Porous integral medium, preparation and use thereof

A medium and overall technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problem of uneven distribution of surface functional groups, inaccurate control of pore size distribution, and reduced mechanical properties of materials and other problems, to achieve the effect of excellent permeability, excellent mechanical stability and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Preparation of the first part of porous monolithic media

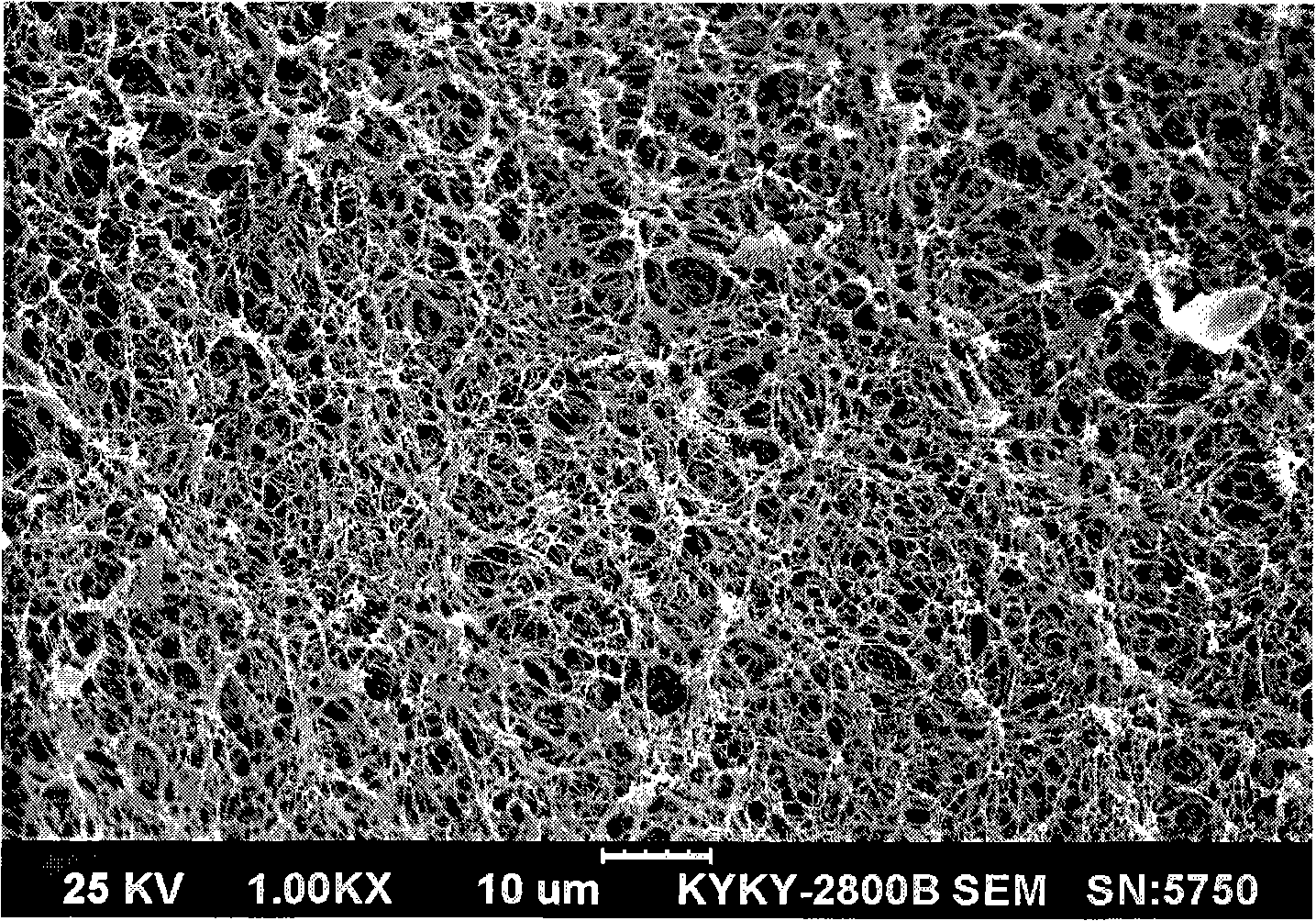

[0026] The invention adopts the super-concentrated emulsion polymerization method to control the composition of the super-concentrated emulsion in the reaction system and the phase separation process, thereby preparing a porous monolithic medium with a nanowire network skeleton structure. The porous monolithic medium has a regular nanowire network skeleton and a micron-scale through-hole structure, the skeleton size is between 50-500nm, the porosity is between 60%-95%, and the through-pore diameter is between 1-100μm, which can be continuously adjusted . The porous monolithic medium has an internal pore structure arranged in an orderly manner, and the pores communicate with each other, and the form can be a continuous rod or a continuous integral film. The specific surface area of the porous monolithic medium of the present invention is large, between 100-350m 2 g -1 , with excellent permeability and excell...

