphene and organic matter, which is applied in the field of nanomaterial preparation, can solve the problems of heavy metals participating in the reaction, complicated preparation methods, environmental pollution, etc., and achieves the effects of rich species, uniform pore size distribution, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) take by weighing the glucose of 5g and the ammonium chloride of 0.5g respectively;

[0024] (2) Pour glucose and ammonium chloride into a pre-cleaned beaker, and mix uniformly to obtain a mixture of the two;

[0025] (3) The above mixture was transferred to a ceramic cup and put into a tube furnace, and the tube furnace was heated up to 1400 °C at a rate of 4 °C / min under a nitrogen atmosphere to finally prepare porous graphene.

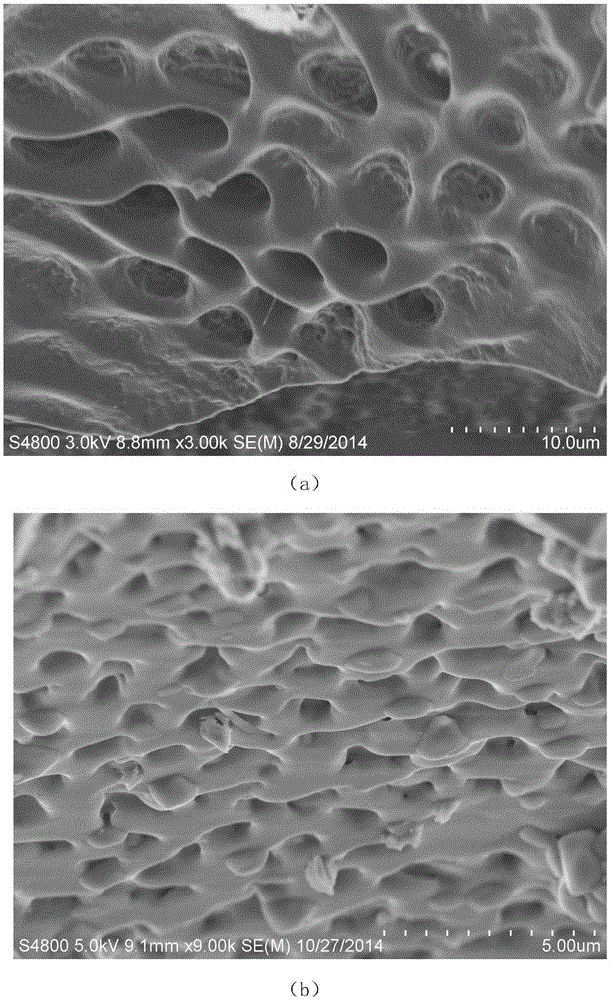

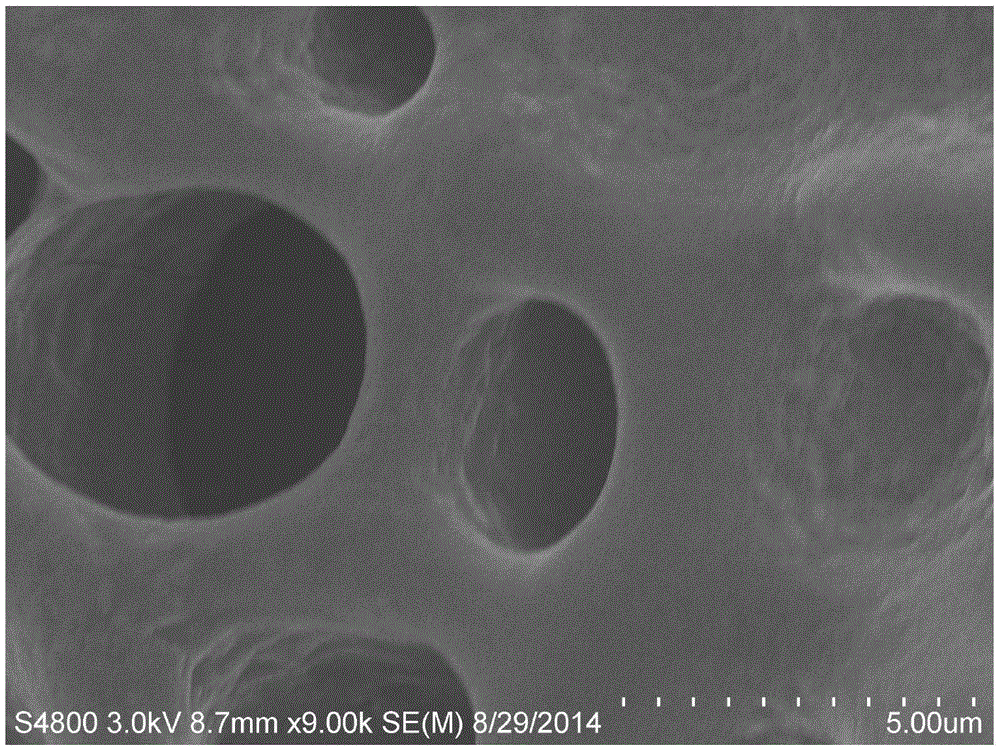

[0026] Carry out SEM electron microscope scanning analysis to the porous graphene that makes, its result is as follows figure 1 and figure 2 shown, from figure 1 In (a) and (b), it can be seen that the porous graphene pore structure prepared by this scheme is obvious, evenly distributed, and the pore size is uniform. By further zooming in and observing, as figure 2 It can be seen more clearly that the pore size is between 2-4 μm.

Embodiment 2

[0028] (1) Take by weighing 5g of glucose, 5g of calcium chloride and 4.4g of ammonium carbonate respectively

[0029] (2) Glucose, calcium chloride and ammonium carbonate are mixed uniformly to obtain a mixture;

[0030] (3) The above mixture was transferred to a ceramic cup and put into a tube furnace, and the tube furnace was heated to 900 °C at a rate of 4 °C / min under an argon atmosphere to finally prepare porous graphene.

Embodiment 3

[0032] (1) take by weighing the glucose of 1g, the ammonium chloride of 10g respectively;

[0033] (2) Glucose, graphene oxide and calcium carbonate are mixed uniformly to obtain a mixture;

[0034] (3) The above mixture was transferred to a ceramic cup and put into a tube furnace, and the tube furnace was heated up to 1400 °C at a rate of 4 °C / min under a nitrogen atmosphere to finally prepare porous graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com