Molybdenum platinum porous composite material as well as preparation method and application thereof

A porous composite material and composite material technology, which is applied in the field of electrocatalyst research, can solve the problems of hydrogen being immature, unfavorable for wide application, general performance, etc., and achieve the effects of improving application value, stable structure, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

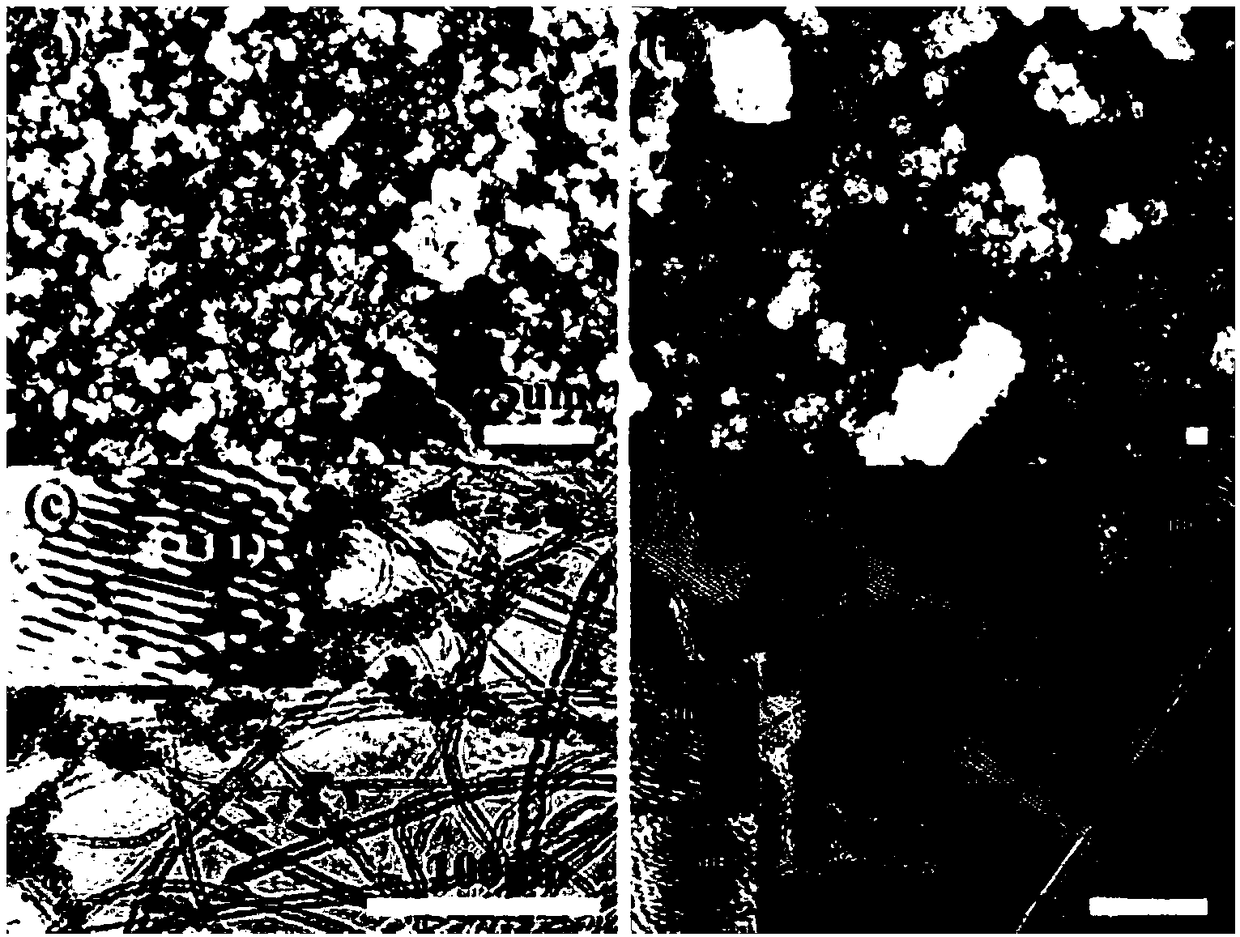

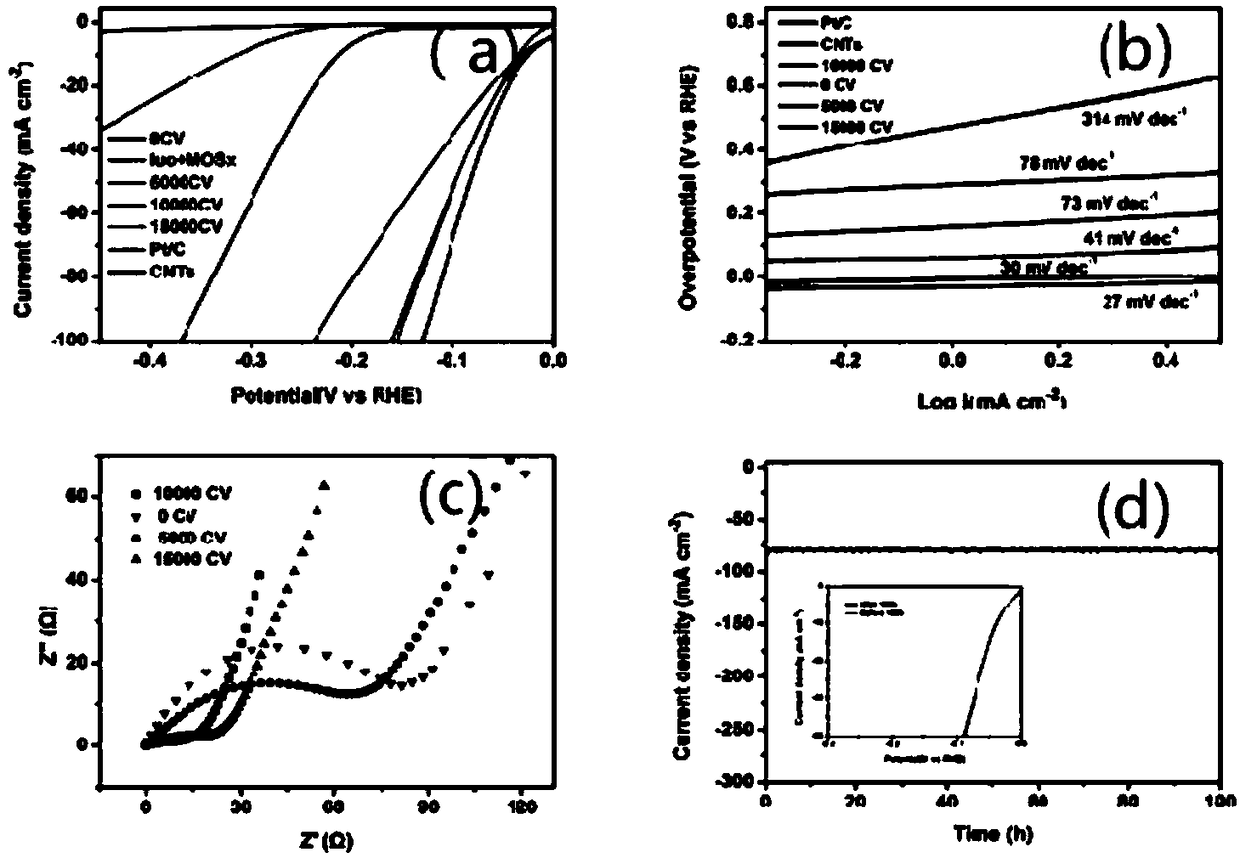

[0038] Preparation of platinum / molybdenum sulfide / carbon nanotube composites (pt-MoS x / CNTs)

[0039] (1) Electrode pretreatment: Take a glassy carbon electrode (PINE USA, rotating disk electrode, diameter 5mm), and perform polishing, washing, and 20KHz ultrasonic pretreatment for 60s in sequence;

[0040] (2) Preparation of carbon nanotube-modified glassy carbon electrodes: add a certain amount of arrayed carbon nanotubes to a mixture of ethanol and water with a volume ratio of 1:4, and ultrasonically form a suspension at 40KHz for 2 hours. Add dropwise on the surface of the glassy carbon electrode pretreated in step (1), dry naturally to form a uniform thin layer of carbon nanotubes, and obtain a carbon nanotube-modified glassy carbon electrode;

[0041] (3) Prepare the electroplating solution: add ammonium thiomolybdate and sodium perchlorate to a certain amount of deionized water, adjust the pH to 0~13 with ammonia water and hydrochloric acid, and obtain the electroplati...

Embodiment 2

[0048] Preparation of platinum / molybdenum disulfide / carbon nanotube composites (pt-MoS 2 / CNTs)

[0049] (1) Electrode pretreatment: Take a glassy carbon electrode (PINE USA, rotating disk electrode, diameter 5mm), and perform polishing, washing, and 20KHz ultrasonic pretreatment for 60s in sequence;

