Silica heat-insulation composite material and preparation method thereof

A technology of silica and composite materials, applied in the field of thermal insulation materials, can solve the problems of cumbersome, easy-to-drop powder preparation methods, and high brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

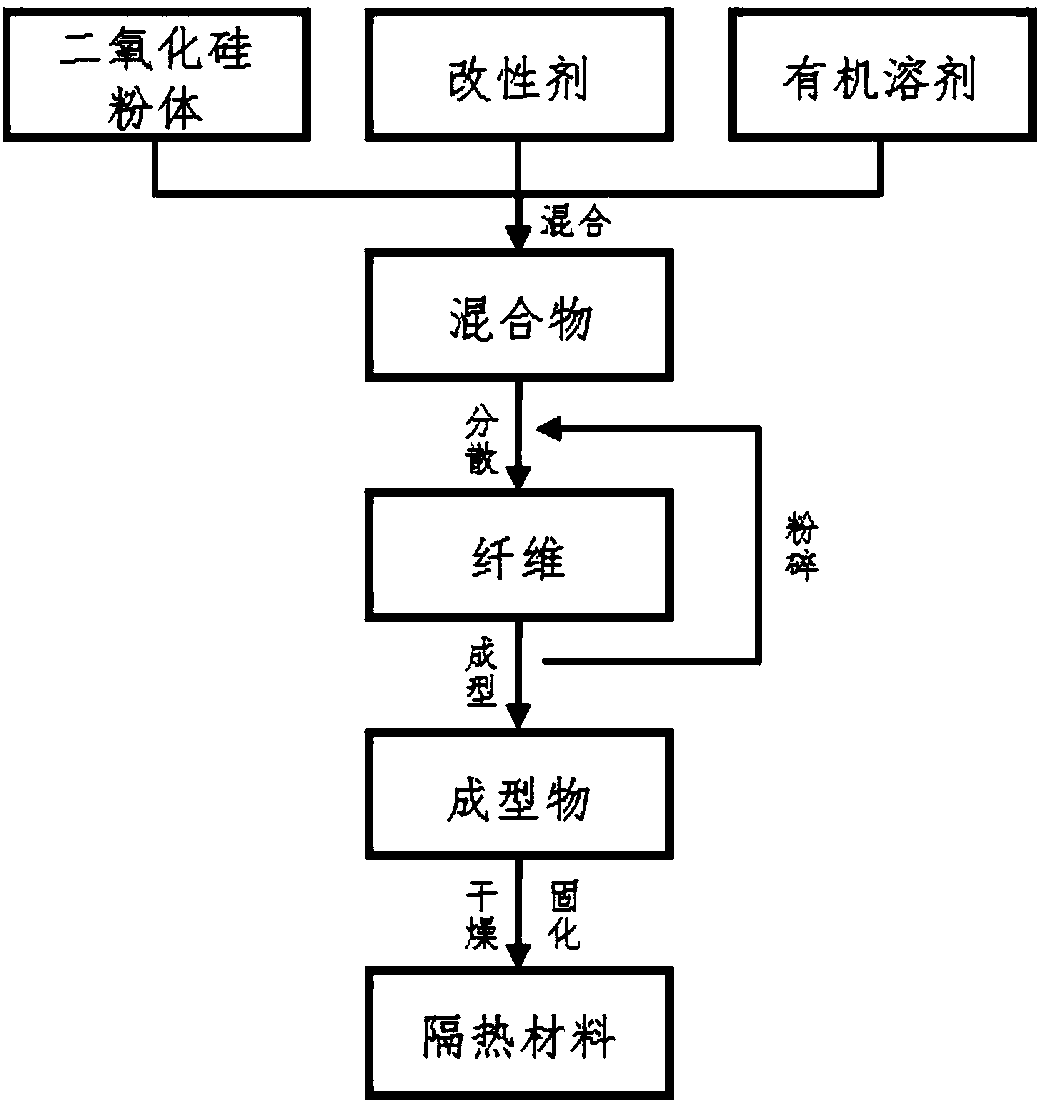

[0067] The preparation method of a kind of silicon dioxide thermal insulation composite material of the present invention, according to the attached figure 1 The described process includes the following steps:

[0068] 1) In a 1.5L stirrer, put 500 parts of methanol, 20 parts of 3-aminopropyltrimethoxysilane, and 3 parts of methyltrimethoxysilane in sequence;

[0069] 2) Slowly add 500 parts of fumed silica powder to the above-mentioned agitator, stir evenly to obtain a viscous mixture, place it at room temperature for a period of time, and set aside;

[0070] 3) Take glass fiber and add it to the above-mentioned agitator. The length of the glass fiber is 30 mm, the diameter of a single fiber is 8-12 μm, and the mass fraction of the glass fiber is 70 parts. When adding, the agitator is in a slow stirring state. Slowly add to the blender, after the addition is complete, continue to stir to obtain a paste mixture;

[0071] 4) Continue crushing, extruding and stirring the above...

