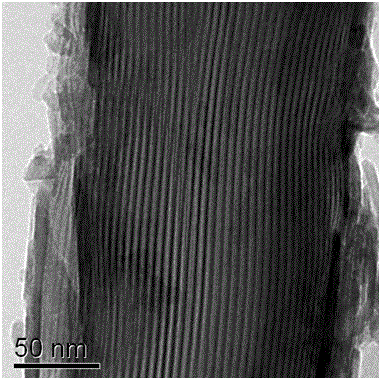

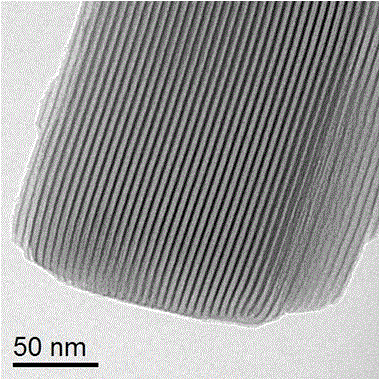

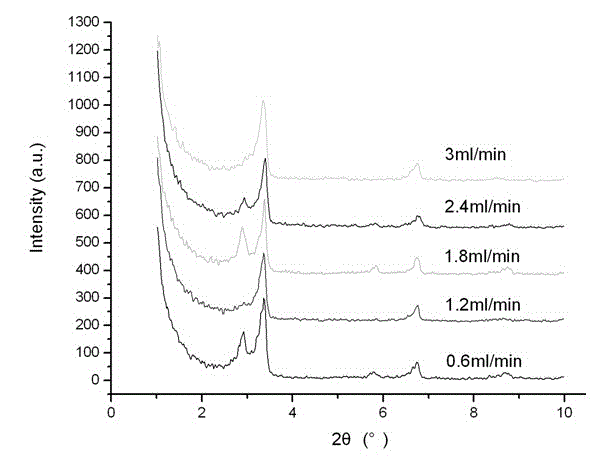

Preparation method of laminar nanometer hydroxylapatite with controllable pore diameter

A hydroxyapatite and layered nanotechnology, which is applied in the field of preparation of layered nano-hydroxyapatite, can solve the problems of wide pore size distribution, disordered mesoporous channels, and high cost, and achieves narrow pore size distribution and high production cost. Simple method and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Prepare 0.3mol / L calcium nitrate tetrahydrate solution and stir for 10 minutes;

[0016] 2) Dissolve 1.25g of potassium monododecyl phosphate in 15mL of water and 30mL of absolute ethanol, and stir for 15min;

[0017] 3) Manually add the potassium monododecyl phosphate solution into the calcium salt solution dropwise, and stir for 20 minutes;

[0018] 4) Prepare 0.05mol / L diammonium hydrogen phosphate solution, stir for 10 minutes, manually drop it into the above mixed solution, stir for 30 minutes, and form an emulsion;

[0019] 5) Use 6mol / L sodium hydroxide to adjust the pH of the emulsion to 10, continue stirring for 4 hours, and heat at 90°C for 10 hours;

[0020] 6) Washing and drying by centrifugation to obtain layered nano-hydroxyapatite.

Embodiment 2

[0022] 1) Prepare 0.45mol / L calcium nitrate tetrahydrate solution and stir for 10 minutes;

[0023] 2) Dissolve 2.5g of potassium monododecyl phosphate in 15mL of water and 30mL of absolute ethanol, and stir for 15min;

[0024] 3) Manually add the potassium monododecyl phosphate solution into the calcium salt solution dropwise, and stir for 25 minutes;

[0025] 4) Prepare 0.1mol / L diammonium hydrogen phosphate solution, stir for 10 minutes, manually drop it into the above mixed solution, stir for 30 minutes, and form an emulsion;

[0026] 5) Use 6mol / L sodium hydroxide to adjust the pH of the emulsion to 8, continue stirring for 4 hours, and heat at 90°C for 12 hours;

[0027] 6) Washing and drying by centrifugation to obtain layered nano-hydroxyapatite.

Embodiment 3

[0029] 1) Prepare 0.5mol / L calcium nitrate tetrahydrate solution and stir for 10 minutes;

[0030] 2) Dissolve 2.5g of sodium monododecyl phosphate in 15mL of water and 30mL of absolute ethanol, and stir for 15min;

[0031] 3) Manually add the sodium monododecyl phosphate solution into the calcium salt solution dropwise, and stir for 20 minutes;

[0032] 4) Prepare 0.08mol / L diammonium hydrogen phosphate solution, stir for 10 minutes, manually drop it into the above mixed solution, stir for 45 minutes to form an emulsion;

[0033] 5) Use 7mol / L sodium hydroxide to adjust the pH of the emulsion to 10, continue stirring for 4 hours, and heat at 90°C for 6 hours;

[0034] 6) Washing and drying by centrifugation to obtain layered nano-hydroxyapatite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com