[0050] (2) Preparation of carbon nanotube-modified glassy carbon electrodes: add a certain amount of arrayed carbon nanotubes to a mixture of ethanol and water with a volume ratio of 1:4, and ultrasonically form a suspension at 40KHz for 2 hours. Add dropwise on the surface of the glassy carbon electrode pretreated in step (1), dry naturally to form a uniform thin layer of carbon nanotubes, and obtain a carbon nanotube-modified glassy carbon electrode;

[0051] (3) Prepare the electroplating solution: add ammonium thiomolybdate and sodium perchlorate to a certain amount of deionized water, adjust the pH to 0~13 with ammonia water and hydrochloric acid, and obtain the electropla...

Embodiment 3

[0056] Preparation of platinum-molybdenum / carbon nanotube composites (pt-Mo / CNTs)

[0057] (1) Electrode pretreatment: Take a glassy carbon electrode (PINE USA, rotating disk electrode, diameter 5mm), and perform polishing, washing, and 20KHz ultrasonic pretreatment for 60s in sequence;

[0058] (2) Preparation of carbon nanotube-modified glassy carbon electrodes: add a certain amount of arrayed carbon nanotubes to a mixture of ethanol and water with a volume ratio of 1:4, and ultrasonically form a suspension at 40KHz for 2 hours. Add dropwise on the surface of the glassy carbon electrode pretreated in step (1), dry naturally to form a uniform thin layer of carbon nanotubes, and obtain a carbon nanotube-modified glassy carbon electrode;

[0059] (3) Prepare the electroplating solution: add potassium molybdate and sodium perchlorate to a certain amount of deionized water, adjust the pH to 0~13 with ammonia water and hydrochloric acid, and obtain the electroplating solution 0-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com