Embodiment 2

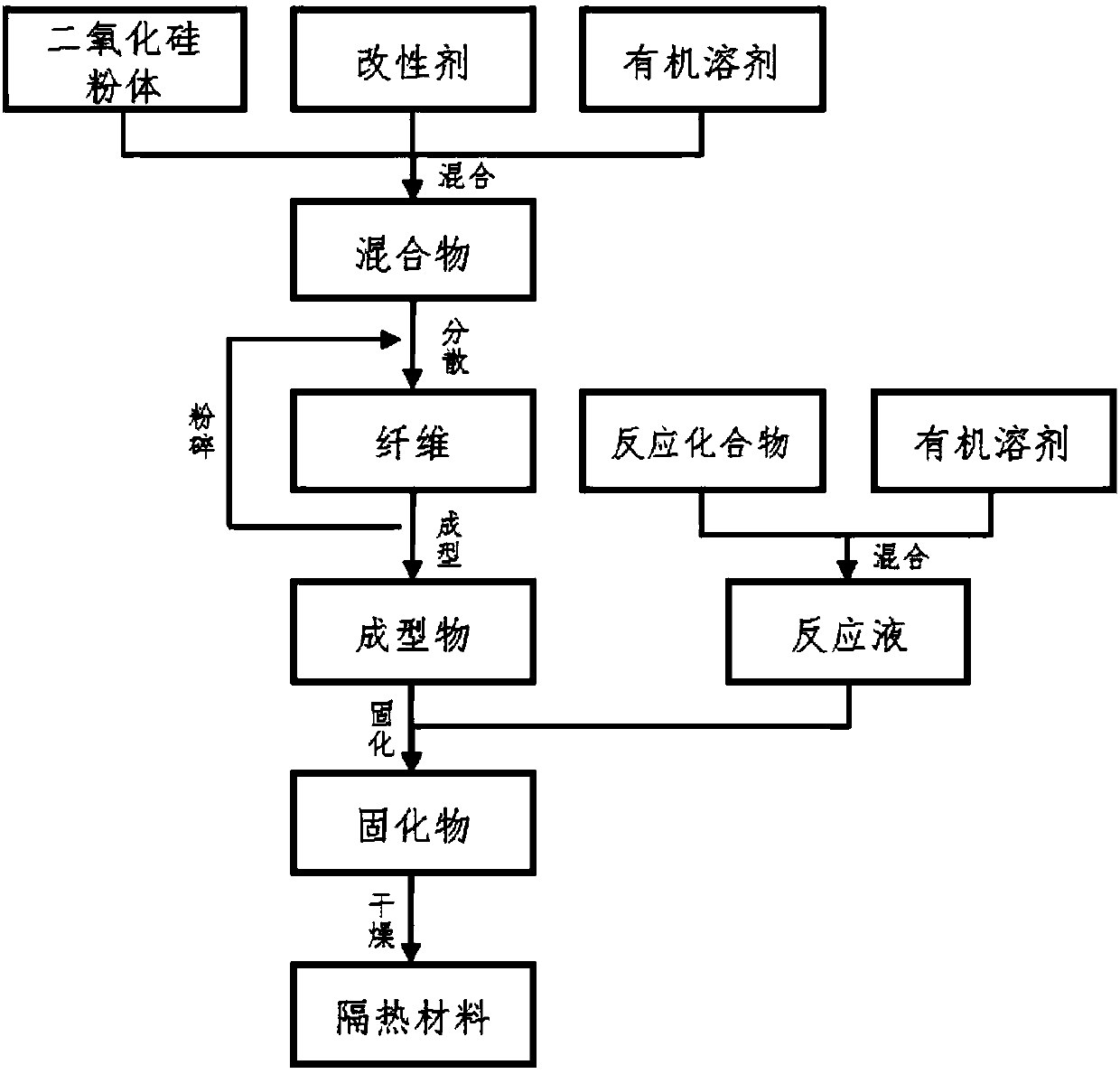

[0075] A method for preparing a silica heat-insulating composite material of the present invention comprises the following steps:

[0076] 1) In a 1.5L stirrer, add ethanol, dimethyl sulfoxide, γ-glycidyl etheroxypropyl trimethoxysilane, and dimethyldimethoxysilane in sequence, and the addition amounts are 200 parts and 300 parts respectively parts, 90 parts, and 5 parts, stir to make it evenly mixed, and put it in the refrigerator;

[0077] 2) When the temperature of the liquid in the above-mentioned refrigerator is 0°C, take out the liquid from the refrigerator, slowly add 10 parts of microcrystalline cellulose into the stirrer to obtain a cloudy liquid, and stir at a high speed of 1500 rpm for 20 minutes ;

[0078] 3) Slowly add 600 parts of silica powder to the mixed liquid obtained in step 2), and stir to obtain a viscous liquid mixture, which is defoamed by a defoaming machine;

[0079] 4) Take the thickness as 5mm and the density as 0.12g / cm 3 The glass fiber felt is...

Embodiment 3

[0083] In the preparation method of a silica heat-insulating composite material of the present invention, on the basis of Example 1, the glass fiber is replaced with activated carbon filter cotton, the activated carbon filter cotton has a diameter of 11-18 μm and a specific surface area of 800-1600 m 2 / g, single fiber length 3-5mm, carbon content ≥ 80%; On the basis of embodiment 1, the organic solvent is changed from methanol to ethanol, wherein, the index of ethanol is: ethanol content ≥ 95%, the quality of water Fraction ≤ 0.3%, the mass fraction of methanol ≤ 0.05%, the mass fraction of isopropanol ≤ 0.01%.

[0084] The thermal insulation composite board obtained in this example has a smooth surface, certain elasticity and flexibility, and a density of 0.2g / cm 3 , When vibrating under the pressure of 3MPa, no dust falls, the strain energy is 1.5MPa when the compressive strength is 10%, and the thermal conductivity is 0.025W / m·k.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com