Embodiment 1

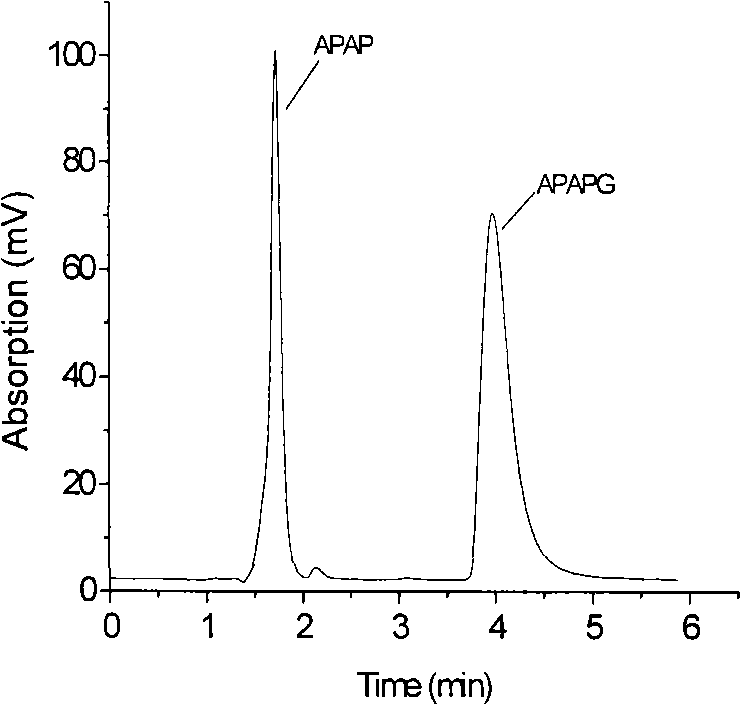

[0037] Embodiment 1: Preparation of glycidyl methacrylate monolithic separation medium

[0038] At room temperature, 14.5g glycidyl methacrylate (GMA), 6.70g ethylene glycol methacrylate (EDMA) and 2.68g Synperonic PEL 121 were placed in a dry three-necked flask equipped with mechanical stirring at 550rpm Stir, and then 95ml containing 0.2% potassium persulfate (quality) and 2% CaCl 2 ·6H 2 O (mass) deionized aqueous solution was added dropwise into a three-necked flask by dropping while stirring, and the dropping speed was controlled to prevent phase separation, and the ultra-concentrated emulsion could be obtained by continuing for 20-30 minutes.

[0039] Transfer the ultra-concentrated emulsion into a centrifuge test tube, centrifuge at 300r / min for 2min to remove oxygen, and then pass in nitrogen gas to seal for 15min. Then, put the mixed solution into a dry mold, seal it and place it in a water bath at 55°C for 48 hours, then use excess deionized water and ethanol to wa...

Embodiment 2

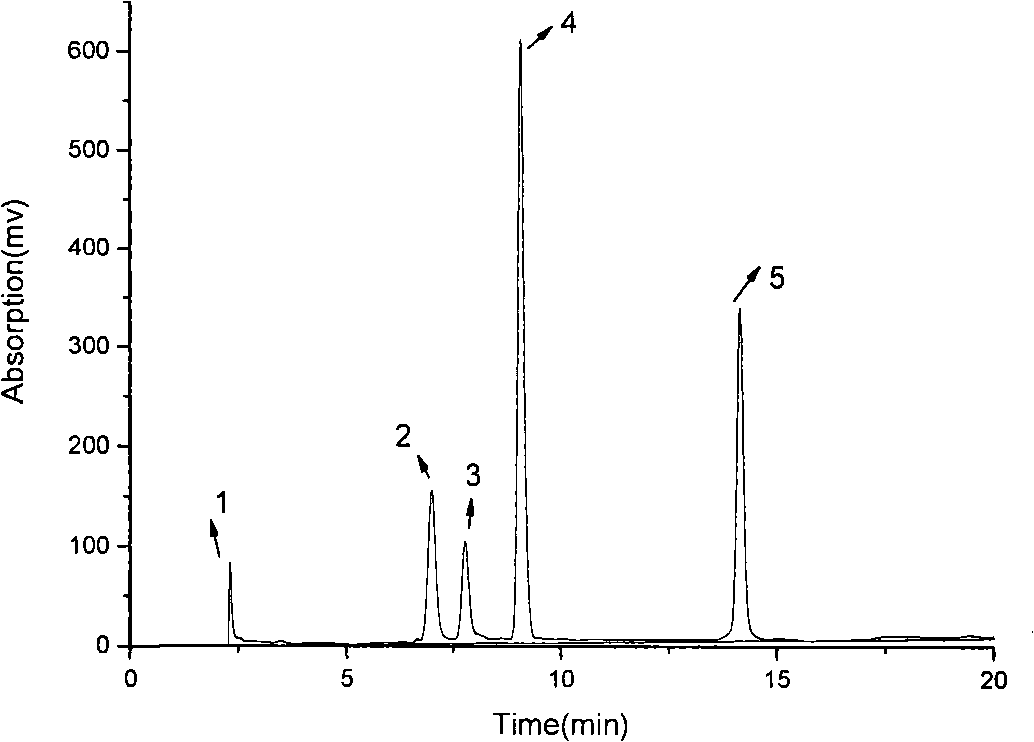

[0041] Embodiment 2: Preparation of glycidyl methacrylate monolithic separation medium

[0042] At room temperature, 13.2g of glycidyl methacrylate (GMA), 7.20g of ethylene glycol methacrylate (EDMA) and 3.68g of Pluronic F127 were placed in a dry three-necked flask equipped with mechanical stirring at a speed of 550rpm. Stir, and then 80ml containing 0.2% ammonium persulfate (mass) and 1.2% K 2 SO 4 (mass) of deionized aqueous solution is added dropwise into a three-necked flask by dropping while stirring, and the dropping speed is controlled to prevent phase separation, and the ultra-concentrated emulsion can be obtained by continuing for 20 to 30 minutes.

[0043] Transfer the ultra-concentrated emulsion into a centrifuge test tube, centrifuge at 300r / min for 2min to remove oxygen, and then pass in nitrogen gas to seal for 15min. Then, put the mixture into a dry mold, seal it and place it in a water bath at 60°C for 36 hours, then use excess deionized water and methanol t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com